System and method for testing all-weather tyre tread-road surface frictional characteristic

A tire tread and friction characteristics technology, applied in the field of tire tribology research, can solve problems such as unrealized automation, rapid heat generation, and influence on the accuracy of measurement results, so as to improve repeatability and accuracy and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

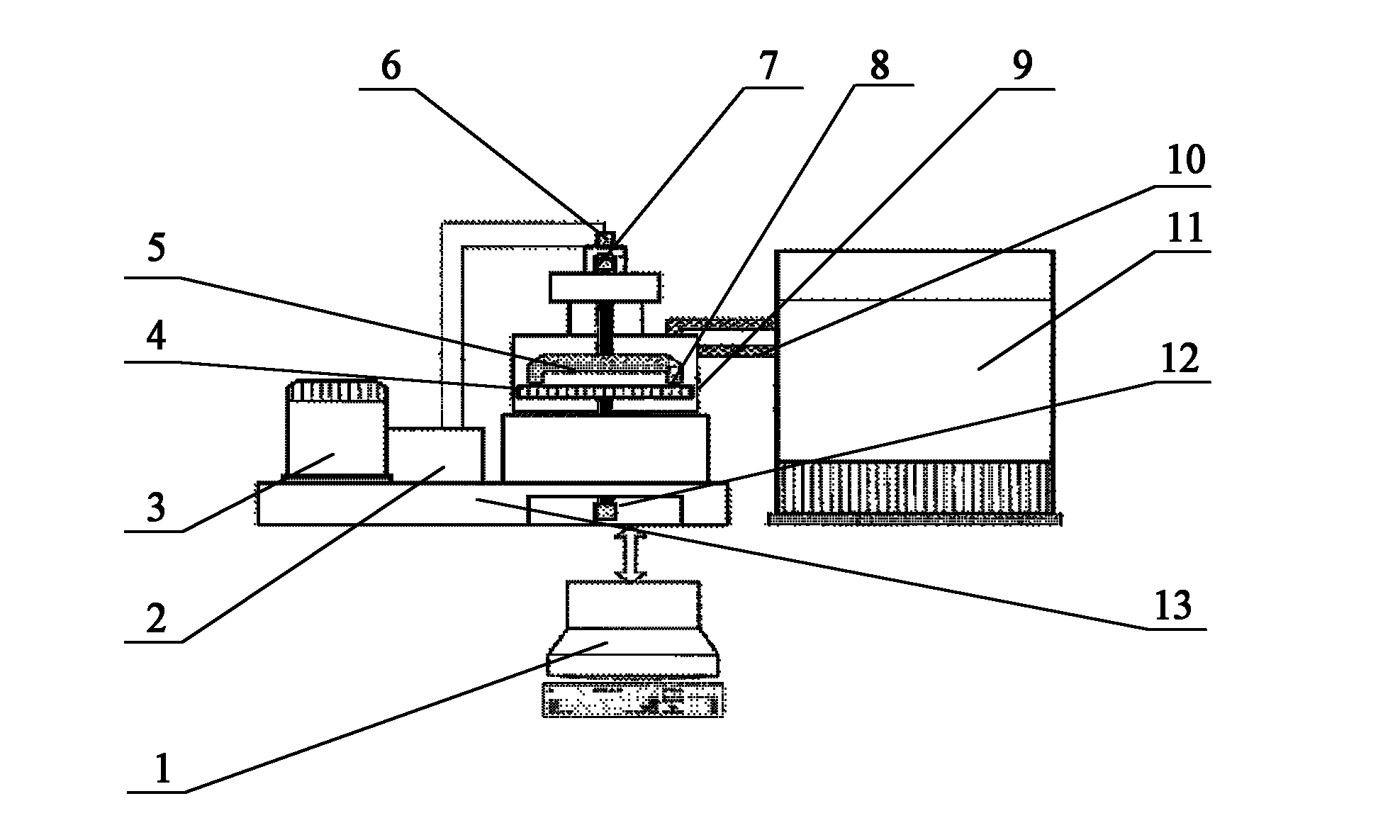

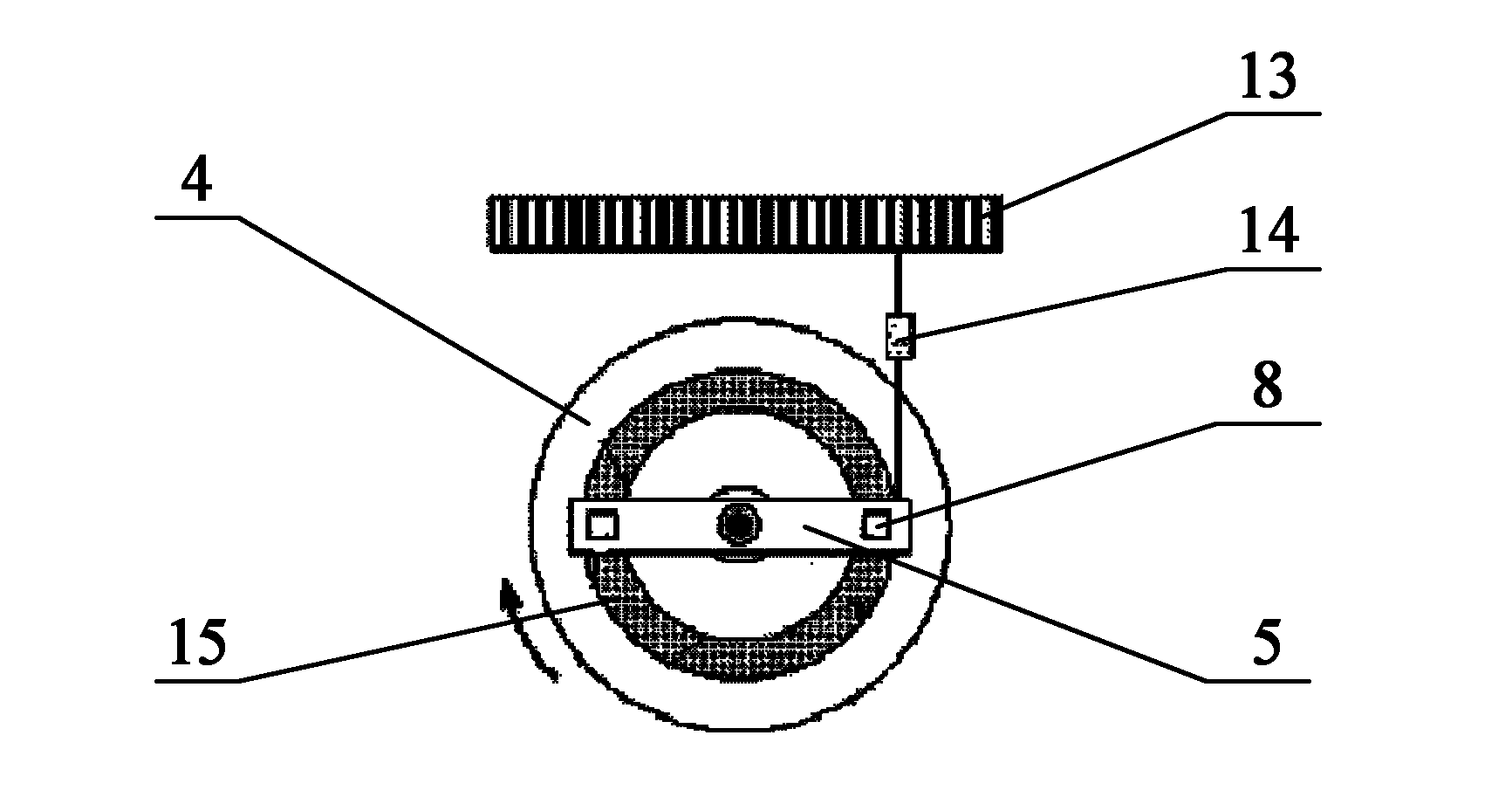

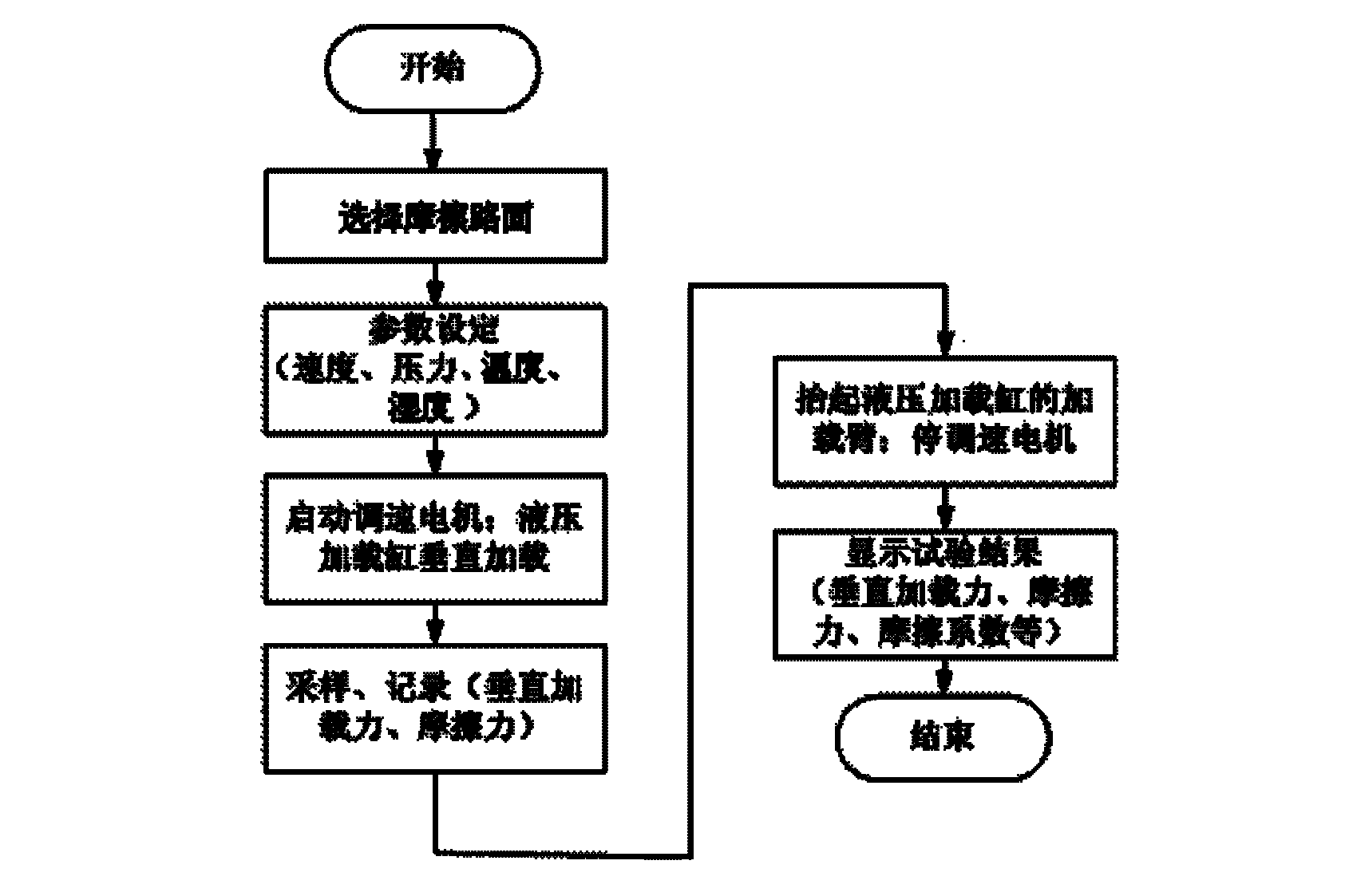

[0039] The technical scheme of the present invention will be further introduced below in conjunction with the accompanying drawings:

[0040] Such as figure 1 As shown, the all-weather tire tread-road friction characteristic test system of the present invention includes: console 1, hydraulic source 2, speed regulating motor 3, rotating disc 4, pressure disc 5, hydraulic loading cylinder 6, vertical pressure sensor 7. Tire interview block 8, environmental chamber 9, air duct 10, environmental control unit 11, speed sensor 12, main frame 13, horizontal tension and compression sensor 14, friction road surface 15.

[0041] Among them, the console 1 is respectively connected to the control speed regulating motor 3, the hydraulic loading cylinder 6, and the environmental control unit 11 through a data cable;

[0042] The hydraulic source 2 is connected to the hydraulic loading cylinder 6 through a hydraulic oil pipe to provide hydraulic power for it;

[0043] The speed-regulating motor 3 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com