Bottom device of electric calcining furnace

A bottom device and electric calciner technology, applied in the direction of electric furnace heating, furnace cooling, etc., can solve the problems of effective height waste, poor operating environment, large porosity of paste, etc., and achieve the effect of avoiding collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

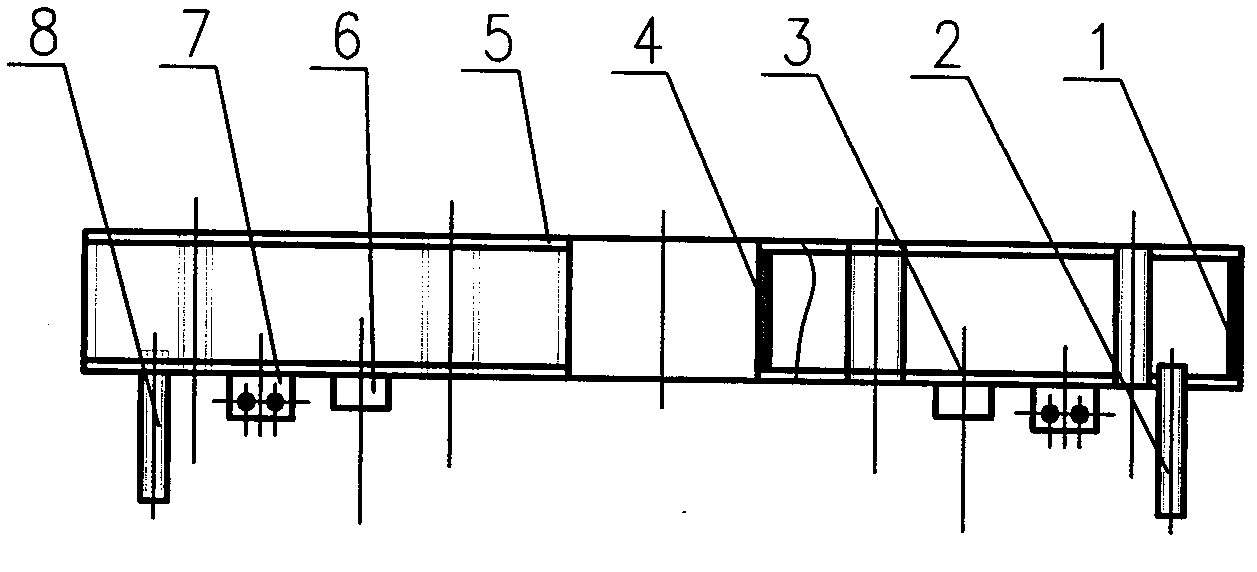

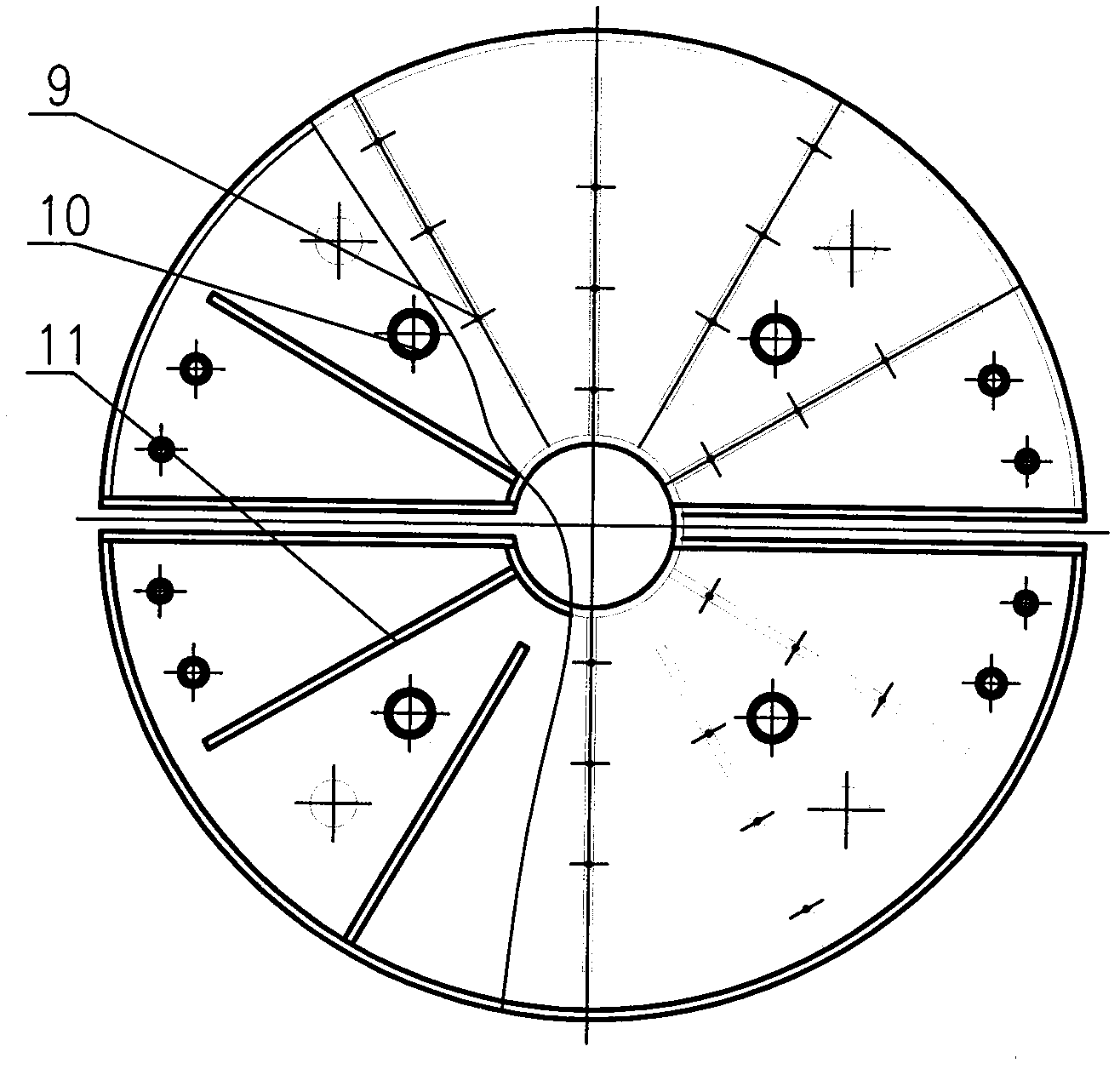

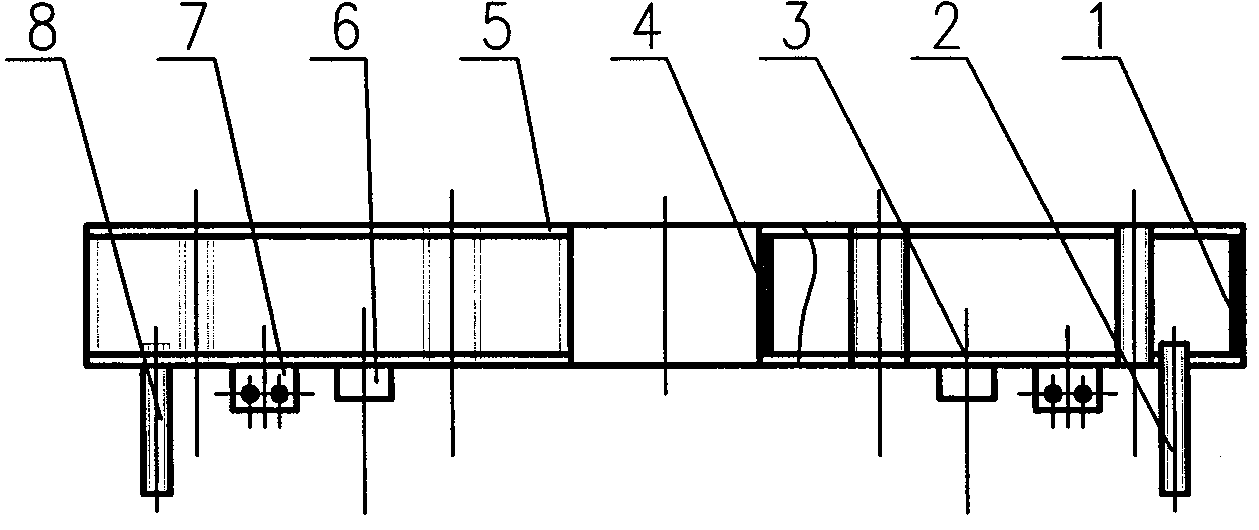

[0015] Such as figure 1 and figure 2 As shown, the bottom device of the electric calciner of the present invention has the following structure: a circular main structure is formed by a plurality of independent hollow fan-shaped cylinders, and the inside of the hollow fan-shaped cylinders is divided into a plurality of cooling water chambers by longitudinally arranged support plates 11, Adjacent support plates 11 are arranged in a staggered manner to facilitate the circulation of cooling water. Water inlet pipes 2 and outlet pipes 8 are respectively provided at the lower part of each hollow fan-shaped cylinder, and the lower ends of adjacent hollow fan-shaped cylinders are connected by connecting plates 7. , the steel pipe 10 runs through the hollow fan-shaped cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com