Bolt cold header, mould box thereof and correcting and adjusting method for positioning mould

A cold heading machine and mold box technology, applied to bolts, manufacturing tools, threaded fasteners, etc., can solve problems such as mold box instability, long transposition time, errors, etc., achieve good product quality and accuracy, and shorten the length of the crankshaft , the effect of shortening the length of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

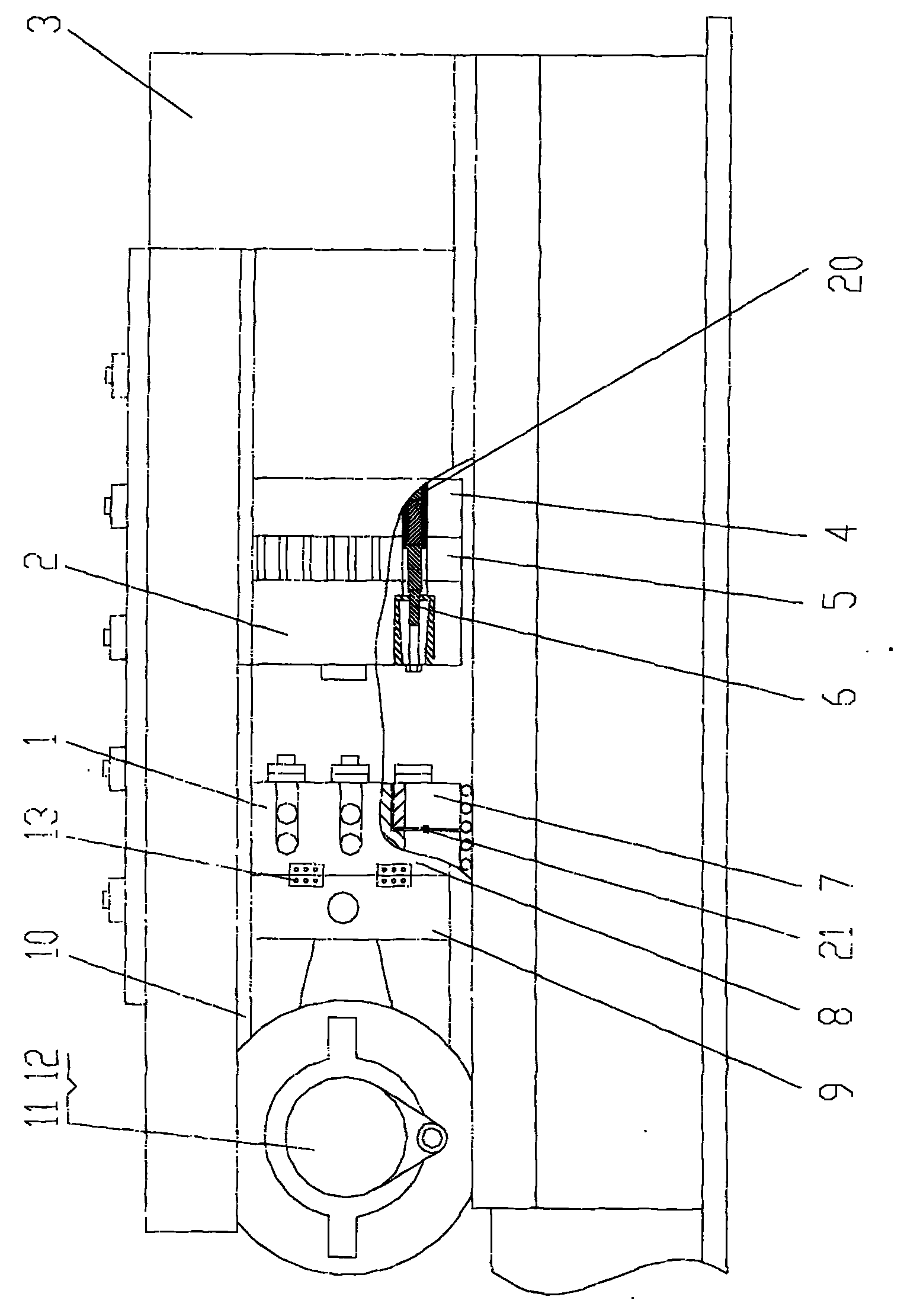

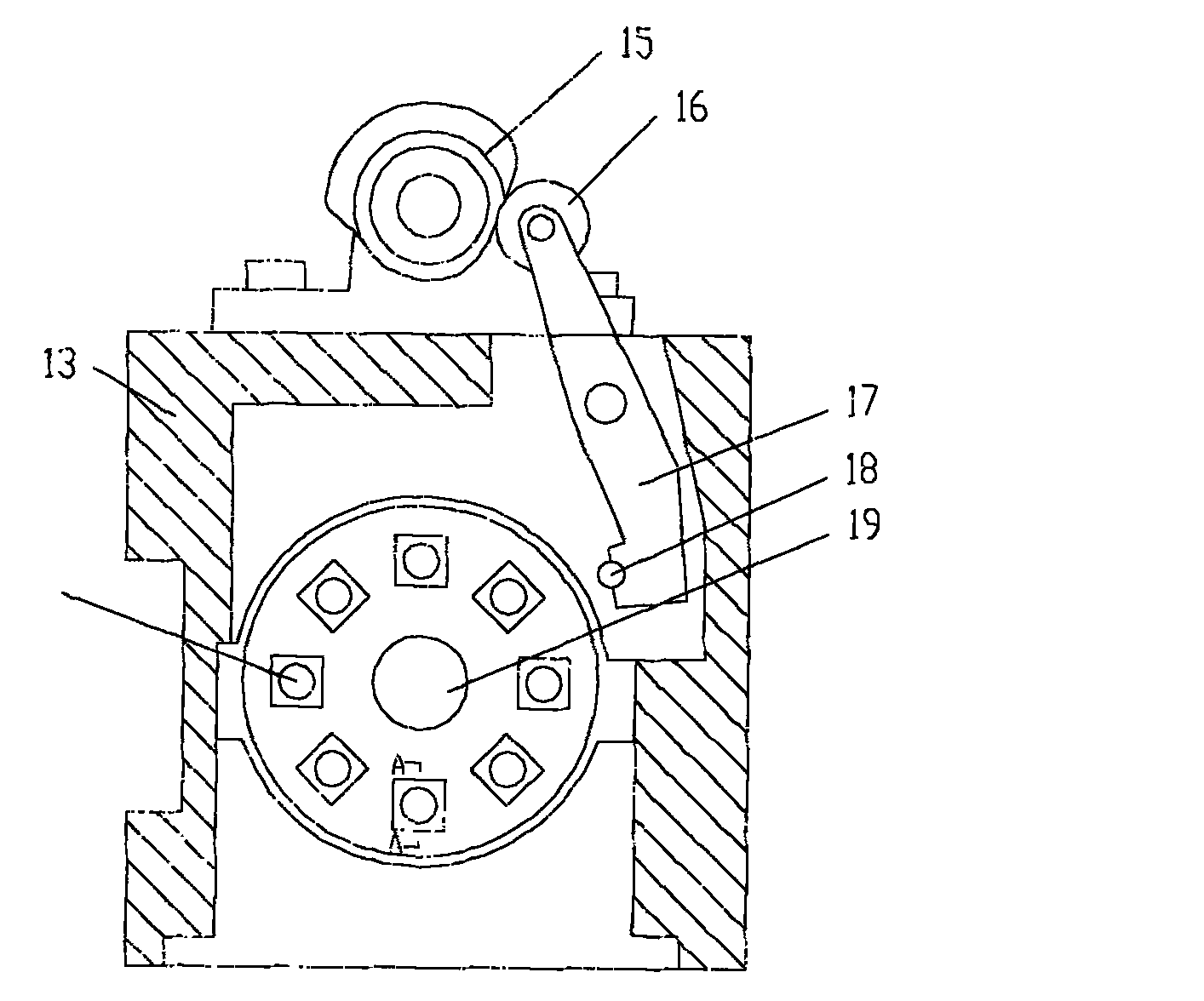

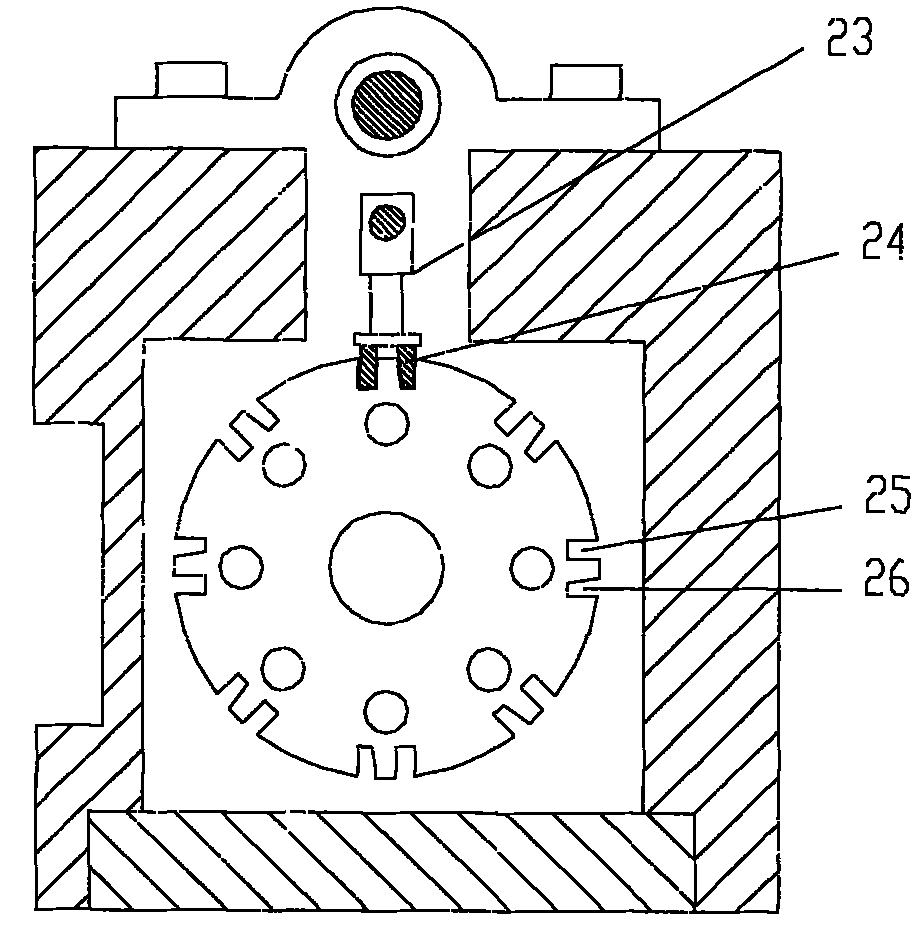

[0023] The basic structure of the bolt cold heading machine of the present invention is as follows: figure 1 As shown, it includes a body 3, a heading slider 1, a mold box 2, and a driving mechanism 11. The heading slider 1 is located in the slideway 10 in the body 3, and is connected between the crankshaft connecting rod 12 and the driving mechanism 11. The mold The box 2 is located on the opposite side of the heading slider 1, and is fixed on the supporting shaft 19 of the body 3 through bearings. The supporting shaft is also equipped with a gear 5 and a positioning wheel 4. The positioning wheel 4 is on the innermost side, and the gear 5 is in the middle. The positioning wheel 4, the gear 5 and the mold box 2 are fastened together to form a whole, the gear 5 is connected with the driving mechanism 11, and the positioning wheel 4 is connected with the driving mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com