Processing method for engineering diamond core drill matrix

A processing method and thin-wall drill technology, which are applied in the field of thin-wall drill bit manufacturing, can solve the problems of high scrap rate, large loss and low efficiency, and achieve the effect of reducing the loss of raw materials and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

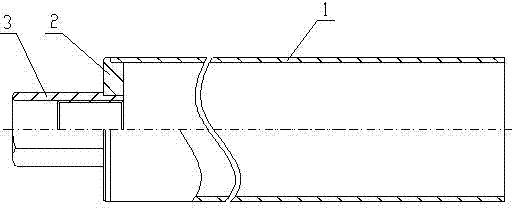

[0025] see figure 1 , the present embodiment is a kind of processing method of diamond engineering thin-walled drill matrix, firstly determine the composition of diamond engineering thin-walled drill matrix, it is made up of three parts of steel pipe body 1, joint piece 2 and joint 3, wherein, steel pipe body 1 The raw material is obtained by cold gadolinium, the outer diameter of the joint piece 2 and the outer diameter of the steel pipe body 1 are machined and polished to the same size after welding, and the shape of the joint 3 is hexagonal nut shape.

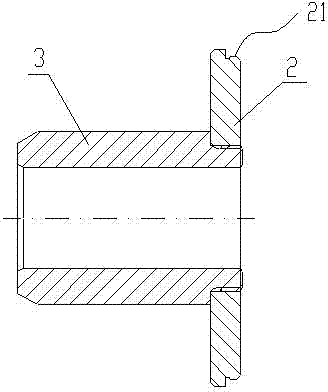

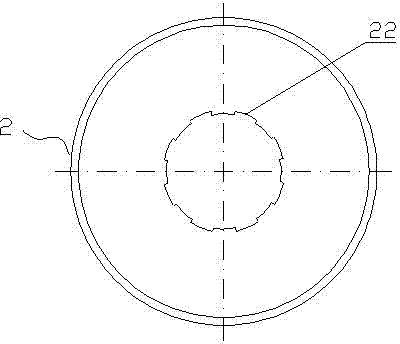

[0026] The joint piece 2 and the steel pipe body 1 are connected with a boss 21, such as figure 2 As shown, the outer diameter of the boss 21 is in clearance fit with the inner diameter of the steel pipe body 1 . Eight tooth recesses 22 are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com