Intelligent pressure-stabilizing stop-check valve

An intelligent, check valve technology, applied in the direction of functional valve types, control valves, safety valves, etc., can solve the problems of complex system installation, high cost of system equipment, low voltage stabilization accuracy, etc., and achieve high voltage stabilization accuracy and simplified Effect of installing equipment and preventing medium backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

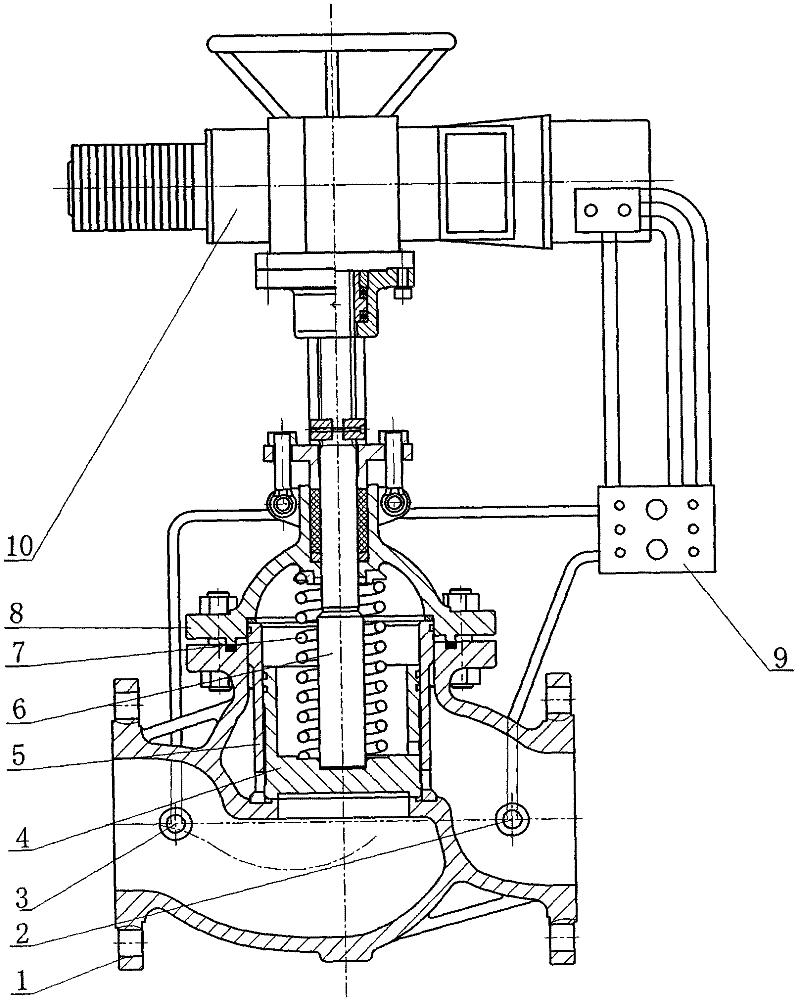

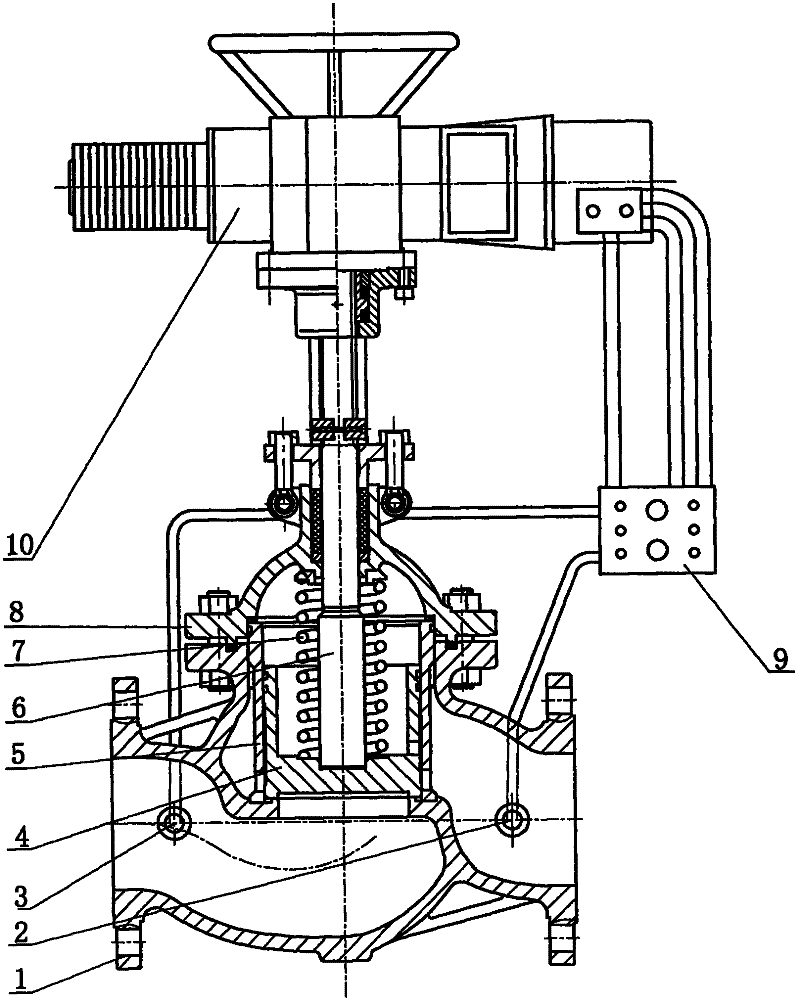

[0010] Such as figure 1 The intelligent cut-off and pressure-stabilizing check valve shown has a valve body 1, a valve disc 4, a valve stem 6, and a valve cover 8. There is a valve seat between the inlet channel and the outlet channel of the valve body 1, and a valve seat is formed on the lower plane of the valve disc 4. The sealing surface matched with the valve seat, the pressure setting spring 7 is provided between the upper plane of the valve disc 4 and the valve cover 8, and a cylindrical guide sleeve 5 is provided in the valve cavity on the outlet side of the valve seat, and the lower end surface of the guide sleeve 5 is fixed. It is installed on the valve body 1 on the periphery of the valve seat, and the upper end surface is press-fitted under the valve cover 8 . The outer peripheral surface of the valve disc 4 is movably matched with the inner wall of the guide sleeve 5, and a spring chamber is formed among the guide sleeve 5, the valve disc 4 and the valve cover 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com