Water pre-injection type double-seal pedestal pan

A toilet and double-seal technology, which is applied in the field of sanitary cleaning appliances, can solve the problems of mechanical seal valve opening lag, waste, and insufficient, and achieve the effect of solving the problem of constant water seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

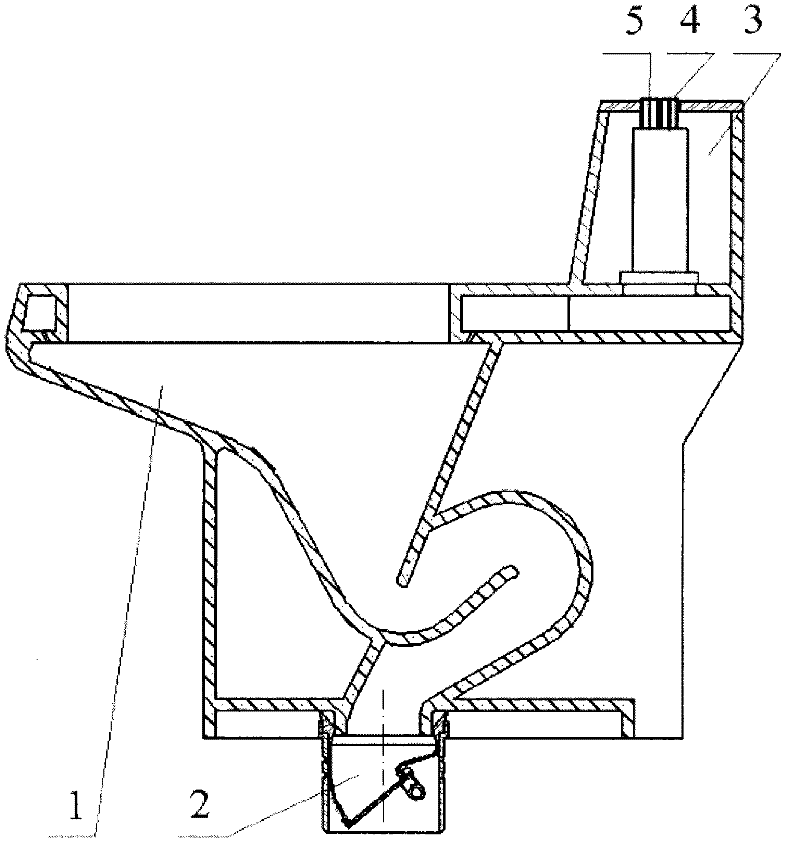

[0155] like figure 1 As shown, the water tank 3 is connected with the toilet body 1 and is arranged above the toilet body 1. The upper part of the water tank 3 has a pre-fill switch 4 and a flush switch 5, and the water flow is made by the pre-fill switch 4 and the flush switch 5. Flush into the toilet main body 1 through the flushing hole on the water distribution ring of the toilet main body 1. The flushing holes on the water distribution ring of the toilet main body 1 have different aperture sizes, and the closer to the front end of the water distribution ring, the larger the diameter of the flushing hole , the maximum aperture is about 3 times the minimum aperture, so that the flushing water can evenly flush the inner wall of the toilet body 1, and the opening direction of the flushing hole is 45 degrees in the clockwise direction, so that the flushing water enters the toilet body 1 and rotates clockwise direction to form a swirl, prolong the flow time of the flushing wate...

Embodiment 2

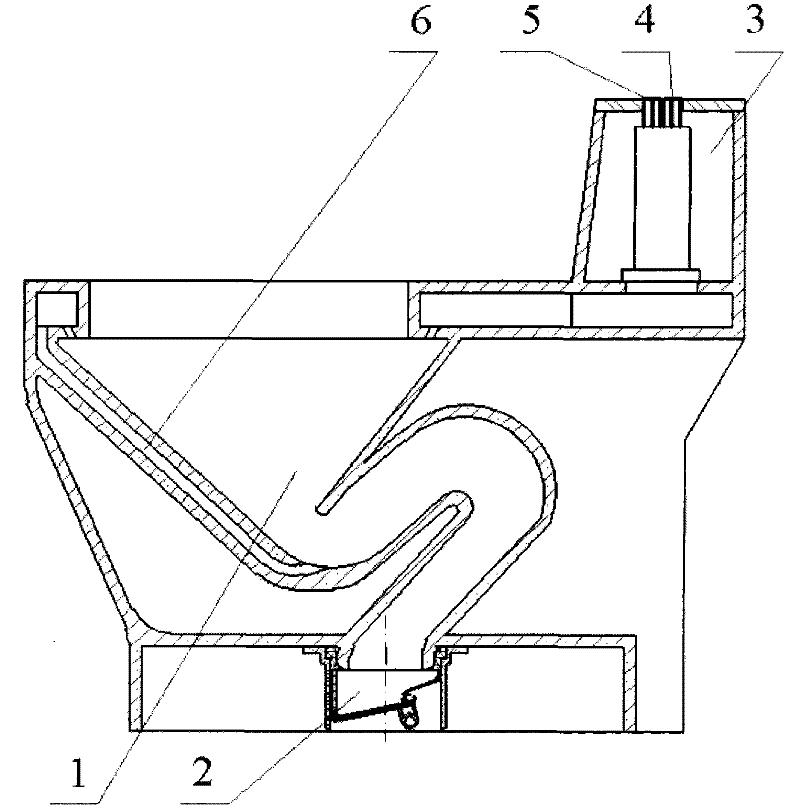

[0157] like figure 2 As shown, the water tank 3 is connected with the toilet body 1 and is arranged above the toilet body 1. The upper part of the water tank 3 has a pre-fill switch 4 and a flush switch 5, and the water flow is made by the pre-fill switch 4 and the flush switch 5. Enter the toilet body 1 through the flushing hole on the water distribution ring of the toilet body 1 and the nozzle of the flushing jet pipe 6; the trap water seal depth of the toilet body 1 is 30mm, and the water distribution ring of the toilet body There is a flush jet pipe 6 between the bottom of the trap and the bottom of the trap; the mechanical seal valve 2 is located below the trap, the mechanical seal valve 2 is connected to the sewage outlet of the toilet body 1, and the mechanical seal valve 2 is directly installed on the seat The toilet body 1 is integrally assembled; the mechanical seal valve 2 is a magnetic seal flat valve made of polytetrafluoroethylene material, which can provide a w...

Embodiment 3

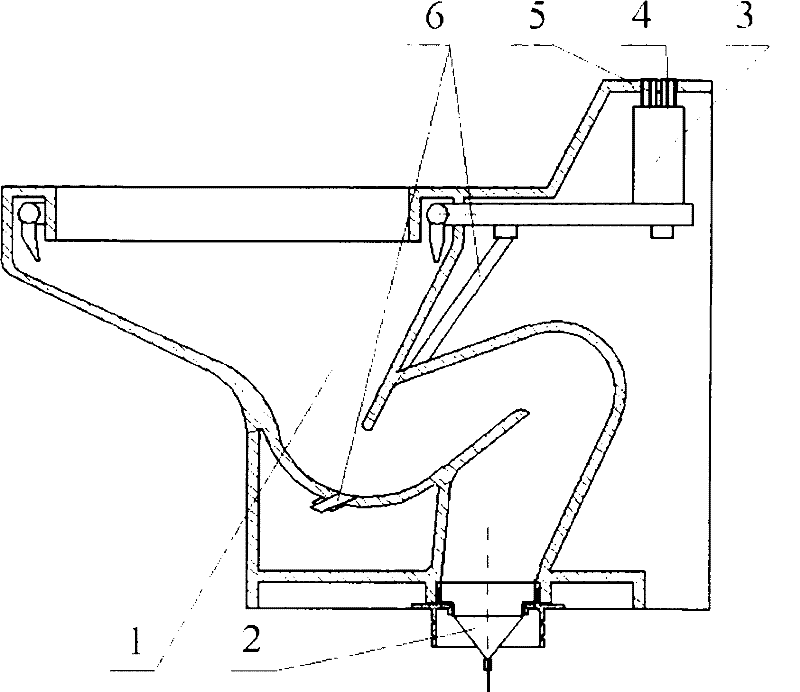

[0159] like image 3 As shown, the water supply device 3 is connected with the toilet body 1 and is arranged at the rear of the toilet body 1. The water supply device 3 has a prefill water switch 4 and a flush switch 5. The water supply device 3 also has a water inlet and an outlet. The water inlet, the water inlet is connected to the tap water pipe through a flexible pipe, and the water outlet is connected to three nozzles through a flexible pipe or a hard pipe, a plastic pipe or a stainless steel pipe, wherein the two nozzles installed on the top of the toilet body 1 are flushing nozzles, installed on the One nozzle at the lower part of the toilet body 1 is a spray nozzle, and two flushing nozzles are installed at the front and rear ends of the water distribution ring through the pipes installed in the water distribution ring, and the water outlets of the two flushing nozzles are 45 degrees in the counterclockwise direction , so that the flushing water enters the toilet body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com