Capacitive cross coupling flying bar and coaxial cavity resonator thereof

A cross-coupling and resonator technology, which is applied in the direction of resonators, waveguide devices, electrical components, etc., can solve the problems of large bending angle tolerance, device ignition and burnout, and increase the length of the rod, so as to achieve high installation accuracy and ensure Consistent, reliable connection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0025] 1. Capacitive cross-coupled fly rod (referred to as coupled fly rod)

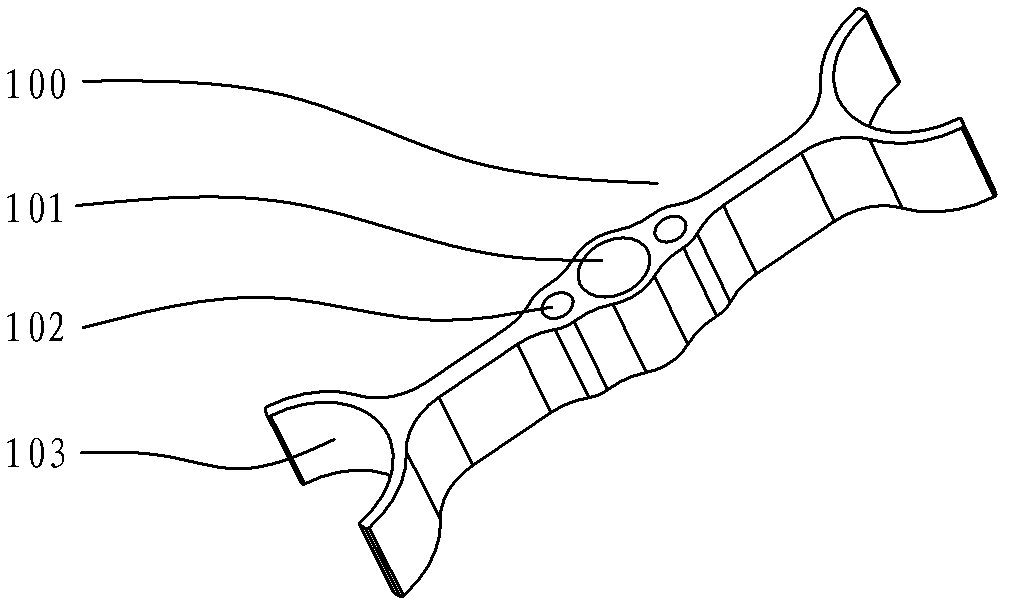

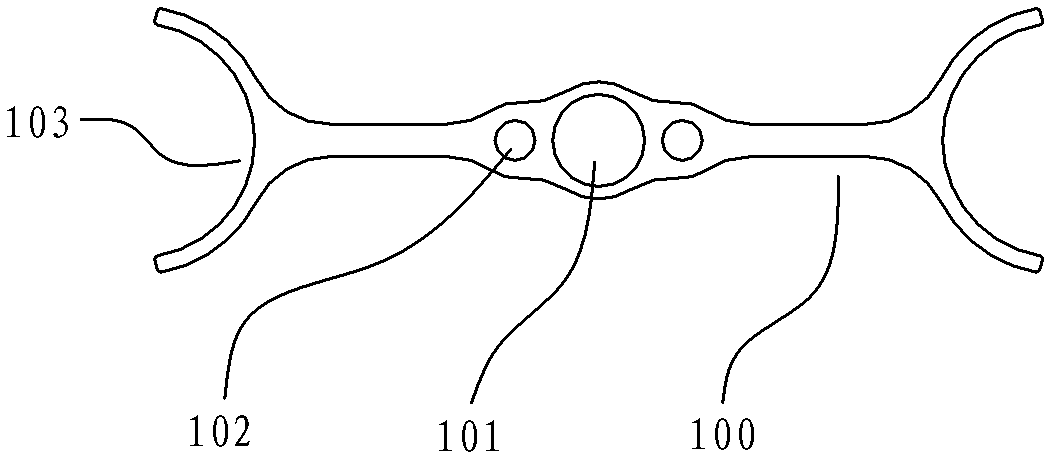

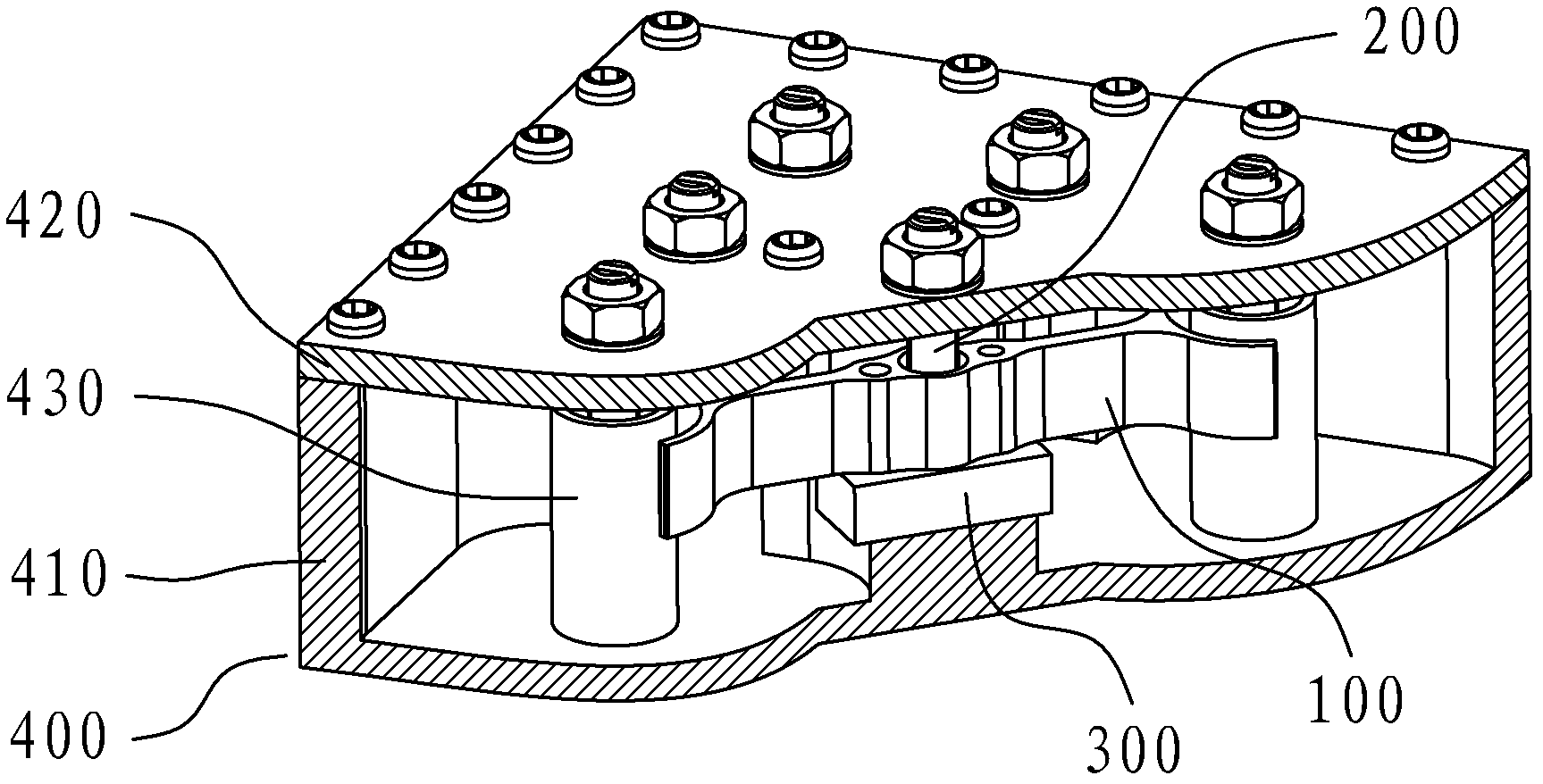

[0026] Such as figure 1 , figure 2 , the coupling flying rod 100 is a centrally symmetrical strip profile structure, the center of which is provided with a cylindrical fine-tuning coupling hole 101, and its two ends are provided with ring-shaped coupling discs 103, and in the fine-tuning coupling hole 101 Cylindrical screw fastening holes 102 are respectively provided on both sides.

[0027] The fine-tuning coupling hole 101 cooperates with the fine-tuning coupling screw 200 to adjust the cross-coupling coefficient;

[0028] The screw fastening hole 102 is connected with the insulating support body 300 with the fastening screw 110;

[0029] The coupling plate 103 cooperates with the resonant column 430 to realize cross-coupling. The coupling surface of the coupling plate 103 is an annular surface parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com