Cutter driving device in gear processing machine

A driving device and processing machine technology, applied in the direction of gear tooth manufacturing device, driving device, metal processing machinery parts, etc., can solve the problems of reducing the rotation speed of the main shaft, poor mechanical stability, and incompatibility of the main shaft structure, and achieves improved processing. Accuracy and efficiency, reliable high-speed rotation, safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

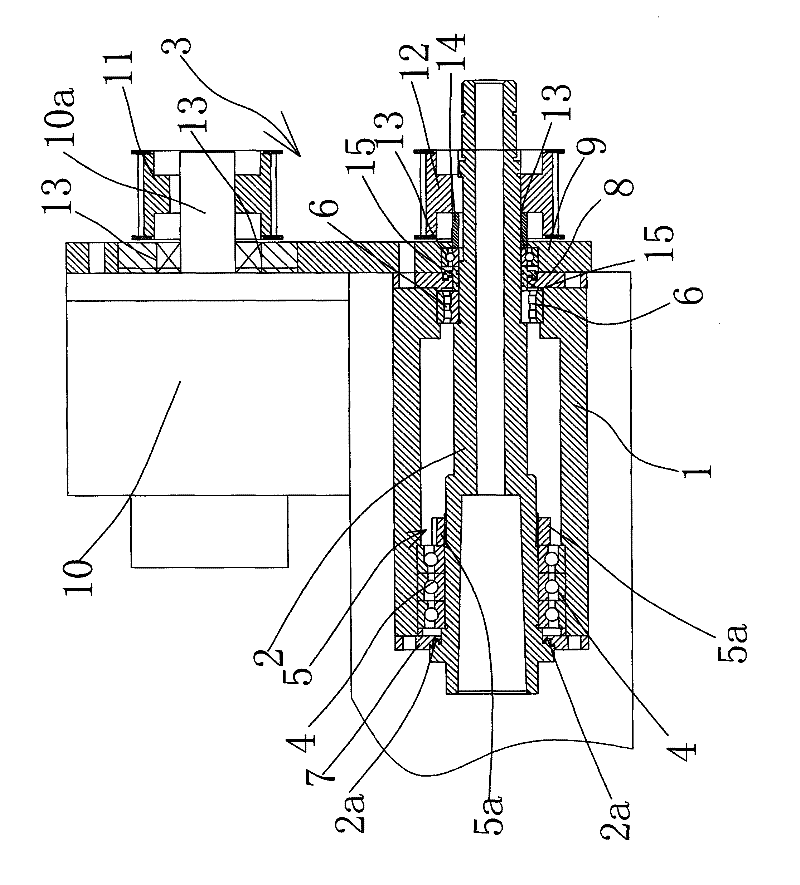

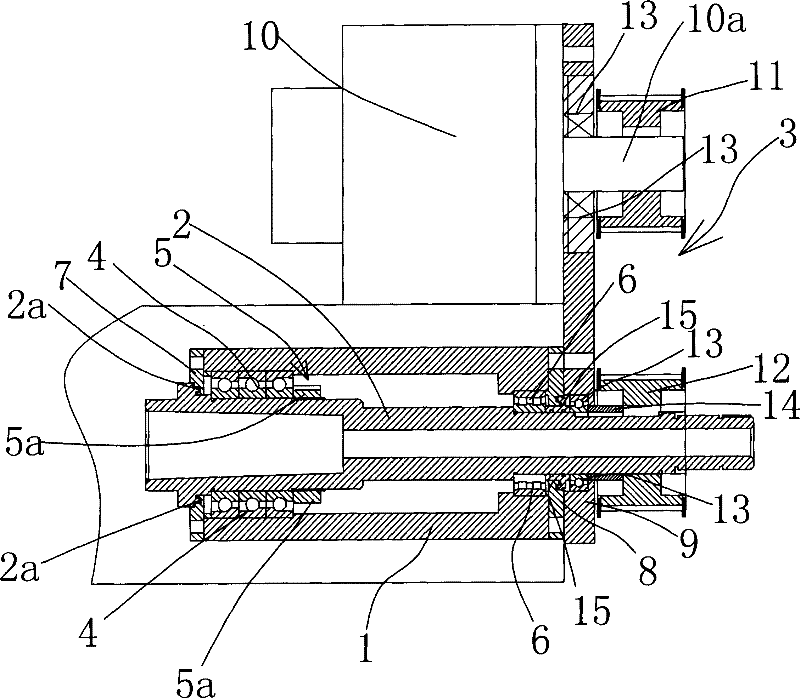

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0018] In the figure, tool holder 1; main shaft 2; step surface 2a; driving mechanism 3; angular contact bearing 4; adjustment member 5; lock nut 5a; cylindrical roller bearing 6; left bearing end cover 7; right bearing end cover 8; Fixed plate 9; motor 10; motor shaft 10a; upper pulley 11; lower pulley 12; centripetal ball bearing 13; adjustment sleeve 14;

[0019] Such as figure 1 As shown, the tool driving device in this gear processing machine includes a tool seat 1, a main shaft 2 and a driving mechanism 3, the main shaft 2 is arranged in the tool seat 1, and a left bearing end is arranged between the front end of the tool seat 1 and the main shaft 2 The cover 7 is provided with a right bearing end cover 8 between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com