Resin molded article for optical element, method for manufacturing resin molded article for optical element, device for manufacturing resin molded article for optical element, and scanning optical device

A technology for resin molding and optical elements, which is applied in the field of manufacturing equipment for resin molding products for optical elements, and can solve problems such as reducing surface accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

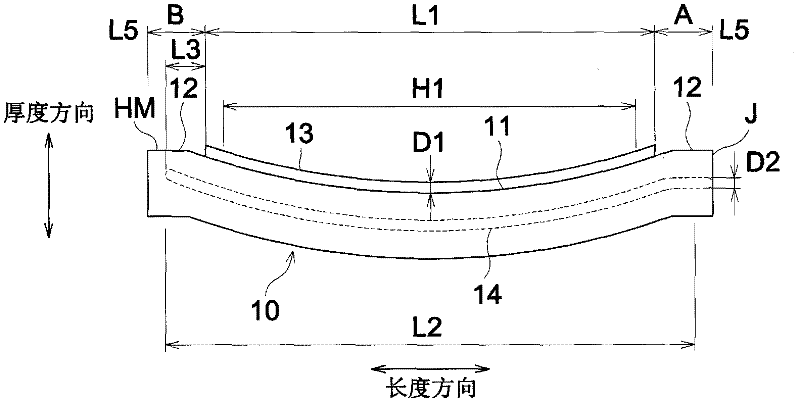

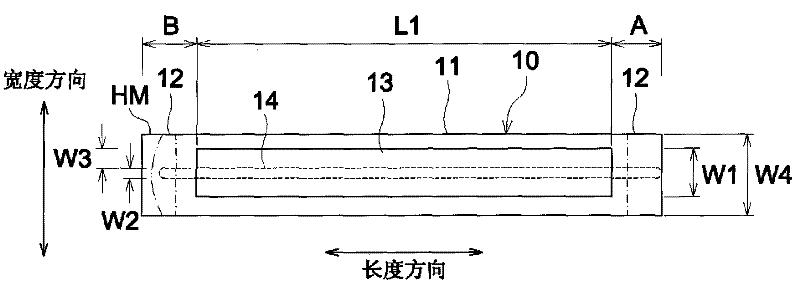

[0060] structure

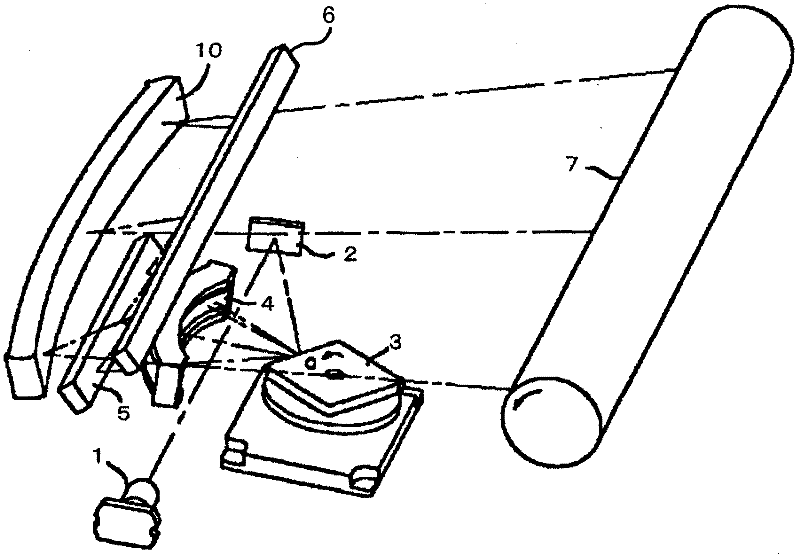

[0061] Reference figure 1 A description will be given of a resin molded product for an optical element according to the first embodiment of the present invention. figure 1 It is a schematic diagram of an example of a laser scanning optical device in which a resin molded product for optical elements is assembled.

[0062] figure 1 Among them, the laser scanning optical device includes a light source unit 1, a cylindrical mirror 2, a polygon mirror 3 as a deflection means, a Toric lens 4, plane mirrors 5 and 6, and an fθ mirror 10 with fθ characteristics.

[0063] The laser light emitted from the light source unit 1 is condensed into a substantially parallel light by a collimator lens (not shown in the figure), and then is reflected by the cylindrical mirror 2, and its beam shape is changed to a substantially linear shape with the longitudinal direction parallel to the main scanning direction , Reach the polygon mirror 3.

[0064] The outer peripheral surface of the ...

no. 2 Embodiment approach

[0146] Next reference Figure 13 , Figure 14 A description will be given of the resin molded product for an optical element according to the second embodiment of the present invention. Figure 13 It is a plan view of a resin molded product for optical components, Figure 14 This is a cross-sectional view of a resin molded product for optical elements. Regarding the resin molded product for optical elements of the first embodiment described above, the fθ mirror 10 is representatively described, and the resin molded product for optical elements of the second embodiment is representatively described fθ lens 20.

[0147] The fθ lens 20 is provided in the laser scanning optical device like the fθ mirror 10. The fθ mirror 10 has a mirror surface 13 that reflects laser light, while the fθ lens 20 has an optical surface 23 that transmits laser light. The fθ lens 20 having the optical surface 23 also has the same function as the fθ mirror 10, and converts the speed of laser light deflect...

Embodiment

[0168] Hereinafter, the present invention will be explained based on preferred embodiments. The resin molded product manufactured in the example is the base material of the fθ mirror 10. The comparative example is also the base material of the fθ mirror 10.

[0169] Using the above manufacturing device and manufacturing method, the cavity shape is image 3 The type shown is molded and manufactured with the following two types of molds.

[0170] Type 1

[0171] A=B=5.0mm

[0172] Of the two fθ mirrors obtained by evaluation and molding, both of them confirmed that the shape deterioration caused by sinking or the like on the entire first surface portion was suppressed, and a mirror shape with high surface accuracy was obtained.

[0173] In addition, by using this mirror in a scanning optical device using laser light with a wavelength of 408 nm, it was confirmed that the spots were highly concentrated and high-definition image formation was possible.

[0174] Type 2

[0175] As a compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com