Tube body forming structure of fluorescent tube processor

A fluorescent lamp tube and processing machine technology, applied in glass forming, glass re-forming, manufacturing tools and other directions, can solve the problems of low processing efficiency, high labor intensity of workers, etc., and achieve fast forming speed, simple structure and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

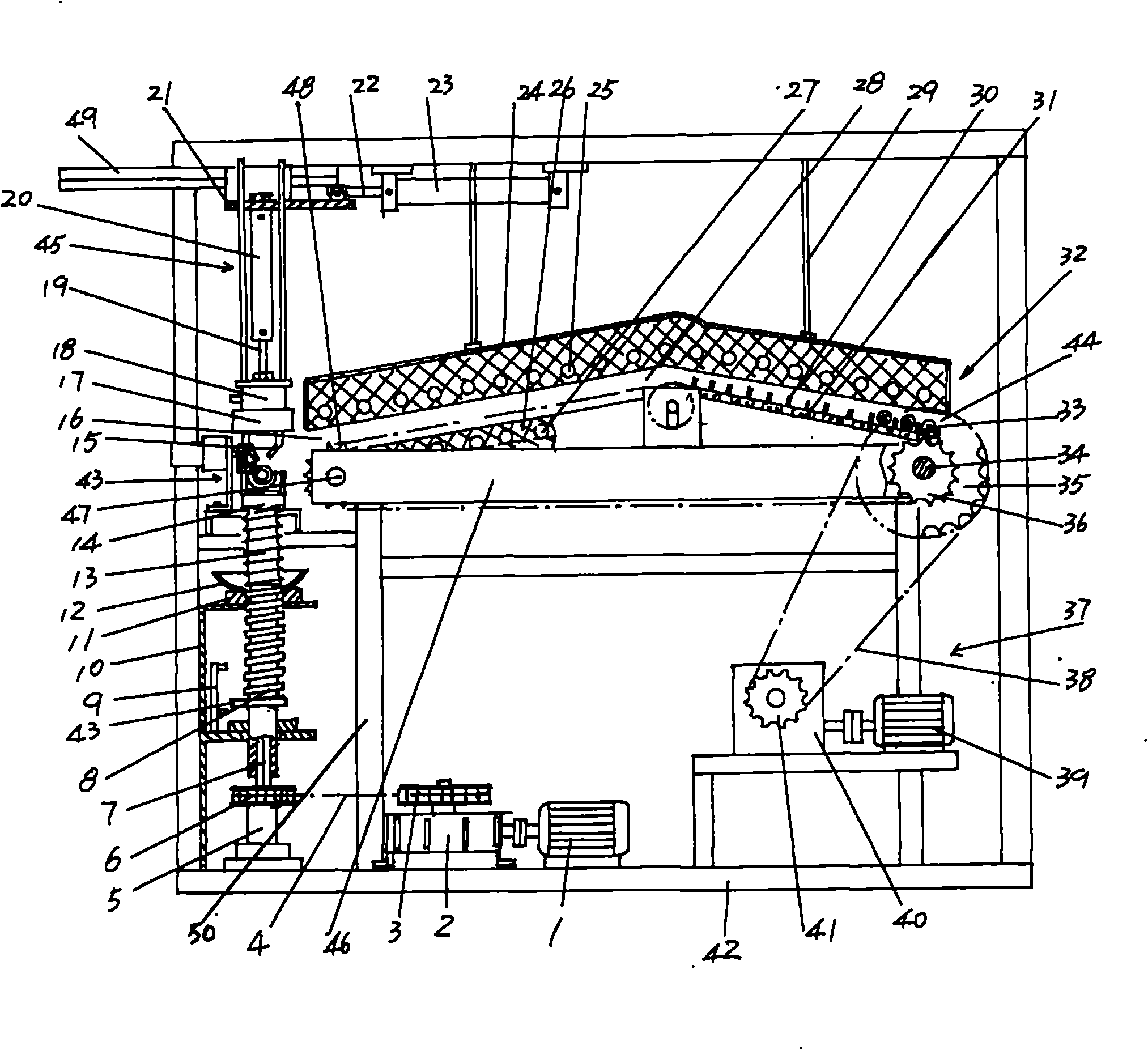

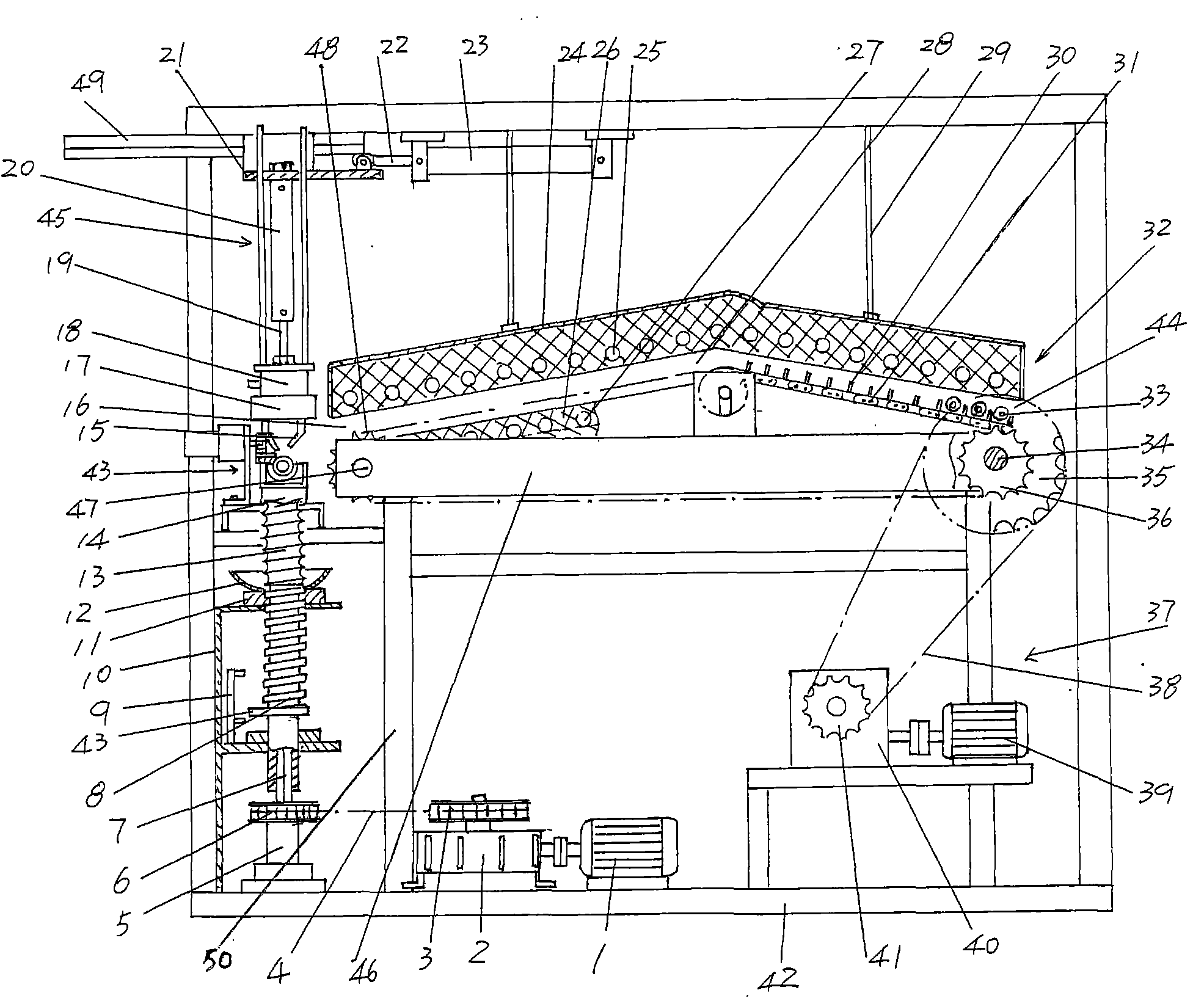

[0010] Please refer to the accompanying drawings, taking the current illustrated position as an example, the spiral lamp tube forming mechanism of the present invention is arranged below the left side of the frame 42 of the lamp processing machine, specifically: it will be fixed on the frame The first motor 1 with forward and reverse functions at the bottom of 42 is connected to the power input shaft of the first reducer 2 through a coupling, and the first reducer 2 is fixed on the bottom of the frame 42. The first sprocket 3 is fixed on the power output shaft of the first stage, and one end of the first chain 4 is sleeved on the first sprocket 3, and the other end of the first chain 4 is sleeved on the second sprocket 6, and the second sprocket 6 is fixed on the square shaft 7, the lower end of the square shaft 7 is pivoted on the shaft support 5, and the shaft support 5 is fixed on the frame 42, the upper end of the square shaft 7 is fixedly connected with the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com