Rotating spray arm for dish-washing machine

A technology of rotating spray arms and dishwashers, which is applied in the direction of tableware washing machines/rinsing and washing machine parts, etc., and can solve the problem of uneven mist water and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

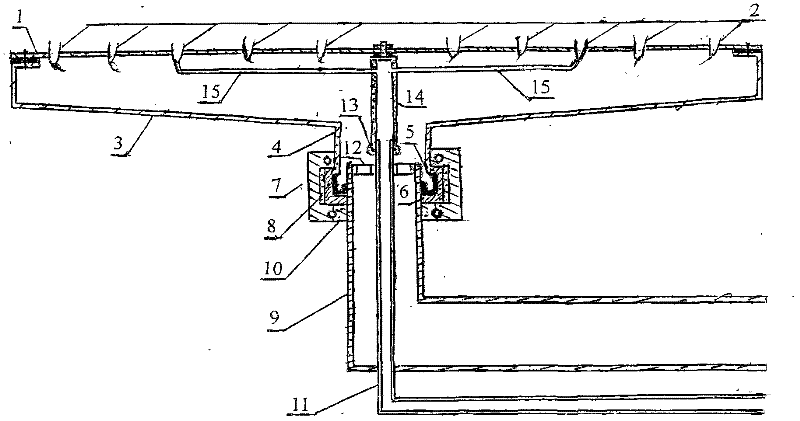

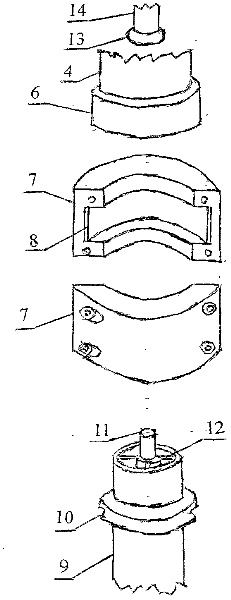

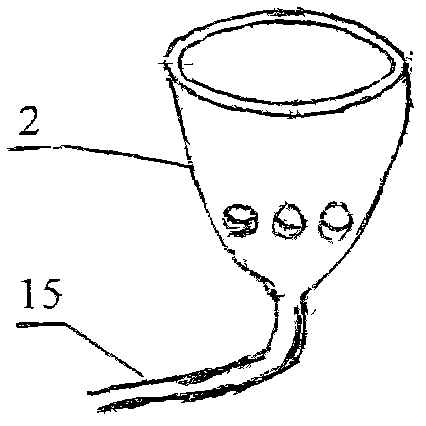

[0011] figure 1 , figure 2 , image 3 As shown, the rotary spray arm of the dishwasher of the present invention includes: a cover 1, a conical nozzle 2, a water tank 3, an upper water pipe 4, a water sealing ring 5, a hollow rotating shaft 6, a bearing seat 7, a copper bearing bush 8, and a water inlet pipe 9 , flange 10 and intake pipe 11. The lid 1 is equipped with many conical nozzles 2 protruding from the bottom of the lid 1 and opening obliquely upwards; the side of the conical nozzle 2 part under the lid 1 has many small holes. The lower edge of the lid 1 has a circle of gaskets as the seal between the lid 1 and the water tank 3, and the lid 1 is fixed on the water tank 3 with screws. The central position below the water tank 3 is connected with the upper water pipe 4. The following of the upper water pipe 4 is connected with a hollow rotating shaft 6 whose external diameter is greater than the upper water pipe 4, the hollow rotating shaft 6 lower end has a shrinkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com