Pressure container

A technology for pressure vessels and plastic containers, which is applied in the direction of pressure vessels, container filling methods, and the outer wall of container structures, which can solve the problems of reducing the sealing effect and achieve the effect of preventing radial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

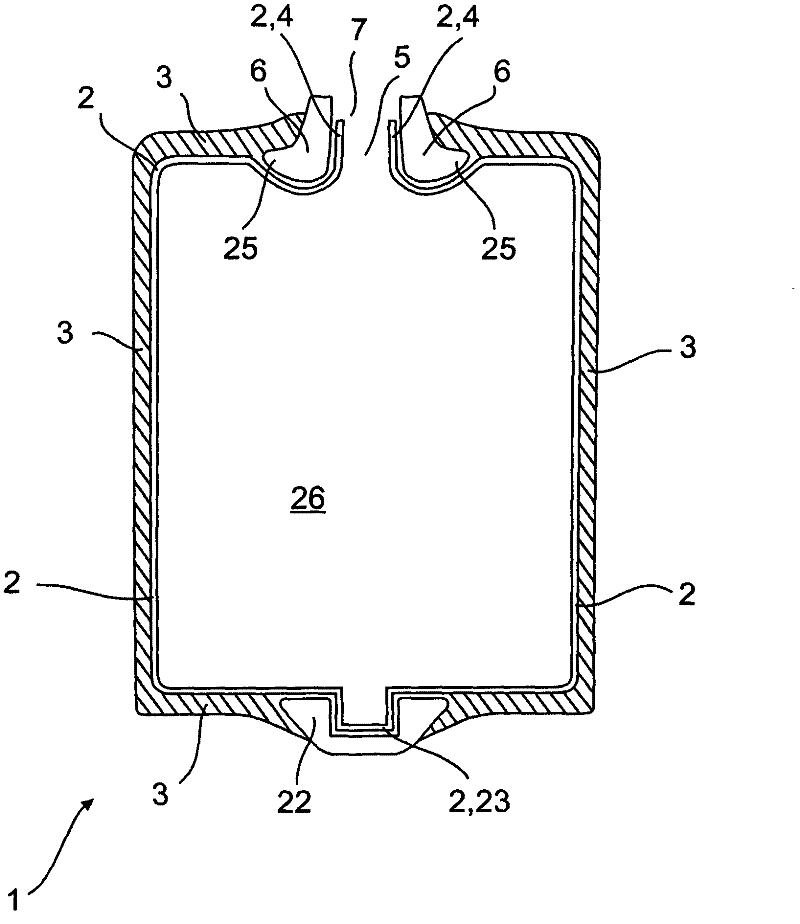

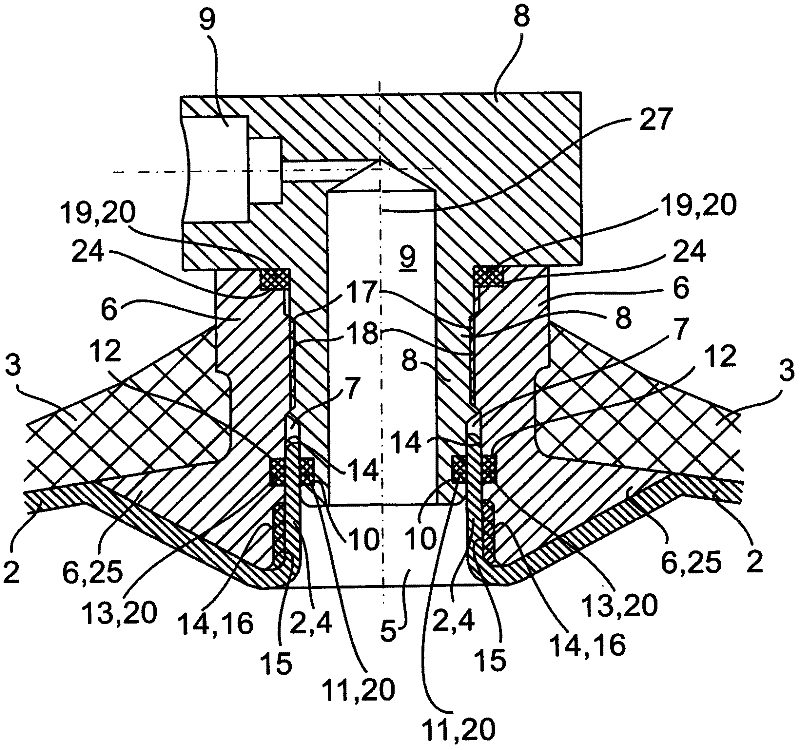

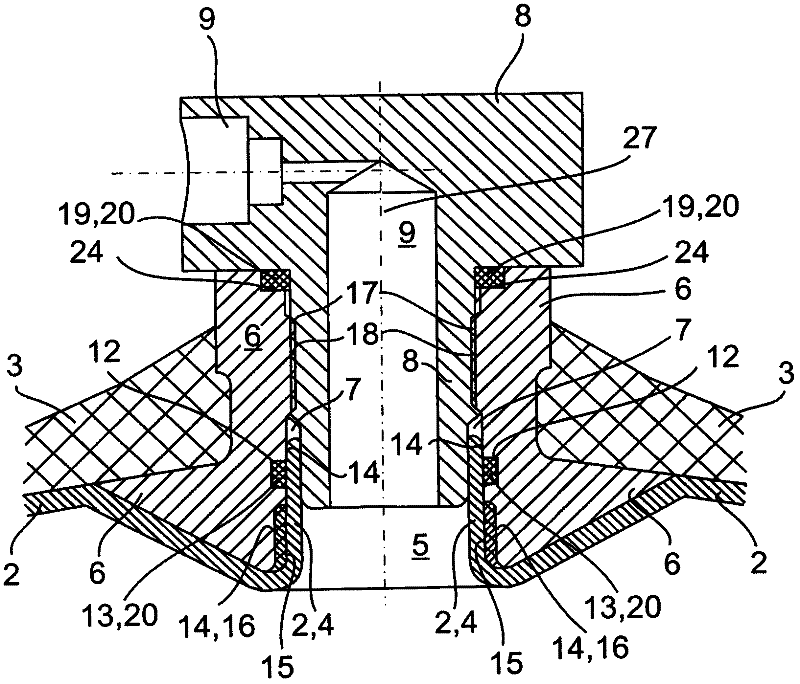

[0032] figure 1 The pressure vessel 1 shown is intended to contain a fluid under pressure, ie a liquid or a gas. The pressure vessel 1 has a plastic vessel core 2 or liner 2 which is produced from plastic, for example by means of blow molding or rotational sintering. The plastic container core 2 is surrounded by a support sleeve 3 . The support sleeve 3 is a fiber winding wound externally on the plastic container core 2 . For example the winding consists of reinforcing fibers such as carbon, aramid fibers, glass fibers, boron fibers, Al 2 o 3Fibers or their mixtures (hybrid filaments), which are embedded in a matrix of thermosetting plastics such as epoxy or phenolic resins or in thermoplastics such as PA12, PA6, PP. The support sleeve 3 thus consists of fibers and matrix and can absorb the pressure acting on the plastic container core 2 , which occurs because the fluid in the plastic container core 2 is stored under pressure. The fluid is thus stored or stored within the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com