Drive device and vehicle with same

A driving device and drive shaft technology, which is applied in the transmission device, power device, electric power device, etc., can solve the problems of large oil viscosity resistance, inability to independently control the left and right wheels, and the large number of components of the driving device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

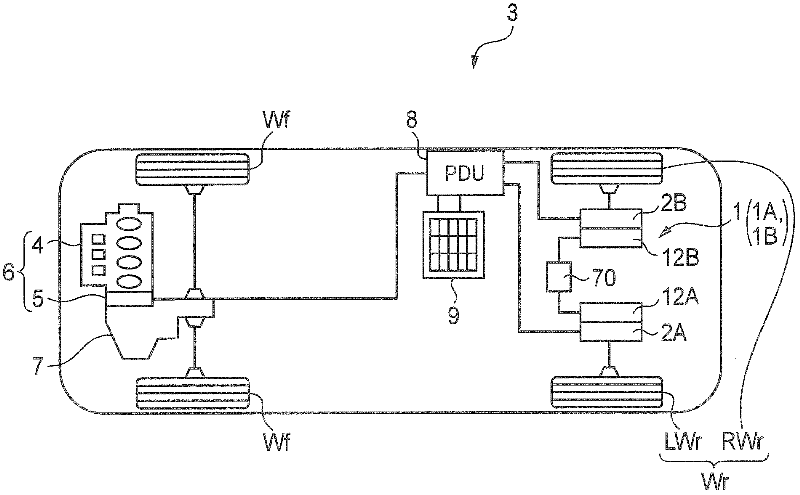

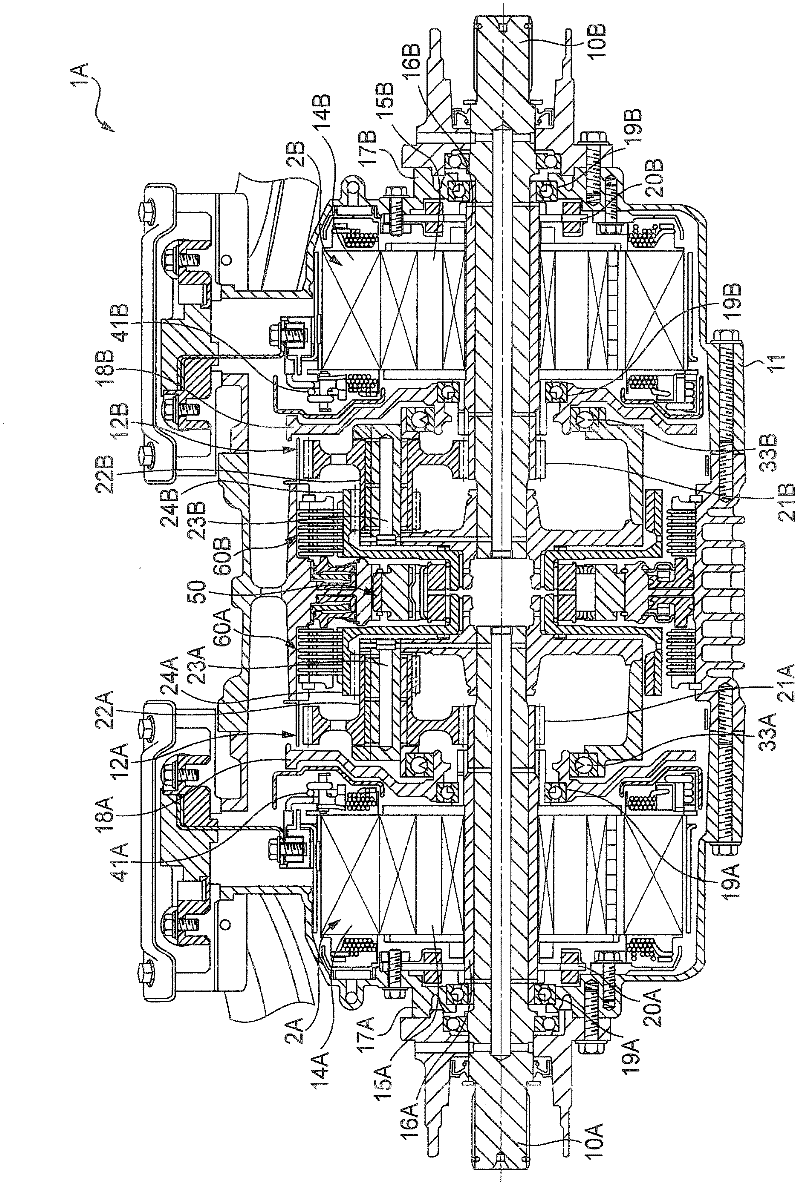

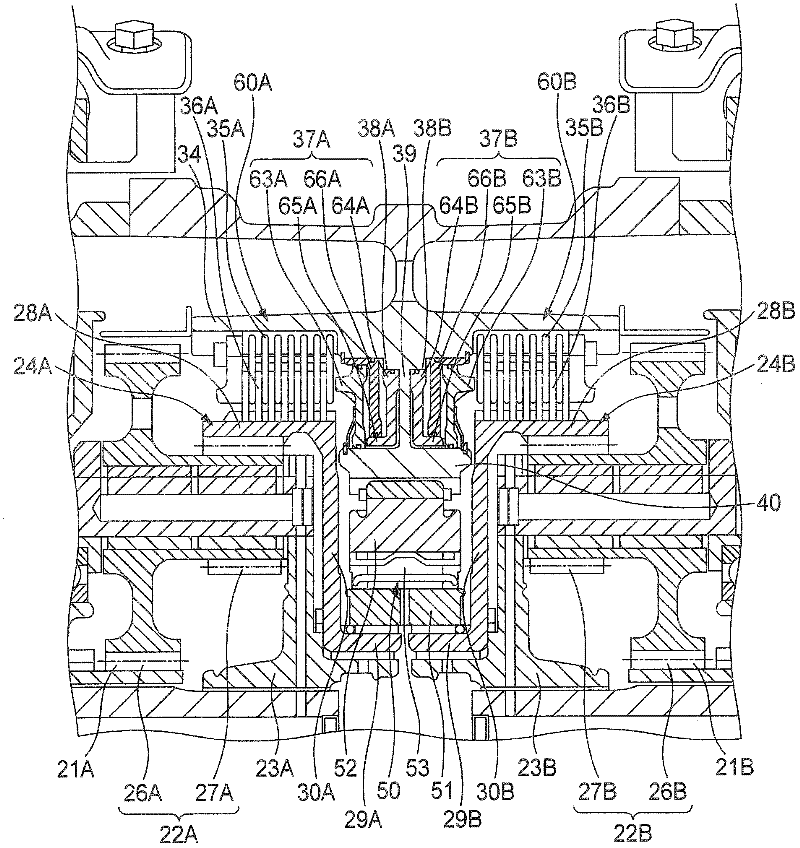

[0133] figure 2 It is a longitudinal cross-sectional view showing the whole of the driving device 1A according to the first embodiment. In this figure, 10A and 10B denote left and right axles on the rear wheel Wr side of the vehicle, and are coaxially arranged in the vehicle width direction. The speed reducer housing 11 of the driving device 1A is formed in a substantially cylindrical shape as a whole, and the motors 2A and 2B for driving the axles and the planetary gear speed reducers 12A and 12B for reducing the driving rotation of the motors 2A and 2B are arranged inside the speed reducer case 11. On the same axis as the axles 10A, 10B. The electric motor 2A and the planetary gear reducer 12A control the left rear wheel LWr, the electric motor 2B and the planetary gear reducer 12B control the right rear wheel RWr, and the electric motor 2A, the planetary gear reducer 12A, the electric motor 2B and the planetary gear The type speed reducer 12B is arranged in the speed redu...

no. 2 approach

[0145] Next refer to Figure 4 and Figure 5 A drive device according to a second embodiment of the present invention will be described. It should be noted that the driving device of the second embodiment has the same structure except for the arrangement of the driving device 1A, the hydraulic brake, and the one-way clutch of the first embodiment, so the same or equivalent parts are given the same or equivalent symbols. , and its description is omitted.

[0146] Figure 4 10A, 10B are left and right axles on the rear wheel Wr side of the vehicle, and are coaxially arranged in the vehicle width direction. The speed reducer housing 11 of the driving device 1B is formed in a substantially cylindrical shape as a whole, and the motors 2A and 2B for driving the axles and the planetary gear speed reducers 12A and 12B for reducing the driving rotation of the motors 2A and 2B are arranged inside. On the same axis as the axles 10A, 10B. The electric motor 2A and the planetary gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com