Three-component standard vibration table based on lock type decoupling device

A decoupling device and three-component technology, which is applied in the field of three-component standard shaking tables, can solve the problems of complex data processing, time-consuming, and difficulty in obtaining sensitivity matrices, achieve good decoupling effects, solve three-component motion decoupling, and avoid interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

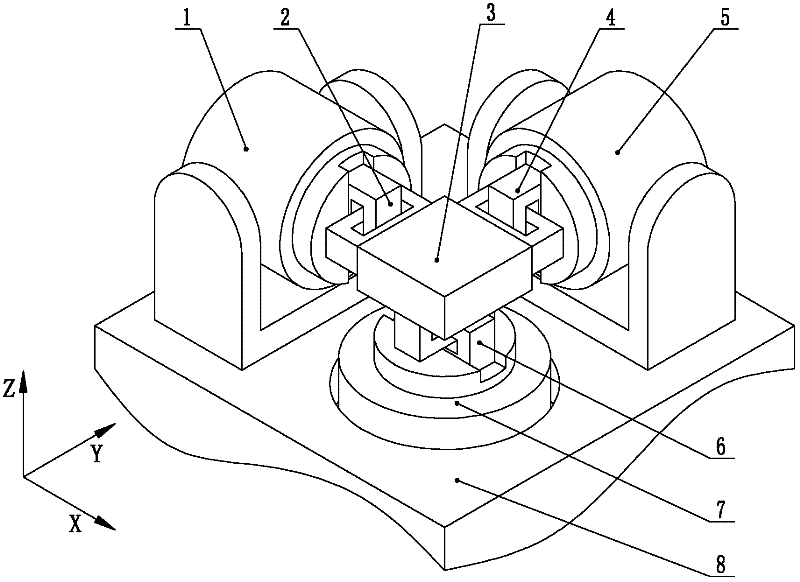

[0022] refer to Figure 1-4

[0023] The three-component standard vibration table based on the locking decoupling device includes a base 8, and the base is provided with an X-direction electromagnetic vibration table 1 that vibrates along the X-axis, and a Y-direction electromagnetic vibration table 5 that vibrates along the Y-axis , a Z-direction electromagnetic vibrating table 7 vibrating along the Z-axis, and a three-dimensional vibrating platform 3 connected with three electromagnetic vibrating tables 1, 5, and 7; each electromagnetic vibrating table passes through a motion decoupling device 2 corresponding to the vibrating table , 4, 6 are connected with the three-dimensional vibration platform 3;

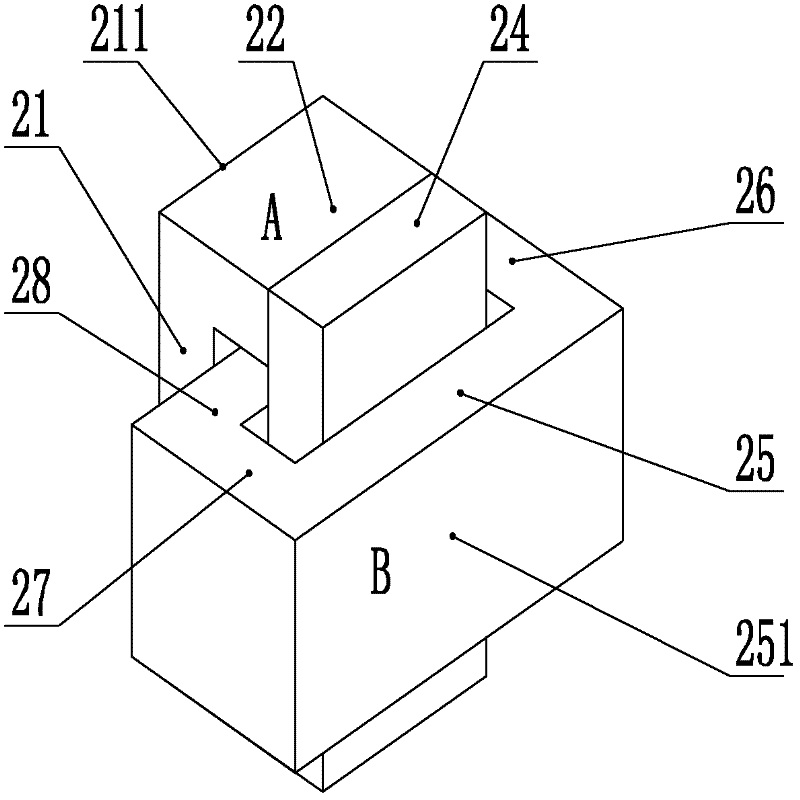

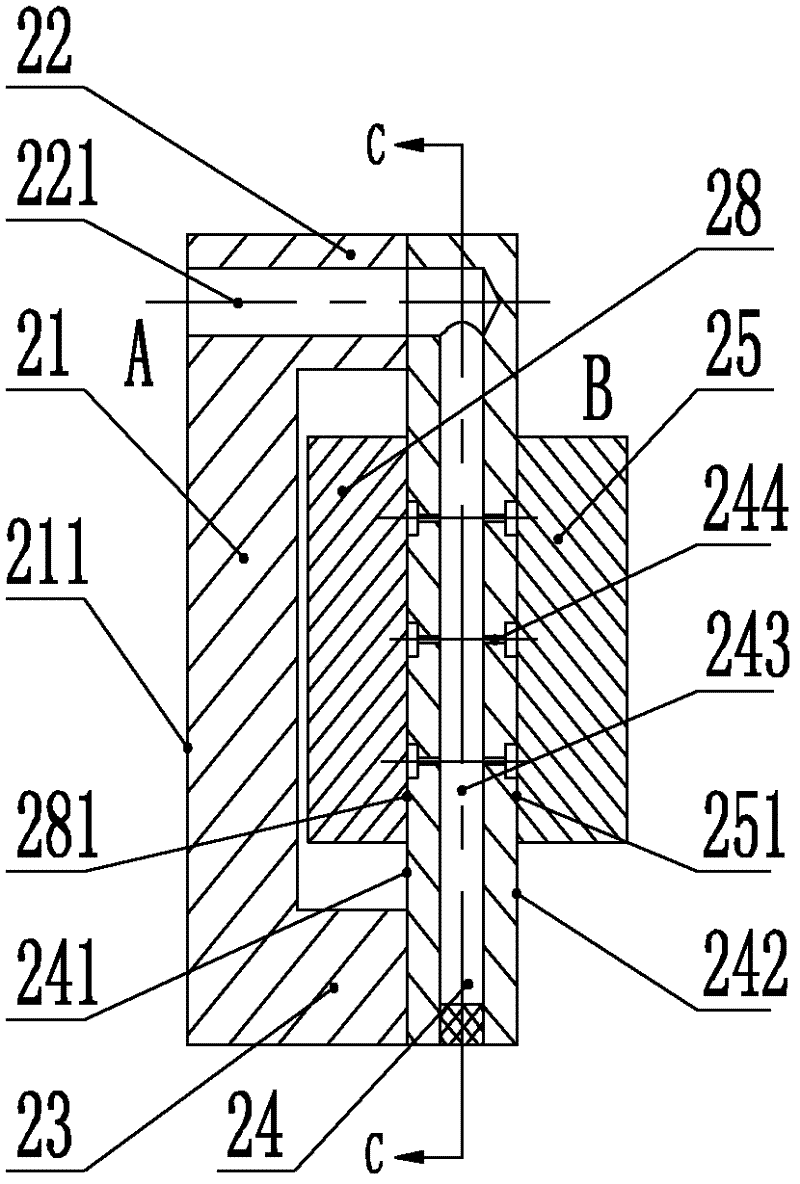

[0024] The motion decoupling device includes a first frame A and a second frame B made of rigid materials, the first frame A and the second frame B are interlocked, and the first frame and the second frame are both made of outer edges , the inner edge, the first connecting s...

Embodiment 2

[0035] The difference between the present embodiment and the first embodiment is that: one end of the airflow channel is sealed, and the other end is connected to the external compressed air source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com