Continuous automatic line conveying equipment unit capable of synchronously and medially clamping

A technology of conveying equipment and automatic lines, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of high manufacturing cost, low transmission efficiency, poor operation stability, etc., and achieve the effect of solving pause and rigid impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

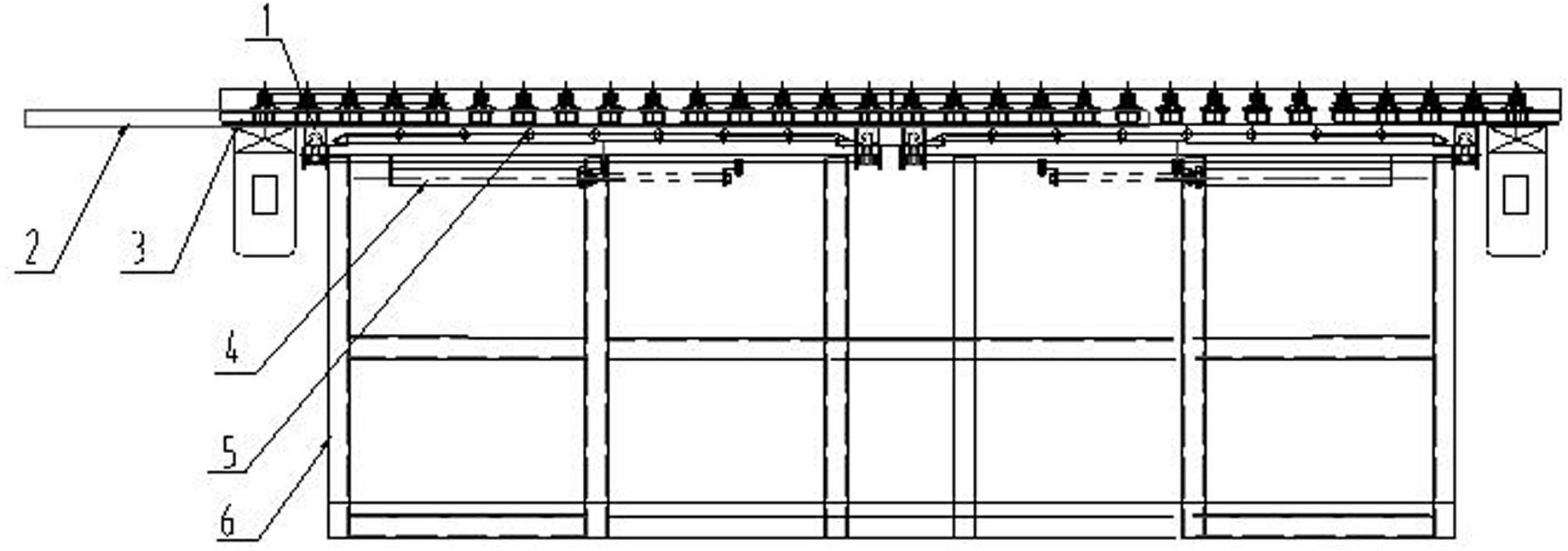

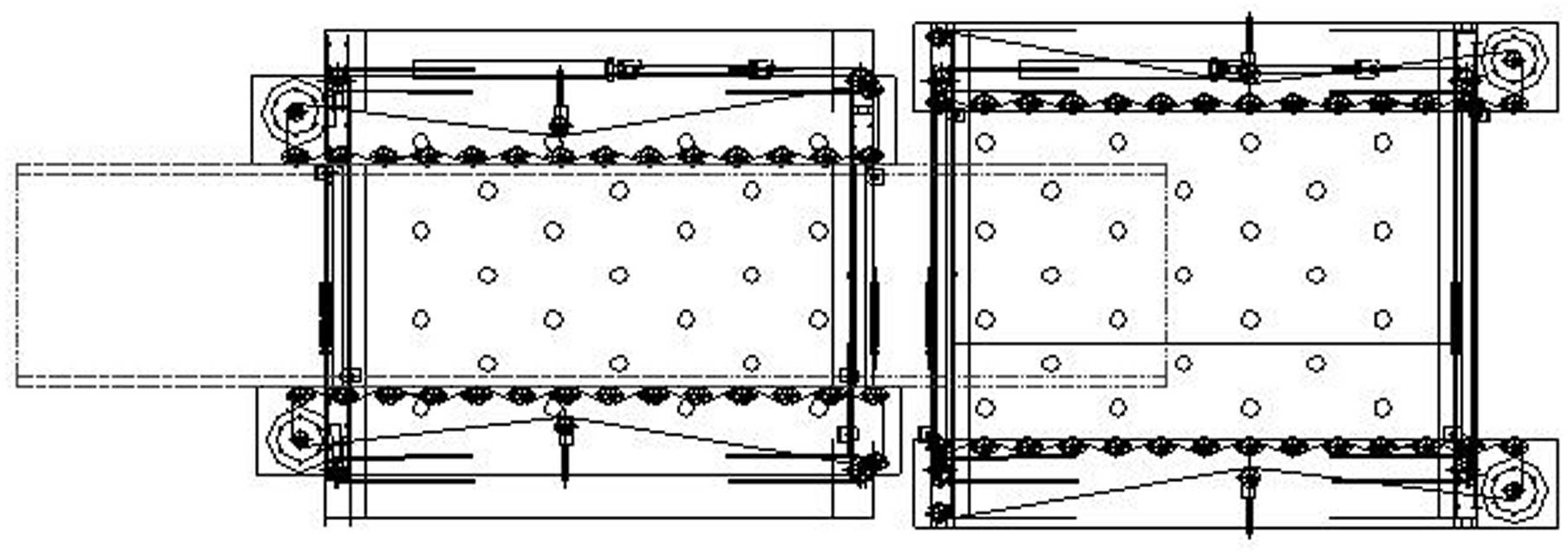

[0023] Example 1 as Figure 1 to Figure 9 shown. Wherein, the overall structure of embodiment 1 is as follows figure 1 , figure 2 shown. The synchronous centering clamping continuous transmission equipment unit of the present invention is composed of a slider assembly 1 , a product diagram 2 , a linear transmission mechanism 3 , a synchronous centering clamping mechanism 4 , a working surface 5 , and a fixed bracket 6 . Work surface 5 is the work surface with universal ball. The invention is suitable for processing the following materials: stainless steel, color-coated plates and oil-free cold-rolled steel plates, sheet metal parts with a plate thickness less than or equal to 2.0 mm. The invention provides the function of automatically synchronously centering the product and continuously conveying the workpiece at high speed, and performs the start and stop function according to the process requirements, and cooperates with the process to automatically complete the necess...

Embodiment 2

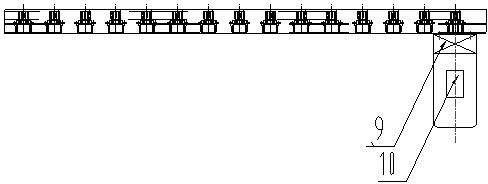

[0029] The center clamping structure of embodiment 2 is as Figure 10 to Figure 12 As shown, it is a centered clamping structure of 3 sets of sliders. The difference from Embodiment 1 is that Embodiment 1 is a transmission device with one group of power and one synchronous centering clamping mechanism, and Embodiment 2 is a transmission device with multiple groups of power and multiple synchronous centering clamping mechanisms. 2 steel wire wheels and 2 steel wires have been added in embodiment 2, but structure and mode of operation are the same as Figure 7 to Figure 9 Same as in the implementation shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com