Coating interface treating agent and preparation method thereof

An interface treatment agent and coating technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of time-consuming, labor-intensive efficiency, easy to leave dead ends, uneven treatment, etc., to achieve convenient facade construction, moderate molecular weight, Migrating Flexible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The manufacture method of coating interface treatment agent, add 0.45 weight part n-butanol and 0.76 weight part cyclohexanone in 1 weight part butanone, then add 0.3 weight part titanate coupling agent NDZ-401 and 0.2 The parts by weight of LTH adhesion promoting resin are fully mixed, and finally 0.015 parts by weight of leveling agent BYK401 is added, and stirred and mixed evenly at room temperature.

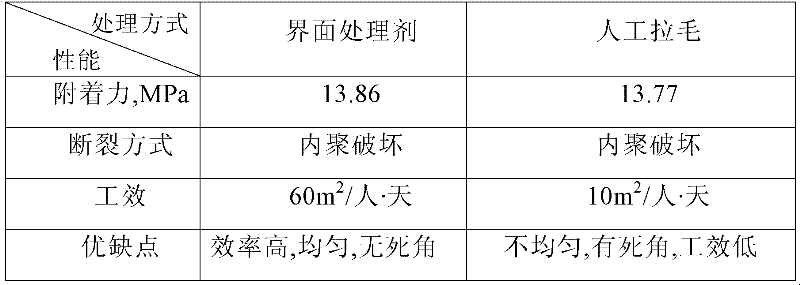

[0022] See Table 1 for the experimental results of the coating interface treatment agent in Example 1 and the artificial napping.

[0023] Table 1 Comparison table between interface treatment agent and artificial napping

[0024]

Embodiment 2

[0025] Embodiment 2: the manufacture method of coating interface treatment agent, add 0.4 weight part n-butanol and 0.7 weight part cyclohexanone in 1 weight part butanone, then add 0.3 weight part titanate coupling agent NDZ-401 and 0.1 The parts by weight of LTH adhesion promoting resin are fully mixed, and finally 0.01 parts by weight of leveling agent BYK410 is added, and stirred and mixed evenly at room temperature.

Embodiment 3

[0026] Embodiment 3: the manufacture method of coating interface treatment agent, add 0.6 weight part n-butanol and 0.9 weight part cyclohexanone in 1 weight part butanone, then add 0.5 weight part titanate coupling agent NDZ-401 and 0.3 The parts by weight of LTH adhesion promoting resin are fully mixed, and finally 0.03 parts by weight of leveling agent BYK410 is added, and stirred and mixed evenly at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com