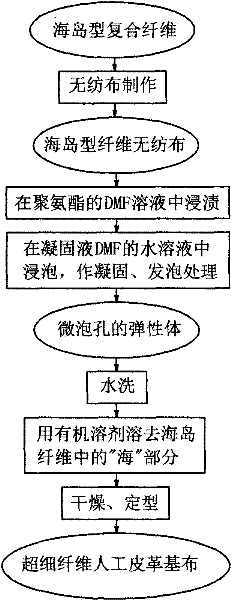

Method for preparing composite superfine fiber artificial leather base fabric

A technology of artificial leather and microfiber, applied in fiber treatment, conjugated synthetic polymer artificial filament, non-woven fabric, etc., can solve the problems of low physical properties of synthetic leather, low island phase components, and many fiber voids, etc. Achieve the effect of uniform fluff length, uniform distribution and uniform fluff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

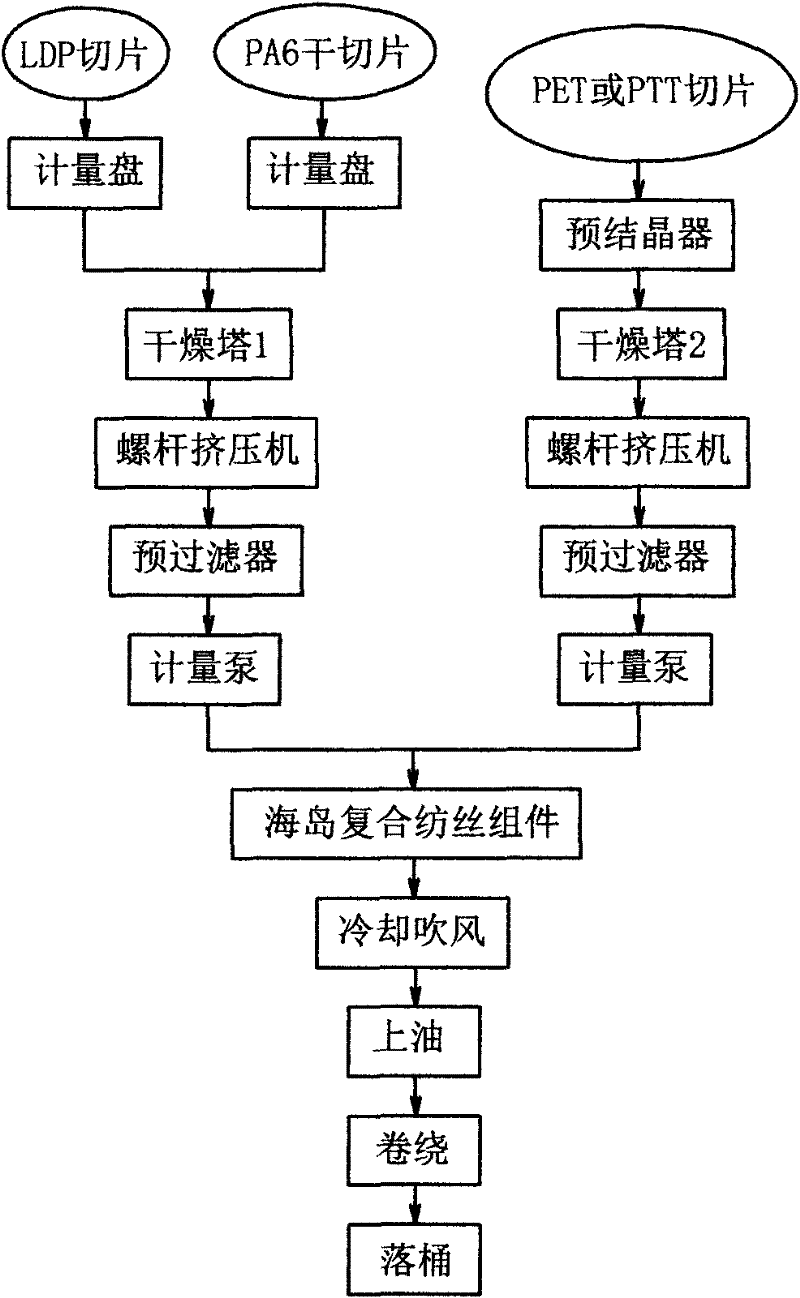

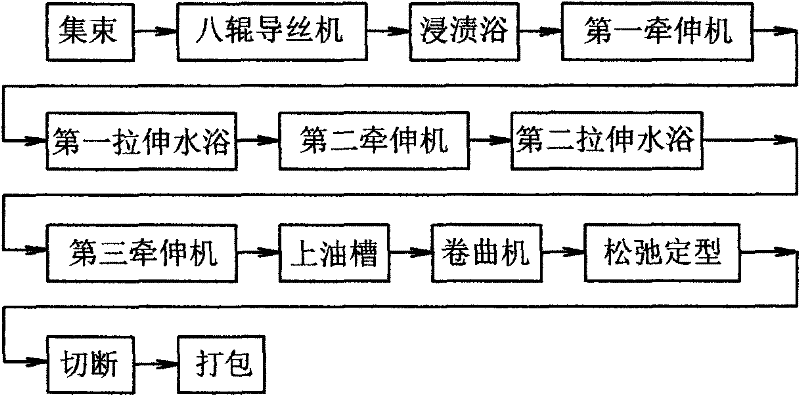

[0080] Example 1: Preparation of leather base cloth for vehicles

[0081] (a) Spinning raw materials:

[0082] Fixed island component: polyester chips, viscosity 0.64dl·g -1 ;

[0083] Sea component: a blend of LDPE with a melt index of 50MFI and PA6 with a viscosity of 2.8η, where:

[0084] PE, grade MB9500, melt index 50, produced by South Korea’s LG company,

[0085] Nylon chips, grade M32800, relative viscosity is 2.8η;

[0086] (b) Raw material ratio: weight ratio: PET / (LDPE+PA6)=50 / (25+25);

[0087] (c) Sea-island spinneret specifications: number of holes×number of islands×aperture of 520×16×0.35mm;

[0088] (d) Screw extruder: specification 105, length to diameter ratio L / D=30:1;

[0089] (e) Metering pump specification: 15cc / rev;

[0090] (f) Cooling air temperature: 16℃, wind speed: 2.5m / s, static zone height: 25mm;

[0091] (g) Rotation speed of oil pan: 22rpm / min, oil concentration: 1.5%;

[0092] (h) Spinning (winding) speed: 400m / min;

[0093] (i) Spinning process and physical prop...

Embodiment 2

[0109] Example 2: Preparation of elastic leather base cloth

[0110] (a) Spinning raw materials:

[0111] Fixed island component: PTT slice, intrinsic viscosity 1.10dl·g -1 ;

[0112] Sea component: a blend of LDPE with a melt index of 50MFI and PA6 with a viscosity of 2.6η, where:

[0113] PE, grade MB9500, melt index 50, produced by South Korea's LG company;

[0114] Nylon chips, grade M32600, relative viscosity is 2.6η;

[0115] (b) Raw material ratio: weight ratio: PTT / (LDPE+PA6)=50 / (25+25);

[0116] (c) Sea-island spinneret specifications: number of holes×number of islands×aperture of 520×16×0.35mm;

[0117] (d) Screw extruder: specification 105, length to diameter ratio L / D=30:1;

[0118] (e) Metering pump specification: 15cc / rev;

[0119] (f) Cooling wind temperature: 16℃, wind speed: 2.0m / s, static zone height: 25mm;

[0120] (g) Rotation speed of oil pan: 22rpm / min, oil concentration: 1.5%;

[0121] (h) Spinning (winding) speed: 400m / min;

[0122] (i) Spinning process and physical prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com