Gas turbine combustor

一种燃气轮机、燃烧器的技术,应用在燃烧器、燃烧器、气体燃料燃烧器等方向,能够解决点火特性及火焰传播特性下降等问题,达到提高点火特性及火焰传播特性、减少NOx的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

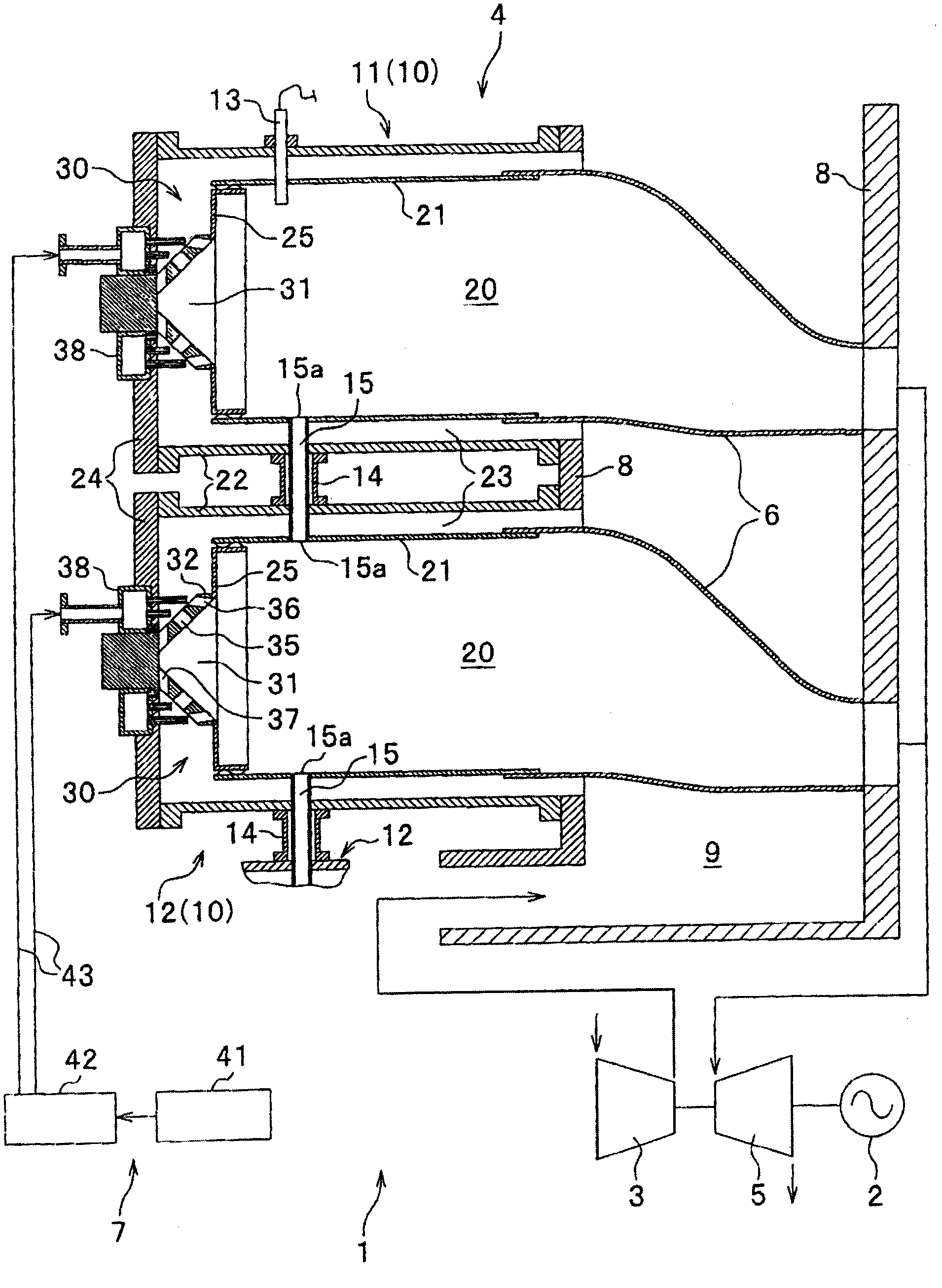

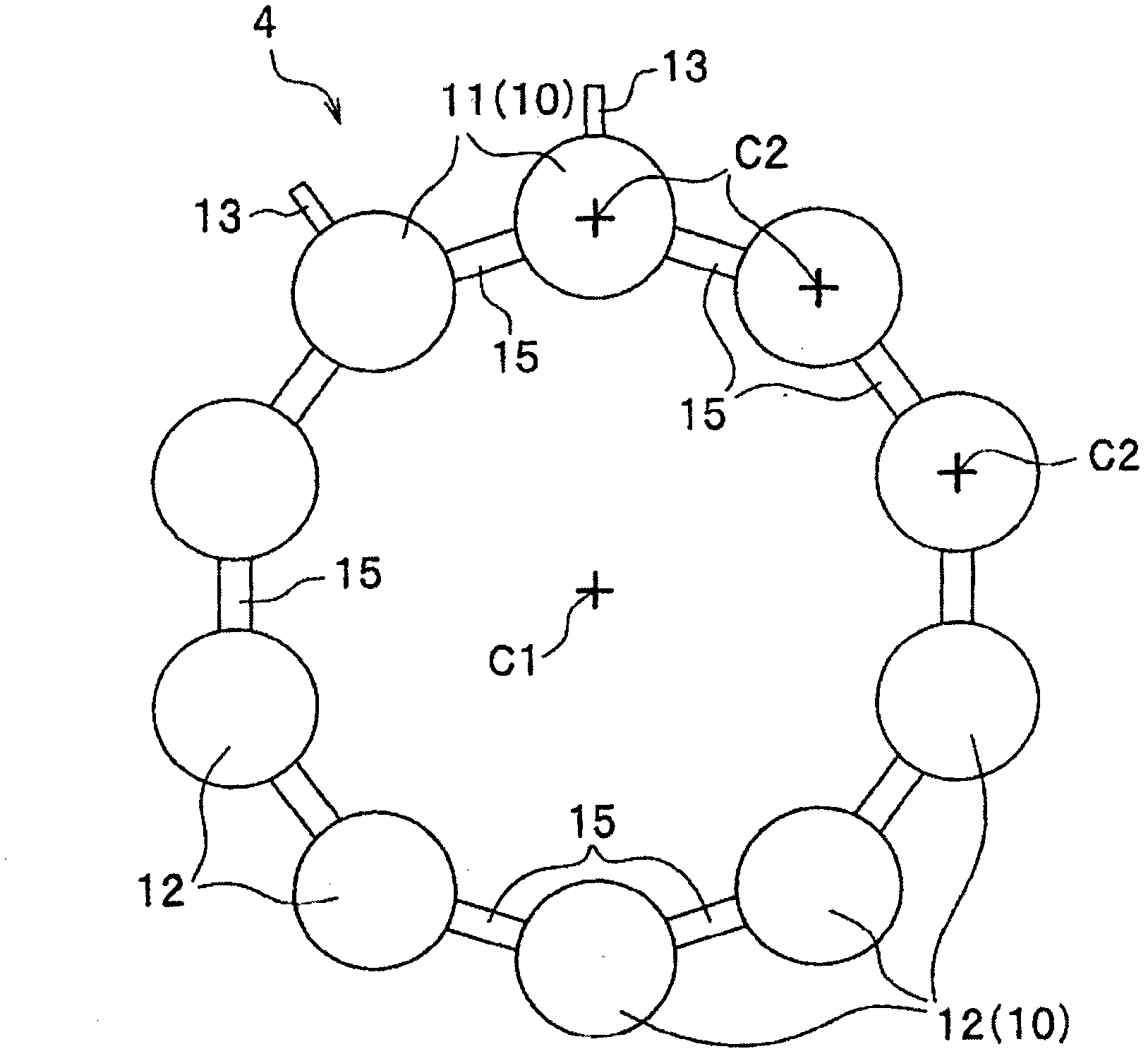

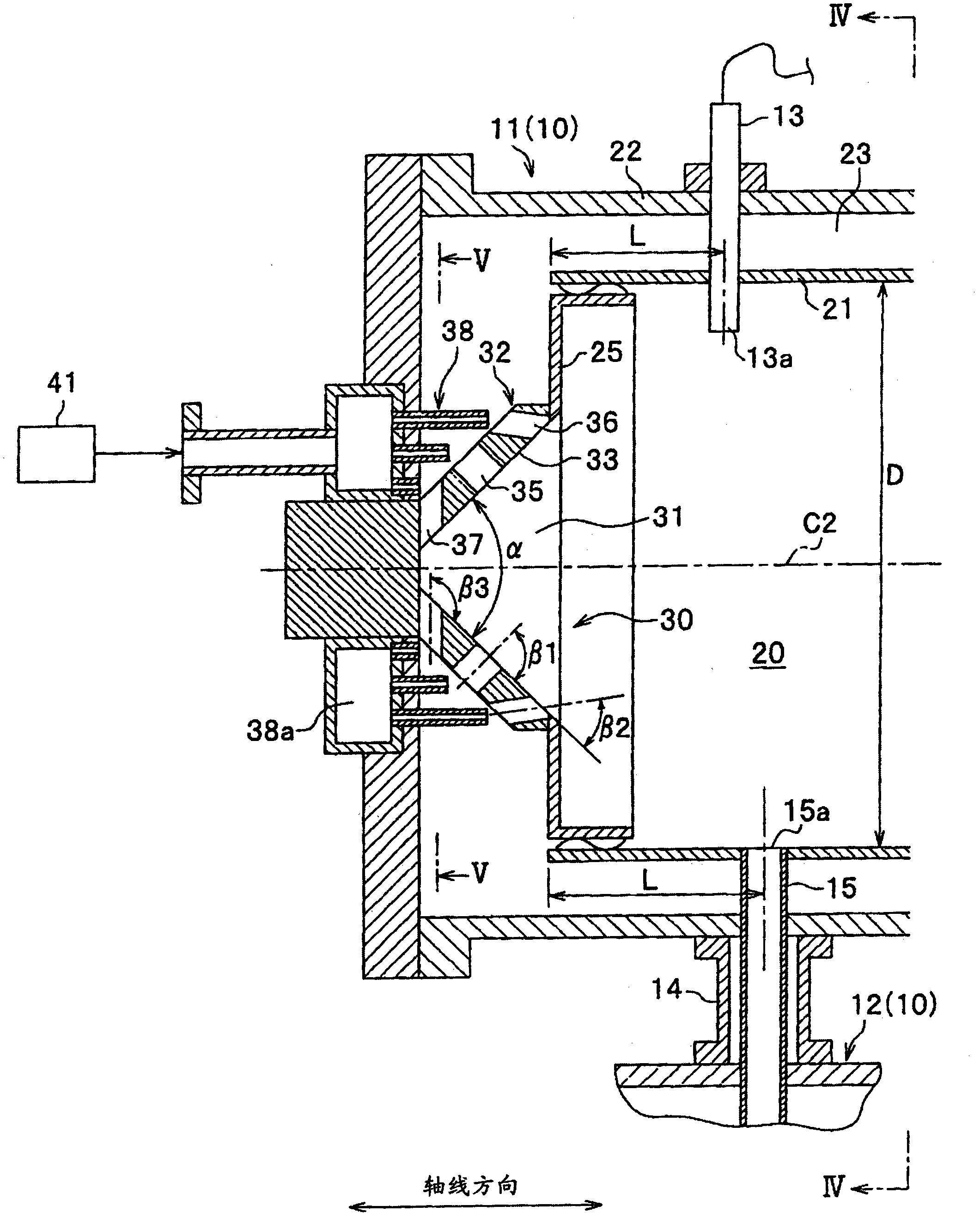

[0040] refer to Figure 1 to Figure 5 The gas turbine combustor 4 according to the first embodiment of the present invention will be described.

[0041] refer to figure 1 , the gas turbine facility including the gas turbine 1 is a gas turbine facility for power generation including the generator 2 to be driven by the gas turbine 1 .

[0042] The gas turbine 1 includes: a compressor 3 for compressing air; a gas turbine combustor 4 for combusting fuel to generate combustion gas by using combustion air which is a part of the compressed air obtained by the compressor 3; A turbine 5 that is driven to rotate by high-pressure combustion gas; a transition piece 6 that introduces the combustion gas from the gas turbine combustor 4 to the turbine 5; and a fuel supply system that supplies gas fuel (for example, liquefied natural gas) to the gas turbine combustor 4 7; and supports the casing 8 of the gas turbine combustor 4 while forming the casing 9 in which the compressed air discharg...

Embodiment 2

[0085] refer to Figure 7 ~ Figure 9 Embodiment 2 of the present invention will be described. In the second embodiment, a plurality of main burners 50 and 60 are arranged on the outer peripheral side of the burner 30, and the other structures are basically the same as those in the first embodiment.

[0086] In addition, in the second embodiment and the third and fourth embodiments described later, the description of the same parts as the first embodiment will be omitted or briefly described, and the differences will be emphasized in the description. In addition, the same symbols are used as necessary for the same or corresponding components as those of the first embodiment. In addition, Embodiments 2 to 4 have the same function and effect as Embodiment 1.

[0087] And, in embodiments two to four, the mixing chamber wall, the mixing chamber 31 and the fuel nozzle are respectively the central mixing wall, the central mixing chamber and the central fuel nozzle, and the mixing c...

Embodiment 3

[0111] refer to Figure 10 ~ Figure 12 Embodiment 3 of the present invention will be described.

[0112] refer to Figure 10 and Figure 11 The burners 70 and 80 of the burner 10 included in the gas turbine combustor 4 of the third embodiment are constituted by the pilot burner 70 corresponding to the burner 30 of the second embodiment, and the main burner 80 .

[0113] The pilot nozzle 70 has a mixing chamber wall 72 forming a conical mixing chamber 71 opened toward the downstream in the axial direction, and a fuel nozzle 79 as a center nozzle for supplying fuel. The mixing chamber wall surface 73 of the mixing chamber wall 72 is formed in a conical shape, and forms the conical mixing chamber 71 .

[0114] In addition, on the mixing chamber wall 72, a plurality of air introduction holes 75 and 76 for introducing combustion air, or introducing combustion air and fuel together into the mixing chamber 71 are arranged in the axial direction in first and second rows R1 and It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com