Processing method of aluminum-free wet vermicelli

A processing method and wet powder technology, applied in the processing field of aluminum-free wet noodles, can solve problems such as aggregation of aluminum components, and achieve the effects of chewy, good viscoelasticity and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

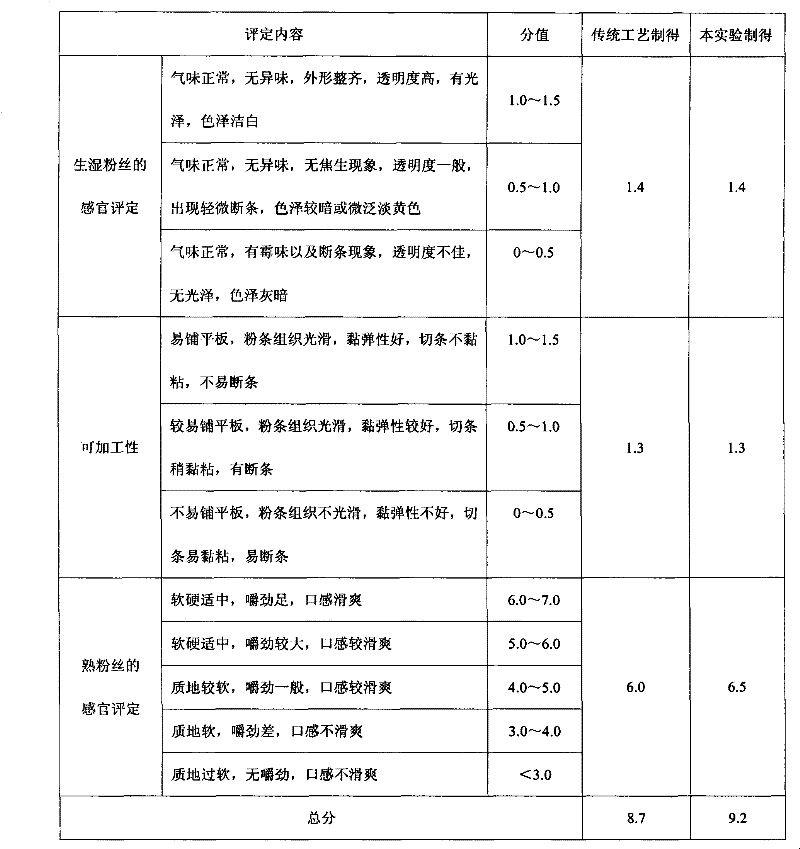

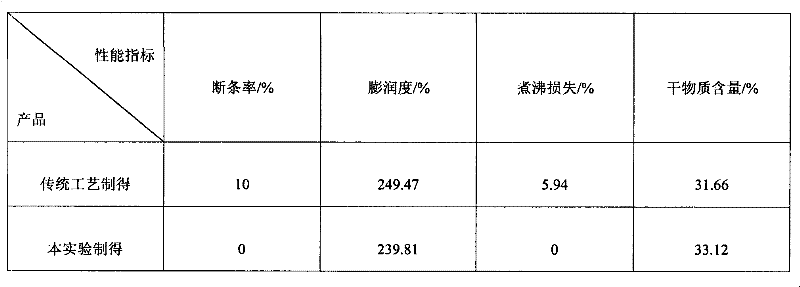

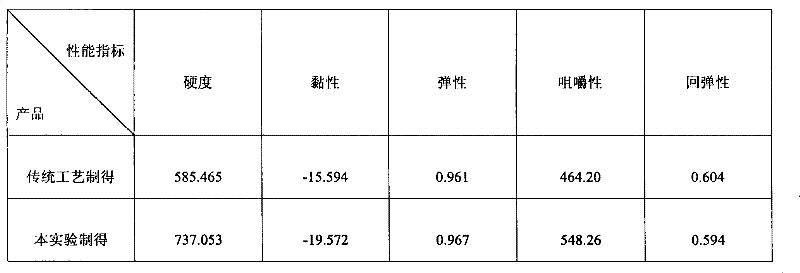

Examples

Embodiment 1

[0014] (1) Raw material ratio: mix potato starch, tapioca starch, and corn starch according to the weight ratio of 3:4:3 as raw material starch.

[0015] (2) Thickening starch: starchy starch is potato starch, and the weight ratio of starchy starch and starch obtained in step 1 is 1:10. Mix starchy starch and water in a weight ratio of 1:1 and stir evenly; then add Hot water at about 80°C with 2 times the mass of Gorgon powder, fully stirred until a transparent colloid (Gorgon ball) appears.

[0016] (3) Kneading dough: add 0.20% soda ash, 2.00% salt, and 1.00% konjac gum accounting for the total weight of the starch obtained in step (1), fully mix with the raw material starch and the obtained Gorgon mass of step (2), and add water to The total amount of water added accounts for 70% (percentage by weight) of the proportion of raw starch. Knead the dough for about 10 minutes to make the starch dough even and soft.

[0017] (4) Extrusion and ripening: After the above-mentioned...

Embodiment 2

[0027] (1) Raw material ratio: mix potato starch, tapioca starch, and corn starch according to the weight ratio of 3:4:3 as raw material starch.

[0028] (2) Thickening starch: starchy starch is potato starch, and the weight ratio of starchy starch and starch obtained in step 1 is 1:10. Mix starchy starch and water in a weight ratio of 1:1 and stir evenly; then add Hot water at about 80°C with 2 times the mass of Gorgon powder, fully stirred until a transparent colloid (Gorgon ball) appears.

[0029] (3) Kneading: Adding 0.20% soda ash, 2.00% salt, 1.00% konjac gum and 0.25% sodium carboxymethyl cellulose, fully mixed with raw material starch and step (2) ) the obtained gorgon dough is mixed evenly, and water is added until the total amount of water added accounts for 70% (percentage by weight) of the ratio of raw starch. Knead the dough for about 10 minutes to make the starch dough even and soft.

[0030] (4) Extrusion and ripening: After the above-mentioned kneaded dough i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com