Finned radiator for transformer

A radiator and transformer technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of large circulating resistance of transformer oil, low flow rate of transformer oil, unsatisfactory heat dissipation effect of radiator, etc., to improve heat dissipation effect, increase flow rate, easy flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

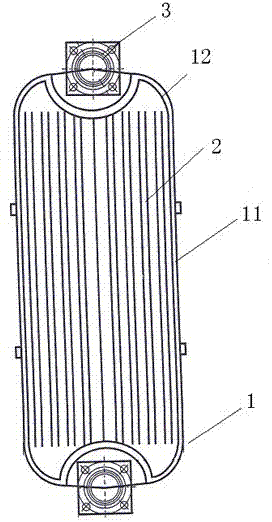

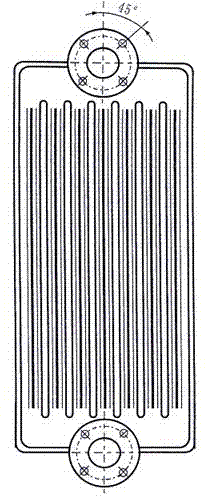

[0013] A kind of sheet radiator for transformer of the present invention, see figure 1 , the fin radiator includes an internal circulating oil passage 1, the internal circulating oil passage 1 includes straight sections 11 on both sides and curved transition sections 12 at four corners, the straight sections 11 are connected by curved transition sections 12, and the curved The transition section 12 is an arc of 200-300 mm. In the figure, 2 is a cooling fin, 3 is a connecting flange, and the connecting flange 3 is connected with the internal circulating oil 1.

[0014] The present invention improves the internal circulating oil channel of the fin radiator, filters the original small circular arc at the two ends of the single sheet, and changes the design into a large circular arc transition, which makes it easier for the transformer oil to flow in the radiator and reduces the loss of the transformer oil. Circulation flow resistance improves the flow rate of transformer oil in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com