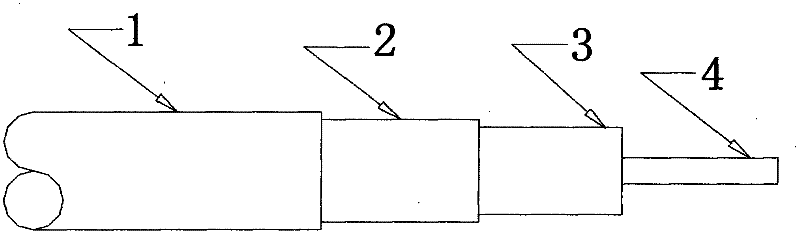

Coaxial cable stripping machine

A technology of coaxial cable and wire stripping machine, which is applied in the direction of dismantling/armouring cable equipment, etc., can solve the problems of high cost, cumulative error cannot be eliminated, parallelism and unbalanced strength, etc., and achieve low manufacturing cost and wide application range Wide range and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

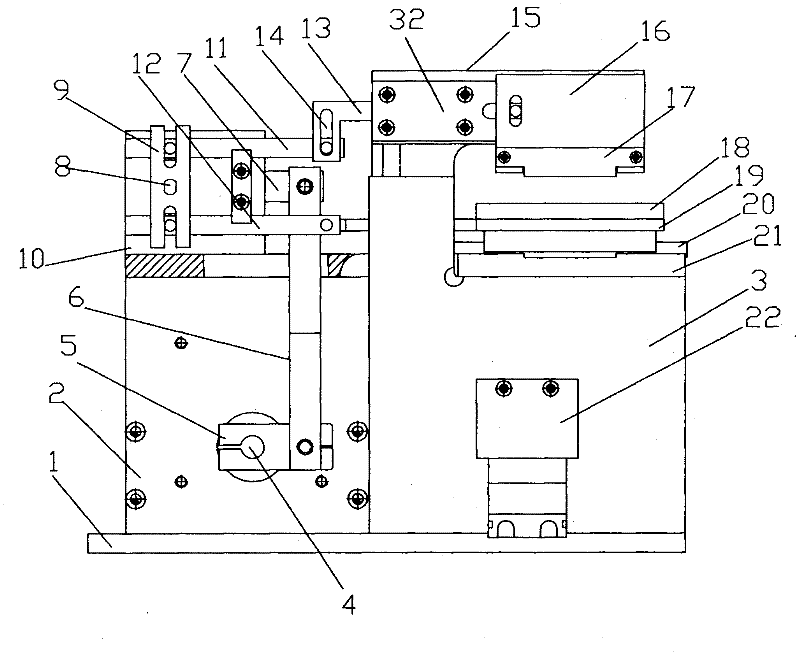

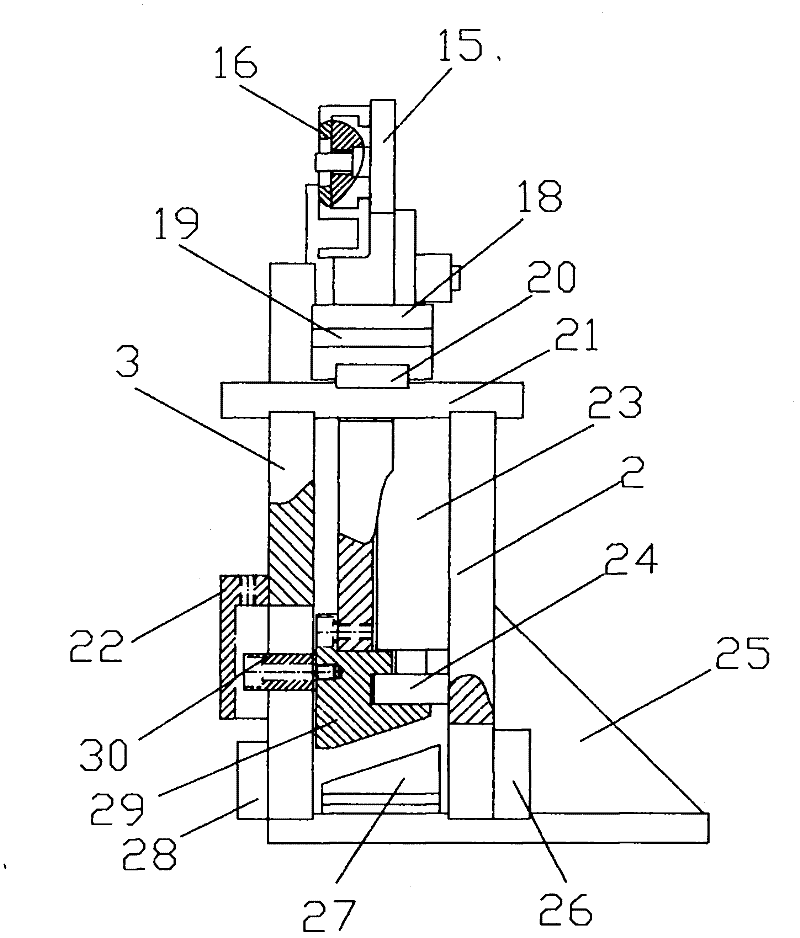

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 2 , 3 As shown, the coaxial cable stripping machine includes an upper slider 16 and a lower washboard 18, the upper slider 16 is opposite to the lower washboard 18, and the upper slider 16 is provided with a knife rest 17. Such as Figure 4 As shown, the knife rest 17 is provided with three blades 31, and the knife rest 17 is provided with three T-shaped grooves, and the three blades 31 are T-shaped and respectively stuck in the three T-shaped grooves, and the number of the blades 31 can be stripped according to the The type of wire changes, and the number of blades is generally between 1 and 4. The upper slide block 16 is also provided with a T-shaped groove, and the knife rest 17 is stuck in the T-shaped groove of the upper slide block 16 to prevent the blades from falling off. The heights of the three blades 31 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com