Rubber composition for tire and tire manufactured by using the same

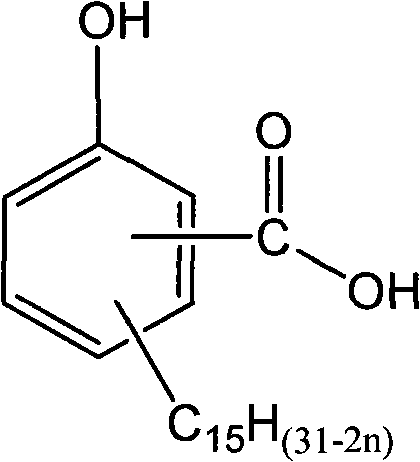

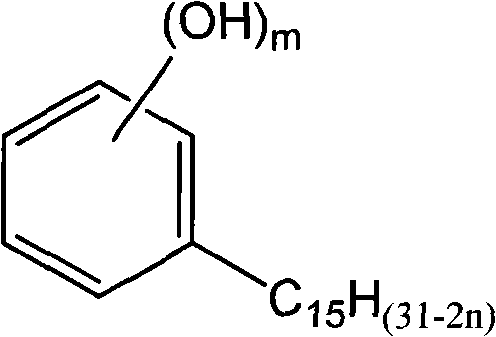

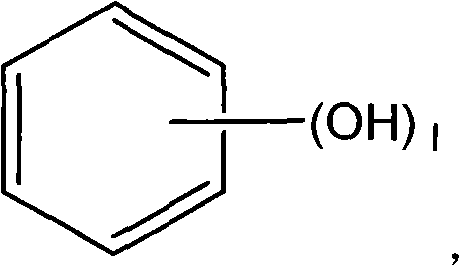

A rubber composition and tire technology, which is applied in special tires, tire parts, transportation and packaging, and can solve problems such as reducing work efficiency and adverse effects on the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0124] [Manufacturing example: Manufacturing of rubber composition]

[0125] The rubber compositions for tires according to the following Examples and Comparative Examples were produced using the compounding ratio shown in Table 1 below. For the production of the rubber composition for tire treads, refer to the production method of general tire tread rubber.

[0126] [Table 1] (Unit: parts by weight)

[0127] Item

Comparative example 1

Example 1

Example 2

Example 3

Example 4

80

80

80

80

80

E-SBR (1)

20

20

20

20

20

Carbon black A (2)

30

30

30

30

30

Carbon black B (3)

45

45

45

45

45

Cashew nut shell liquid resin A (4)

14

-

-

-

-

Cashew nut shell liquid resin B (5)

-

14

18

14

14

Softener

3.5

3.5

3.5

3.5

3.5

HMTA (6)

0.8

0.8

0.8

1.3

1.3

Vulcanization accelerator 1 (7)

1.2

1.2

1.2

1.2

1.2

Vulcanizing agent (sulfur)

3

3

3

3

2.5

[0128] (1) E-SBR: Emulsified polymerized...

Embodiment 3

[0153] Example 3 is an example in which the methylene conjugate is further added than that of Example 2, and exhibits substantially improved physical properties. In the case of Example 4 in which the sulfur content as a vulcanizing agent is reduced, compared with Comparative Example 1, the hardness, Tanδ value, and low deformation characteristics have excellent results, and the tensile characteristics are also in the appropriate range, which is obvious The odor is reduced, and the physical properties are equivalent or better than those of Comparative Example 1.

[0154] In Example 4, which exhibited the lowest odor intensity, the scorch time also had an excellent value at the same level as that of Comparative Example 1, the hardness and modulus characteristics were also excellent, and the tensile strength and elongation were also in an appropriate range. In addition, the Tanδ value, which indicates the rolling resistance performance, is the best. Compared with Comparative Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com