Electro-hydraulic control system server chasis of thin-seam hydraulic support

An electro-hydraulic control system, hydraulic support technology, applied in the direction of chassis/cabinet/drawer parts, electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problem of small support space, limited installation location, production efficiency Low problems, to achieve the effect of firm connection, excellent sealing performance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

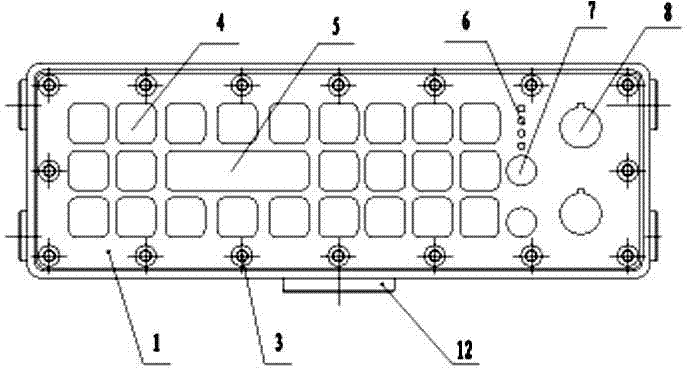

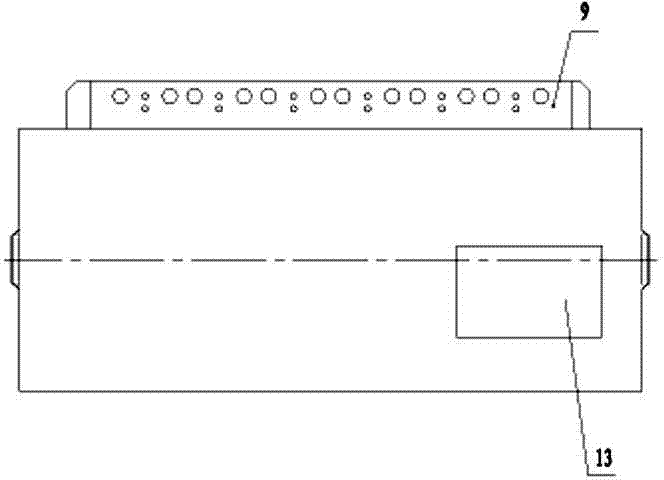

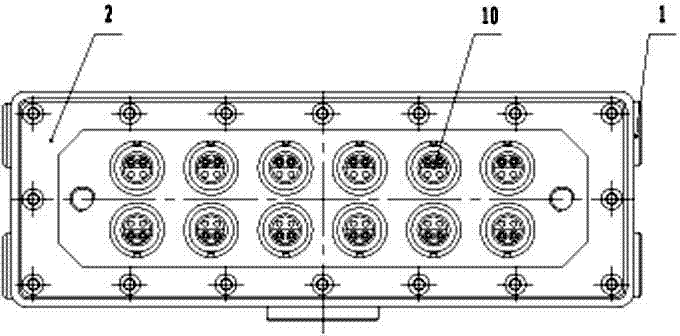

[0013] Such as figure 1 , 2 , 3, the thin coal seam hydraulic support electro-hydraulic control system server casing of the present invention includes a frame structure surrounded by upper, lower, left and right side panels and front and rear panels coated on the outside of the server The shell, the upper, lower, left and right side plates of the shell are an integrated structure made of stainless steel, the stainless steel front panel 1 and the rear panel 2 are sealed with the upper, lower, left and right side plates through the through screws 3 arranged evenly around the periphery They are fixed together, and sealing gaskets are respectively arranged on the joint surfaces between the front panel 1, the rear panel 2 and the side panels; the front panel 1 is provided with key openings 4, display windows 5, indicator light openings 6, infrared receiving The window 7 and the button installation port 8, the display window 5 is set in the middle of the front panel 1, and the key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com