High-efficiency cluster type water pump system with constant pressure and variable flow and operation control method

A water pump system and variable flow technology, applied in pump control, water supply pipeline system, pumping station, etc., can solve problems such as unreasonable water pump configuration, insufficient water supply, waste of electric energy, etc., achieve significant energy saving effects, shorten start-up time, and save hardware The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

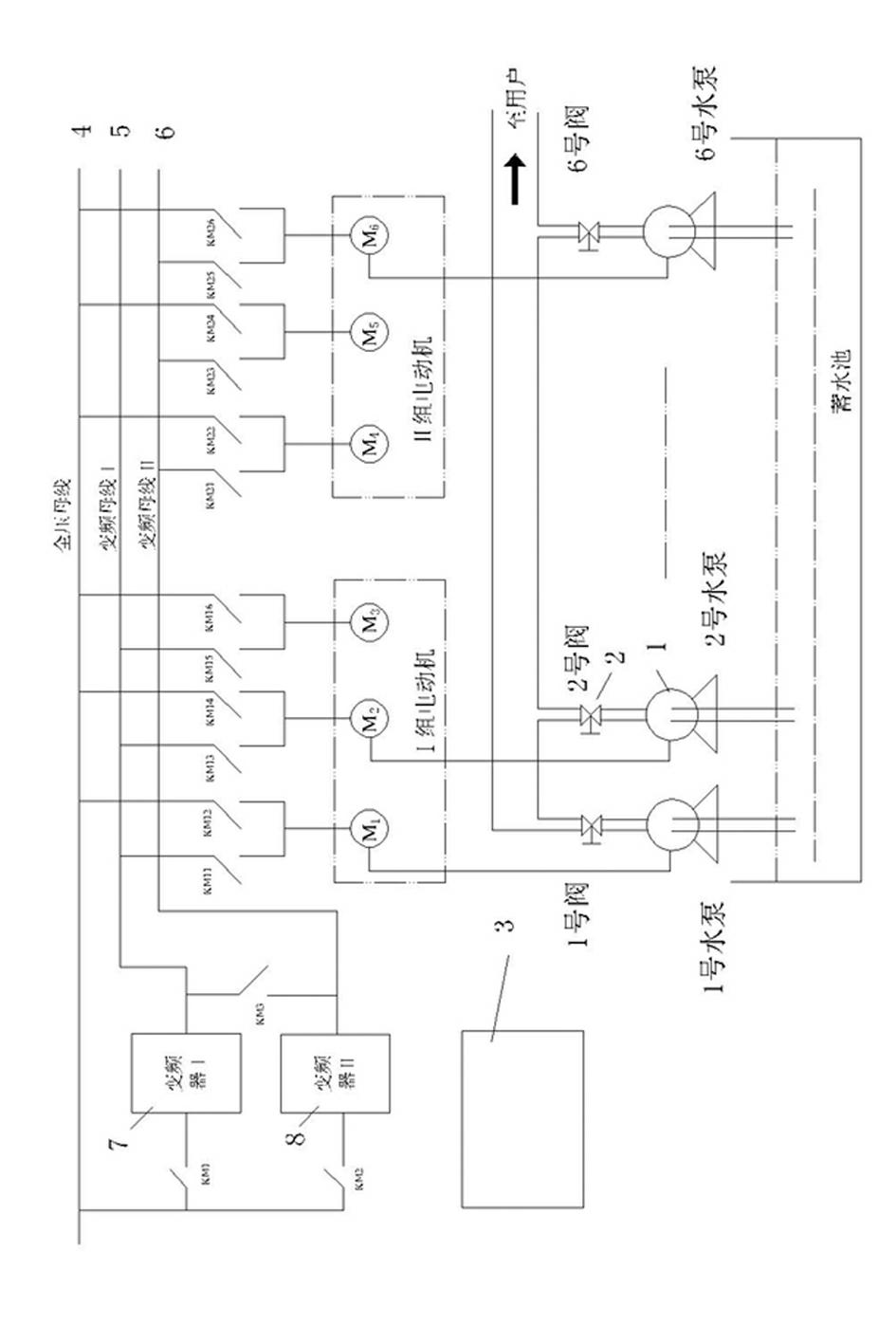

[0025] Such as figure 1 As shown, the clustered water pump system involved in the present invention includes a plurality of sequentially numbered water pumps 1, each of which is connected to a control valve 2, and the number of water pumps is determined according to the following method:

[0026] 1) First determine the operating conditions required by the user, including head, maximum flow and minimum flow; take head H=250m, maximum flow Qmax=550m 3 / hour, minimum flow Qmin=150 m 3 / hour as an example.

[0027] 2) Take the minimum flow rate and head demand of the working condition as the rated flow rate Q of a single pump 1 N and rated head H N , and then by the efficiency η of the actual water pump N To select the rated rated shaft power parameter P N =ρgQ N h N / (3600ηN ), ρ is liquid density, unit is Kg / m 3 , g is the gravitational acceleration, the unit is m / s squared; with Q N =150m 3 / hour, H N =250m, the rated efficiency of the pump is η N =0.74 as an exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com