Vibration sheller

A technology of shelling machine and vibrating motor, which is applied in the field of shelling machine, can solve the problems affecting the economic benefits of shellfish processing enterprises and cannot meet the order demand, and achieve the effect of simple structure, long service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

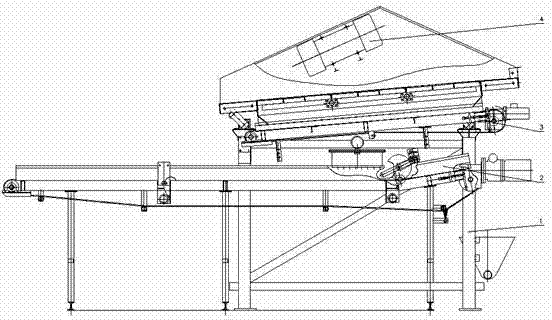

[0015] Such as figure 1 As shown, a vibrating shelling machine includes a main frame body 1, a recoil conveyor 2, a meat conveyor 3 and a vibrating motor 4, the recoil conveyor 2 is placed in the main frame body 1, and the The meat conveyor 3 is connected with the recoil conveyor 2, and the vibration motor 4 is installed on the main frame body 1.

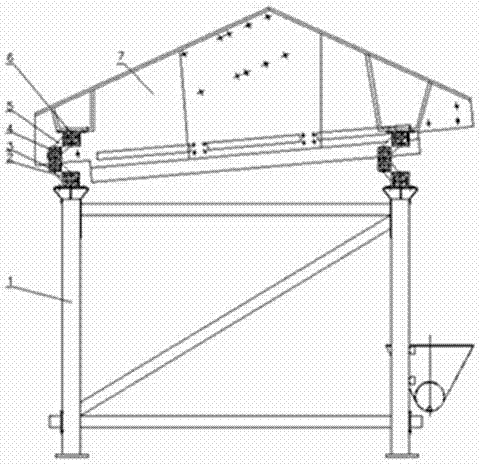

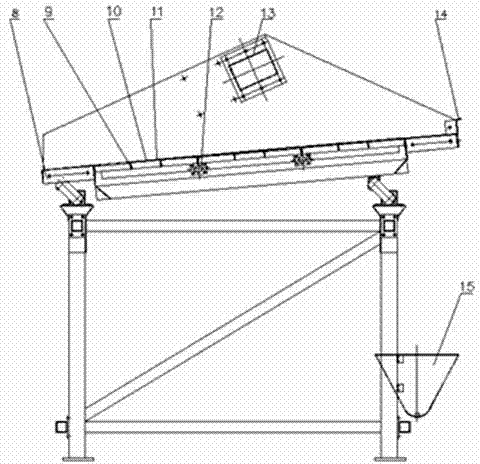

[0016] Such as figure 2 , image 3 As shown, the main frame body 1 includes an underframe, a shock absorbing device, a baffle device, a grid frame, a screen and a pressing plate, and the described shock absorbing device is connected with the underframe and the baffle device, and the described baffle device is equipped with There is a grid frame, and the three grid frames can be connected by screws. The grid is equipped with a screen, and the screen is equipped with a pressing plate; the bottom frame is equipped with a slag bucket; the shock absorber It includes shock-absorbing part 1, shock-absorbing part 2, shock-absorbing rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com