Fly-eye lens

A fly-eye lens and micro-lens technology, applied in the direction of lenses, lighting and heating equipment, instruments, etc., can solve the problems of reducing the uniformity of the light field, failing to realize the output light field, and unfavorable utilization of illumination light, so as to improve the light energy Effect of utilization, avoidance of light energy loss and stray light on uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

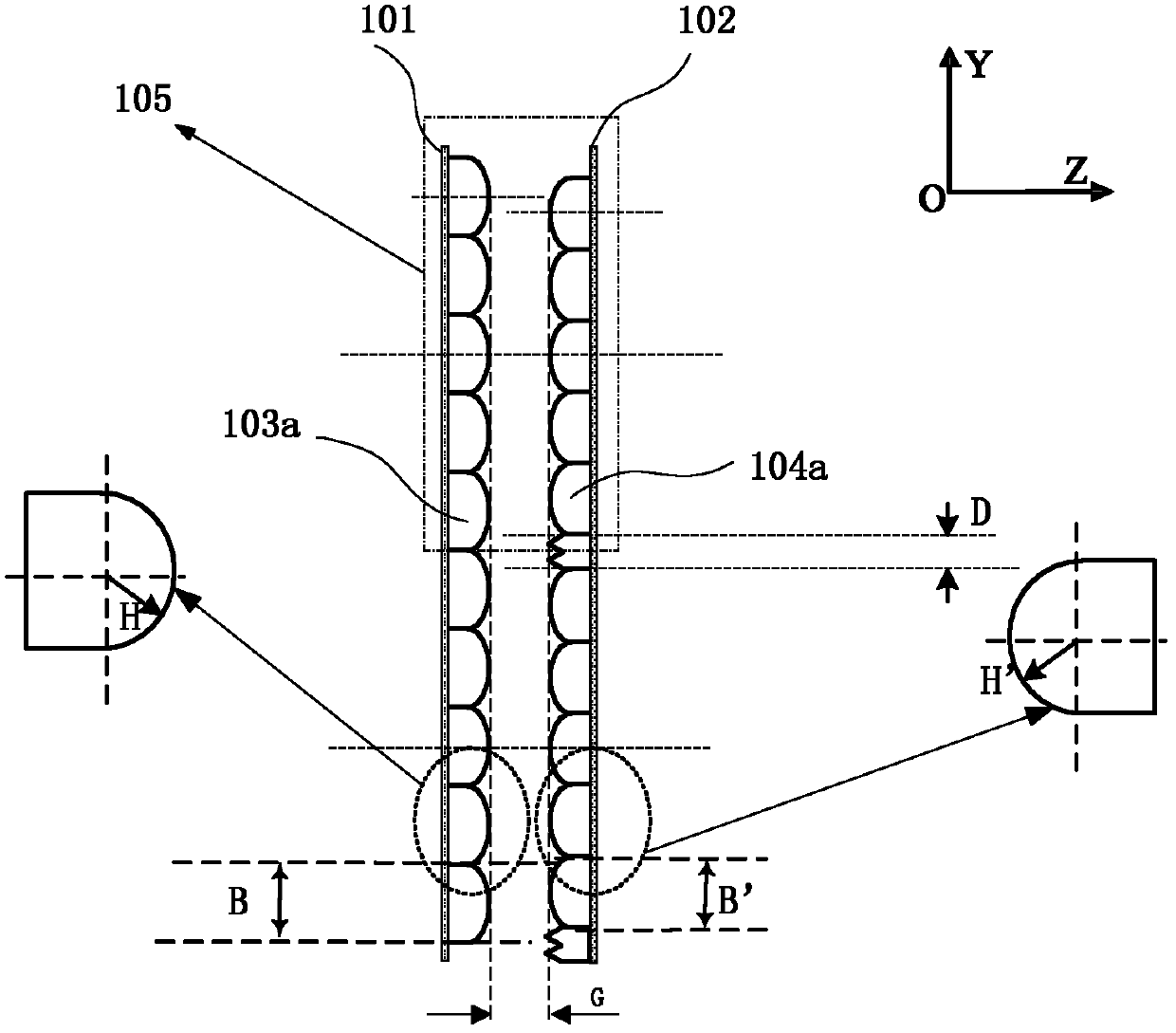

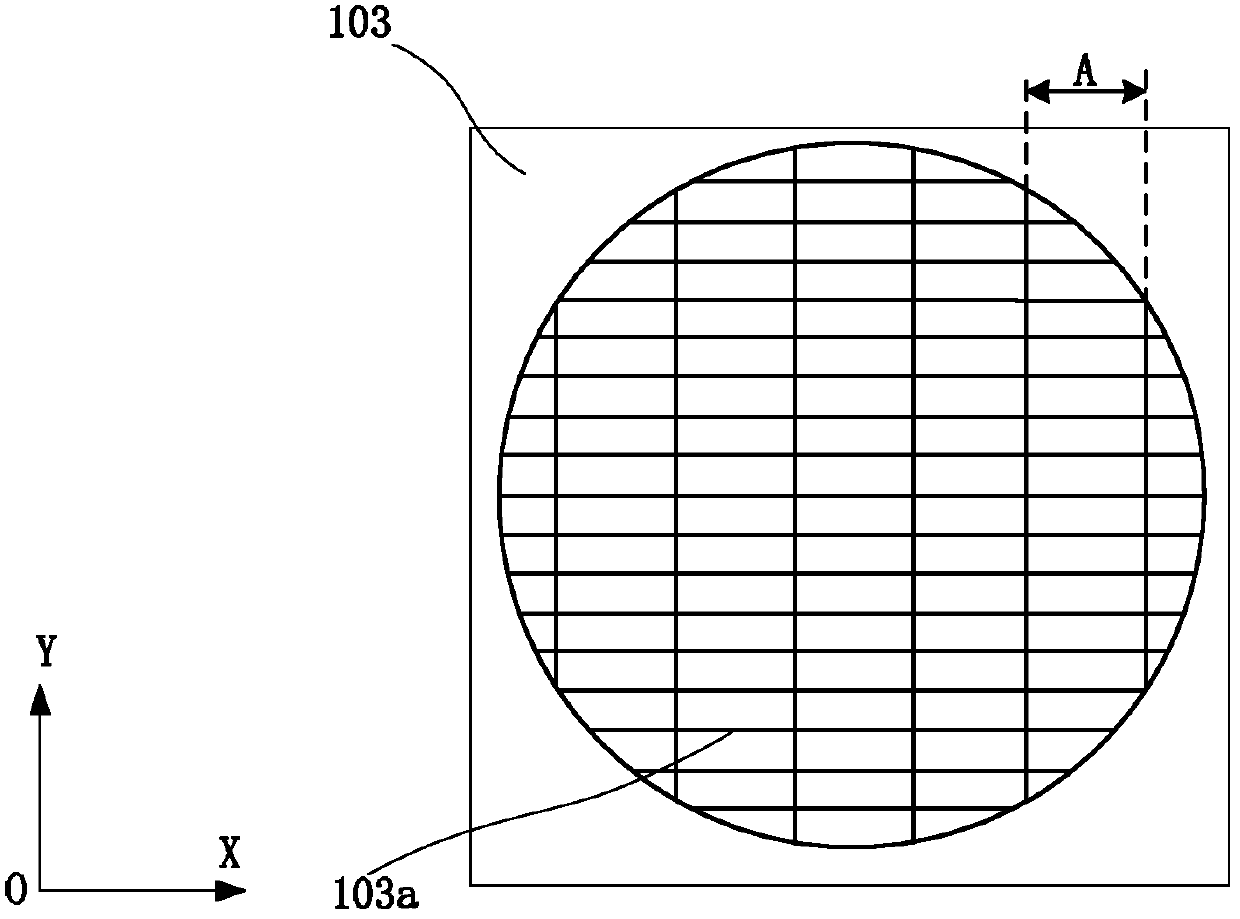

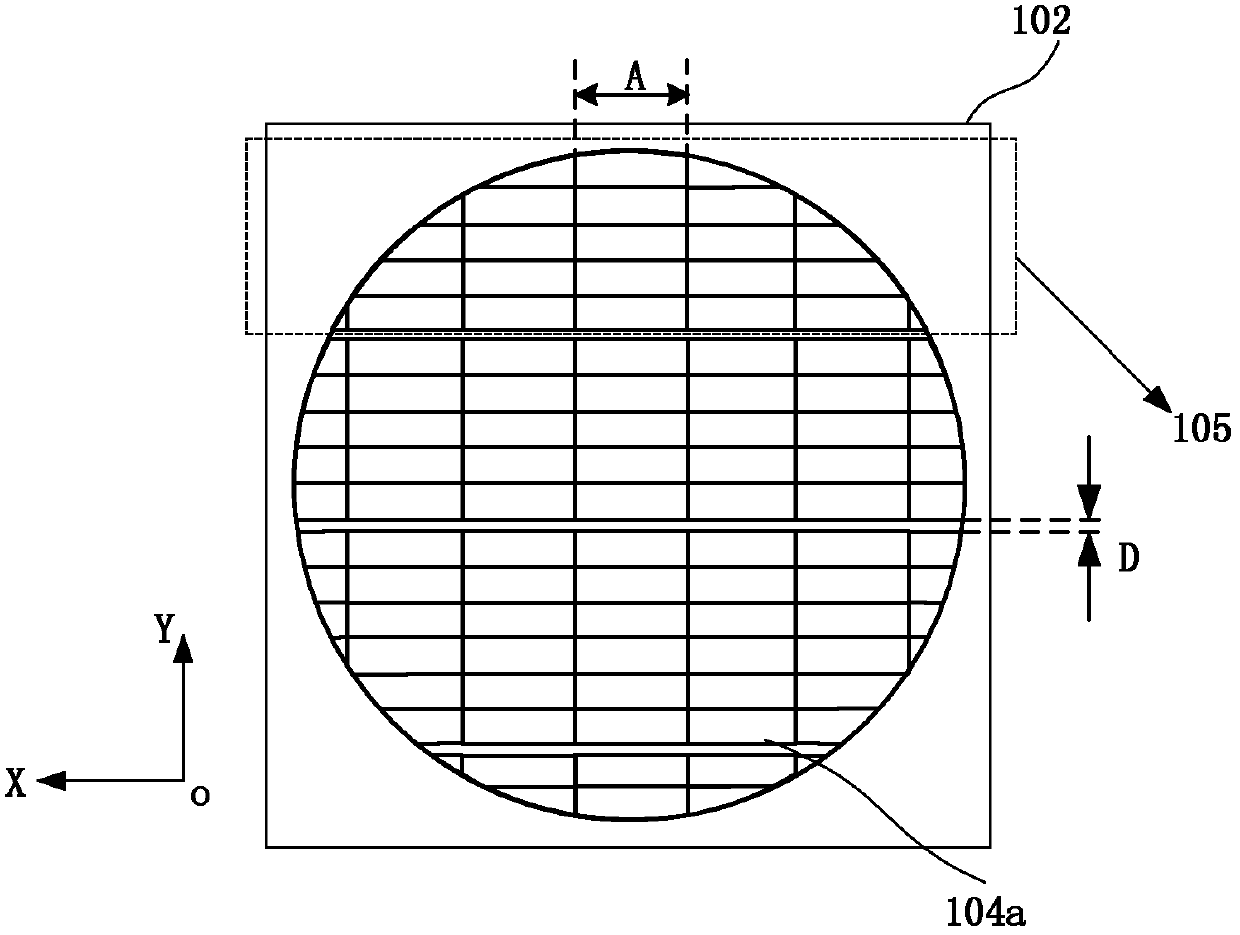

[0029] The fly-eye lens of the present invention comprises front group substrate 101, rear group substrate 102, lens unit group 105 made up of front microlens unit 103a and rear microlens unit 104a, as figure 1 As shown, both the substrate and the microlens unit are made of fused silica; the microlens unit is made by etching the substrate, and the front microlens unit 103a is arranged in an array on one side of the front group substrate 101, as shown in figure 2 As shown, all the microlens units 103a have the same shape and geometric size, and the rear microlens units 104a are arranged in an array at intervals on one side of the rear group substrate 102, as image 3 As shown, the shapes and geometric dimensions of all the front microlens units 103a are the same, and the shapes and geometric dimensions of all the rear microlens units 104a are also the same, and the convex surfaces of the front microlens units 103a and the rear microlens units 104a are placed opposite to each ot...

Embodiment 2

[0040] The structure of the fly eye lens of embodiment two is as figure 2 As shown, the figure includes a substrate 100 , a front microlens unit 103 a , a rear microlens unit 104 a and a lens unit group 105 . Calcium fluoride is used for the base of the fly-eye lens and the materials of the front and rear microlens units. In this embodiment, the front microlens unit 103a and the rear microlens unit 104a are made by etching the two sides of the same substrate 100. The structures and geometric dimensions of the front microlens unit 103a and the rear microlens unit 104a, and the adjacent lens units The calculation method of the gap D of the rear microlens units at the boundary of the group 105 and the offset of the front and rear microlenses, as well as the composition method of the lens unit group 105 are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0042] Figure 10 It is a structural schematic diagram of a fly-eye lens according to Embodiment 3 of the present invention, including a front group substrate 101, a rear group substrate 102, a front microlens unit 103a, a rear microlens unit 104a and a lens unit group 105, such as Figure 10 As shown, both the substrate and the microlens unit are made of CaF 2 Material; the front microlens unit 103a and the rear microlens unit 104a are relatively placed on the inside of the front group substrate 101 and the rear group substrate 102, the microlens unit is made by etching the substrate, and the front microlens unit 103a is arranged in an array One side of the front group base 101, such as Figure 10 As shown, all the microlens units 103a have the same shape and geometric size, and the rear microlens units 104a are arranged in an array at intervals on one side of the substrate 102, and the shapes and geometric dimensions of the rear microlens units 104a are not all the same. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com