Cleaning device

A cleaner and cleaning technology, applied in the field of cleaners, can solve problems such as inability to manually operate, and achieve the effects of simplified cleaning, fast and safe manual cleaning, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

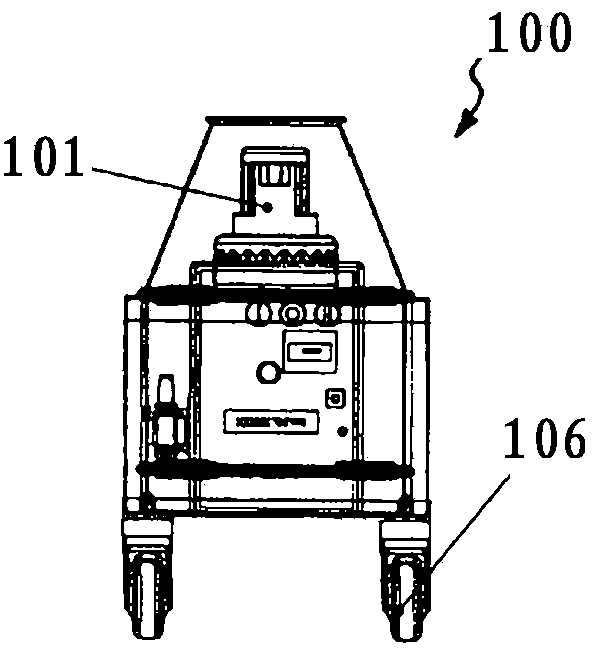

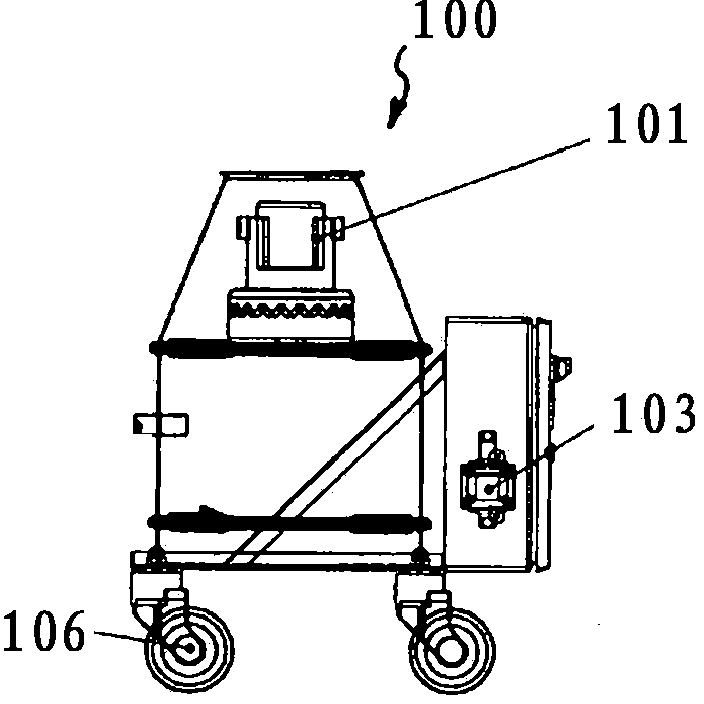

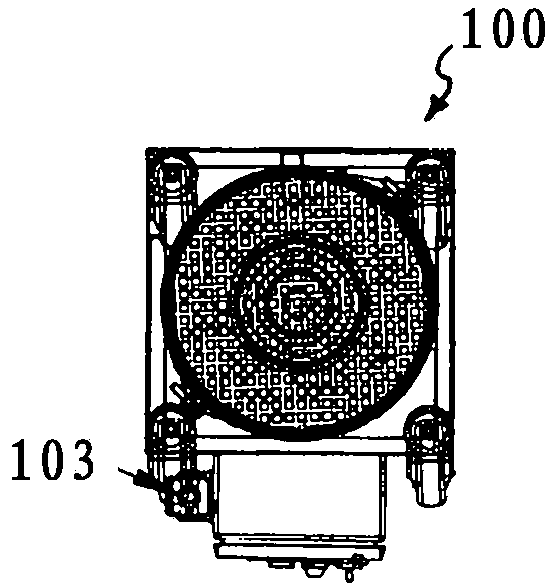

[0039] exist Figures 1 to 6 shows assemblies of cleaners for cleaning flat and curved surfaces and in particular for cleaning printing rollers, printing cylinders, blanket printing cylinders and other cylindrical circular bodies. The cleaner has a mountable operating unit 1 . exist figure 1 with 2 The handling unit 1 shown in detail in has a continuous cleaning belt 3 which can be rotatably driven and steered around two steering devices 2, 2' by means of a drive motor. One of the two deflectors is configured as a rod-shaped, torsionally fixed deflector 2', the other deflector 2 is configured as a rotary roller in drive connection with the drive motor. The steering devices 2, 2' are arranged in the handling unit 1 axially parallel to each other. In order to be able to tension the cleaning belt 3 between the deflectors 2, 2', the bar-shaped deflector 2' is provided with a tensioning device 20. By means of the tensioning device 20 the distance between the deflectors 2 , 2 ′...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com