Wood semigloss varnish composition and varnish and preparation method thereof

A technology of wood varnish and composition, applied in polyester coatings, coatings and other directions, can solve the problem of lack of matt wood varnish and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The preparation method of described varnish comprises the steps:

[0082] providing the components described in the composition above;

[0083] Stir and mix the modified short oil alkyd resin, special anti-scratch powder, additives for varnish and solvent, and disperse to obtain the varnish.

[0084] In one embodiment, pour 40-60% of the modified short-oil alkyd resin into the dispersion tank, add 1%-2% of the dispersant under the condition of constant rotation speed, and then slowly add the special anti-oxidant under low-speed stirring. Scoot 5-15%, then stir at high speed until the fineness is qualified, add 0.5-1% of anti-settling agent, 0.1-0.5% of defoamer, 0.1-0.5% of leveling agent, 1-5% of hand wax, and 15% of solvent ~ 20% and nitrocellulose 10 ~ 20%, high-speed stirring for 10 ~ 20 minutes to obtain the finished product.

[0085] The advantages of the present invention are:

[0086] The present invention aims to solve the problems of the prior art, and prov...

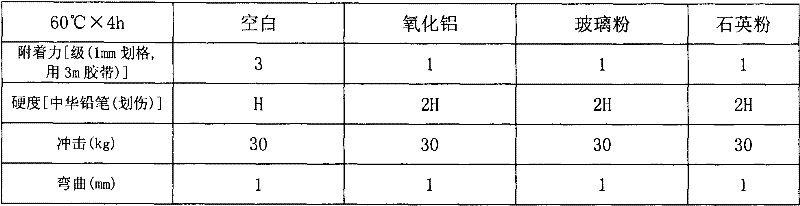

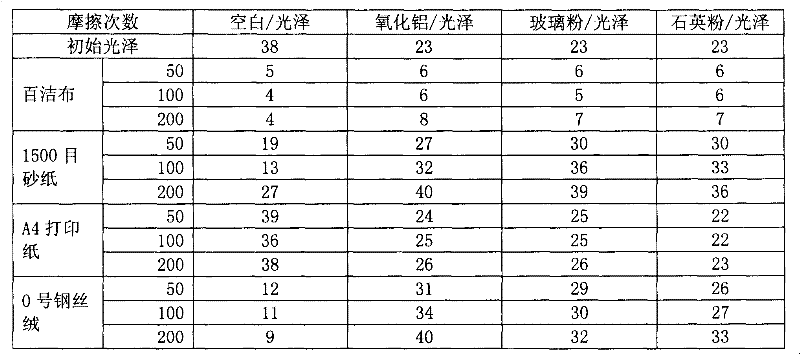

Embodiment 1

[0095] Pour 500g of 18 carbon castor oil modified Thor oleic acid short oil alkyd resin (purchased in Changxing Chemical Industry (China) Co., Ltd.) into the dispersing tank, slowly add 12g dispersing agent under the rotating speed of 1500rad / min, stir well Finally, the rotating speed drops to 1000rad / min, slowly add 100g 925 quartz powder (purchased from Sibelco (Shanghai) Mining Co., Ltd.) at this rotating speed, then increase the rotating speed to 2000rad / min, and maintain the rotating speed until the fineness is qualified Finally, add anti-settling agent (fumed silica) 8g, defoamer 2g (AFCONA2035), leveling agent (BYK 330) 2g, handle wax (BYK 988) 20g, solvent (PMA) 196g and nitrocellulose (purchased in Eternal Chemical Industry (China) Co., Ltd.) 160g, after high-speed stirring for 10-20min, the finished product was obtained.

[0096] After mixing the finished product and the polyurethane curing agent evenly in a ratio of 2:1, dilute it with a solvent (PMA or BAC or a mix...

Embodiment 1a

[0098] Example 1a is similar to Example 1, except that the defoamer is AFCONA 2045, the leveling agent BYK331, the handle wax BYK 998, and the solvent is BAC (butyl acetate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com