Manufacturing method based on control over angle of contact hole wall of liquid crystal display device

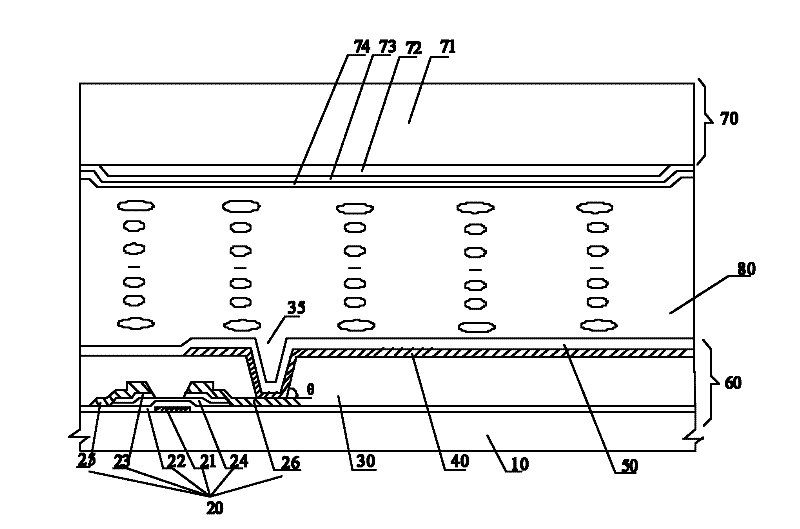

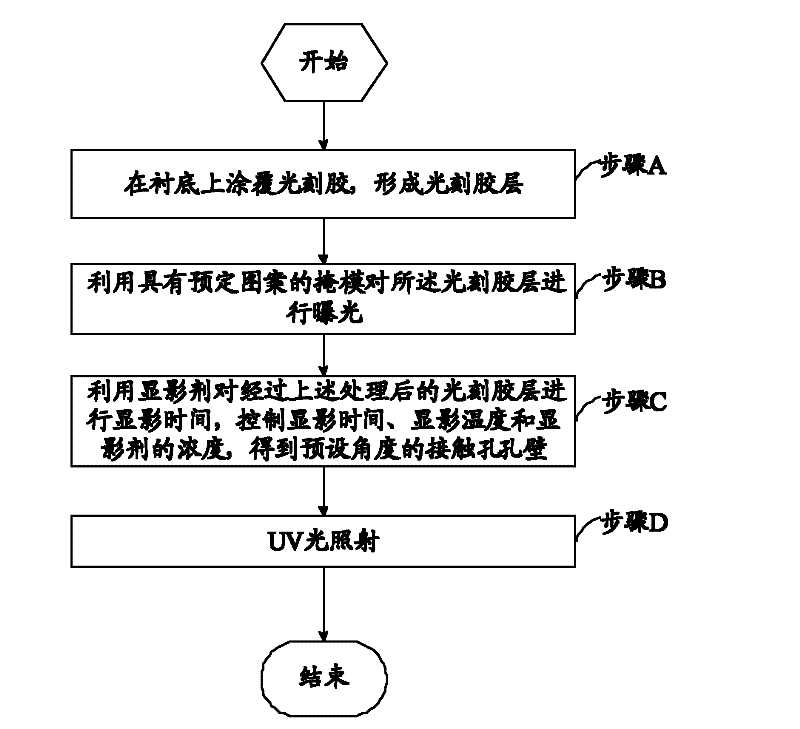

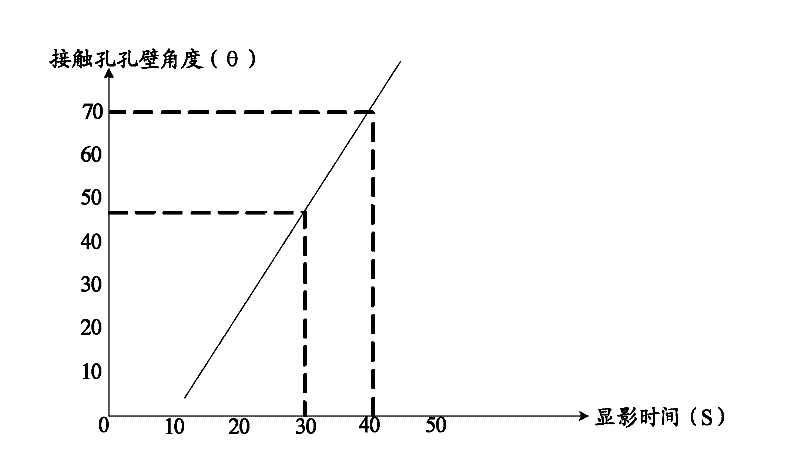

A technology of a liquid crystal display device and a manufacturing method is applied in the field of manufacturing the angle of the wall of the contact hole of the liquid crystal display device, and can solve the problems of inability to accurately control the angle of the contact hole 35, the area is too large, and the aperture ratio is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0038] As we all know, photoresist is a photosensitive material temporarily coated on the wafer, similar to the photosensitive material of the negative film, and a chemical reaction occurs after being irradiated, thereby transferring the optical pattern on the photomask to the wafer surface. In the process of forming the contact hole pattern, a positive photoresist is generally used due to its high resolution requirements. This type of photoresist is usually a phenolic resin (Novolac) crosslinked by a photosensitive agent. When exposed to light, photons trigger the photosensitive acid generator (PAG) in the photoresist to undergo a photochemical reaction to generate protons H + (photoacid), this proton will react with the photoresist to cause its relationship bond to be broken and decrosslinked, so that the exposed p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com