Cutting slit separation device of cocoon

A separation device and silkworm cocoon technology, applied in animal husbandry and other directions, can solve the problems of large size gap of silkworm cocoons, low work efficiency, immature technology, etc., and achieve the effect of flexible clamping action, compact structure and adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

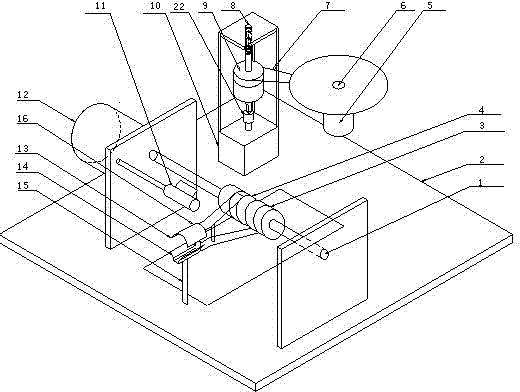

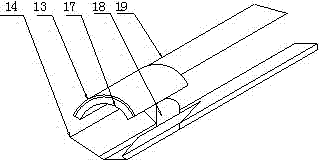

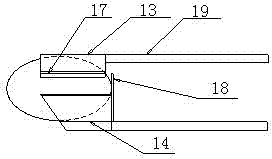

[0022] Such as Figure 1 to Figure 4 As shown, bearings are installed at both ends of the main shaft 1, and one end is connected with the stepping motor 12 driven by the rotation of the main shaft. The clamping mechanism is composed of an arc finger 13 and a V-shaped finger 14. The arc-shaped finger 13 is connected, and the arc-shaped inner surface is provided with an elastic gasket 17, which can be deformed to a certain extent along with the shape of the silkworm cocoon. The V-shaped finger 14 is connected with the V-shaped finger electromagnetic clutch by clamping the rotating arm 16. The front end of the V-shaped finger 14 is an approximate V-shaped groove, and an upright baffle plate 18 is housed at the V-shaped groove rear end of the V-shaped finger, and the effect is to One end of the silkworm cocoon is tight, and the vertical baffle sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com