PTT (polytrimethylene terephthalate) low stretch yarn with wool-like effect and preparation method thereof

A low-elasticity, wool-like technology, used in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of poor wool feel, difficult to eliminate creases, hard feel, etc., and achieve outstanding wool-like effect. , the effect of excellent wool-like effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

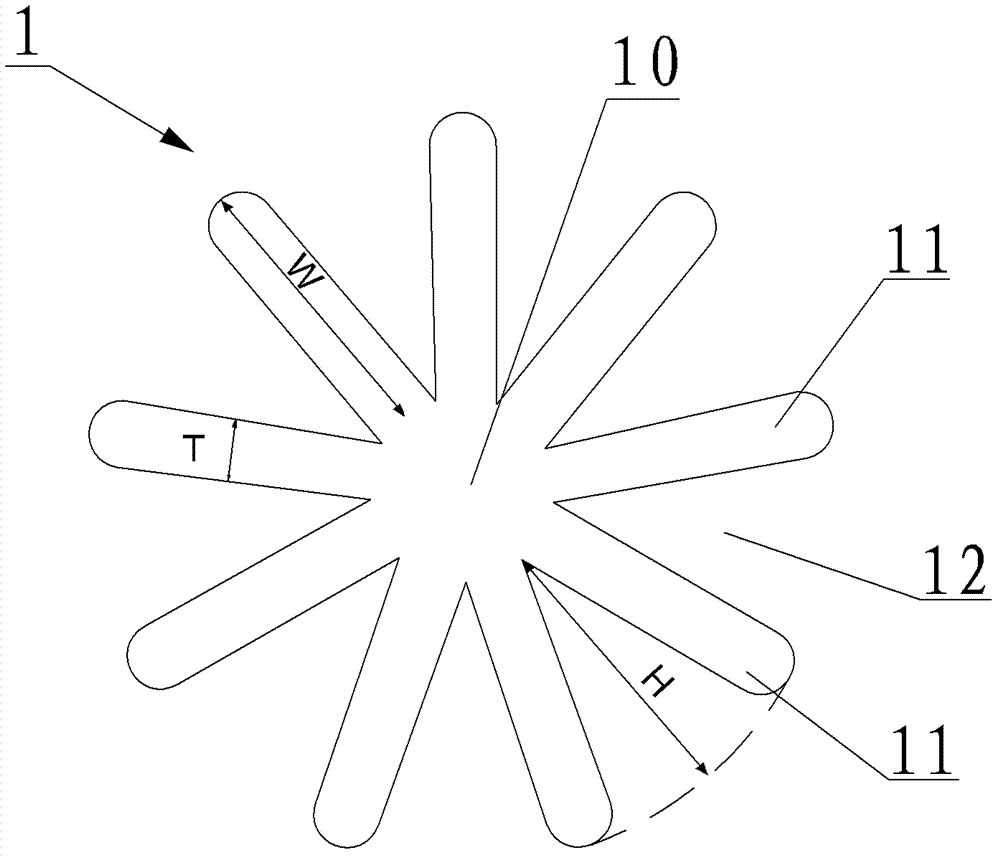

[0028] Such as figure 1 As shown, the present embodiment provides a PTT low-strength yarn, the cross section of which is nine-toothed, specifically comprising a core 10 with a circular cross-section and nine toothed shapes evenly distributed along the outer circumference of the core 10 part 11, and a groove 12 with a depth of 0.04~0.08 mm is formed between two adjacent toothed parts 11. The thickness T of the tooth-shaped portion 11 is 0.02-0.06 mm, and the width W is 0.04-0.08 mm. The low-stretch yarn with this structure has a particularly good wool feeling.

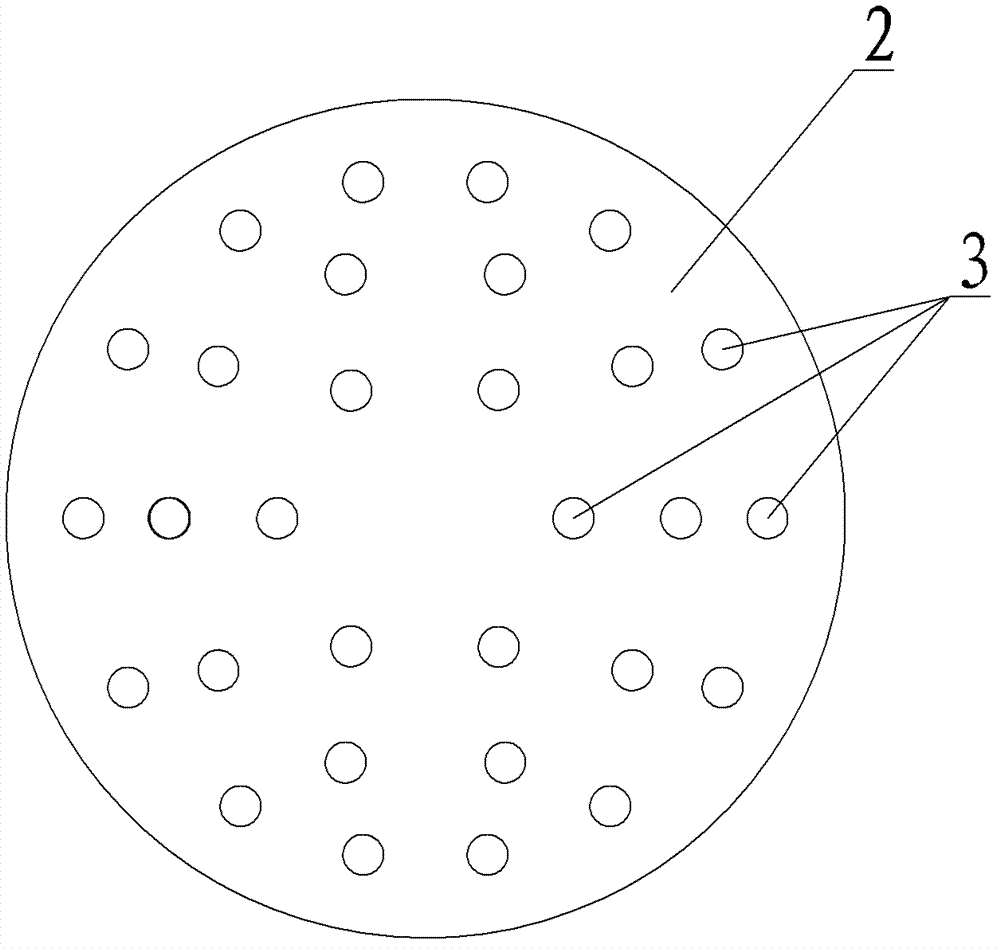

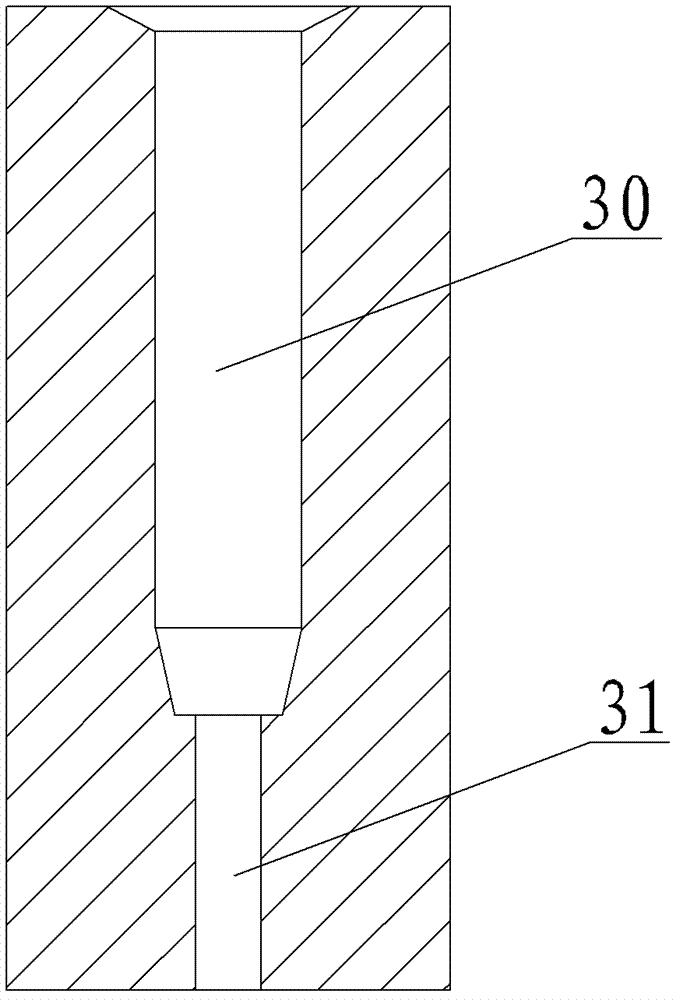

[0029] The PTT low stretch wire can be used in hole types such as figure 2 and 3 The spinneret shown was produced. The spinneret has a conventional spinneret structure: it includes a spinneret body 2 and a plurality of spinneret holes 3 regularly distributed on the spinneret body 2, each spinneret 3 includes a guide hole 30 and a spinneret Capillary 31. In particular, the cross-section of the spinneret capillary ...

Embodiment 2

[0031] This example provides a method for preparing elastic fibers with wool-like effect (fiber specification is 150 / 48dtex / f), which is specifically as follows:

[0032] (1) Dry the PTT chips with a viscosity of 0.98 at 135°C. After drying for 8 hours, melt them through a screw at a melting temperature of 230-265°C, extrude to obtain a melt, and send the melt into the spinning box. After metering, it is sent into the spinning assembly at the bottom of the spinning box, and finally extruded from the spinneret of the spinning assembly to form a nascent fiber with a nine-toothed cross section. See Table 1 for the spinning conditions. The spinneret is figure 2 and 3 The spinneret shown, and the spinneret capillary of the spinneret is nine-tooth type, the distance between the plate surface of the spinneret and the cooling zone is 1cm~2cm, and the air volume of the cooling zone is 0.7m / min~ 0.9m / min, the cooling temperature is controlled between 14°C and 15°C;

[0033] (2) After...

Embodiment 3

[0037]This example provides a method for preparing elastic fiber with wool-like effect (fiber specification is 200 / 65dtex / f), which is basically the same as Example 2, but the spinning conditions are slightly different. The performance index of the elastic fiber is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com