Online density analyzing instrument

A density analysis and linear technology, applied in the field of density analyzers, can solve problems such as frequent and complicated equipment maintenance, the influence of accurate measurement of fluid density, and potential safety hazards of ray densitometers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the object, technical solution and advantages of the present invention clearer, the online density analyzer of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

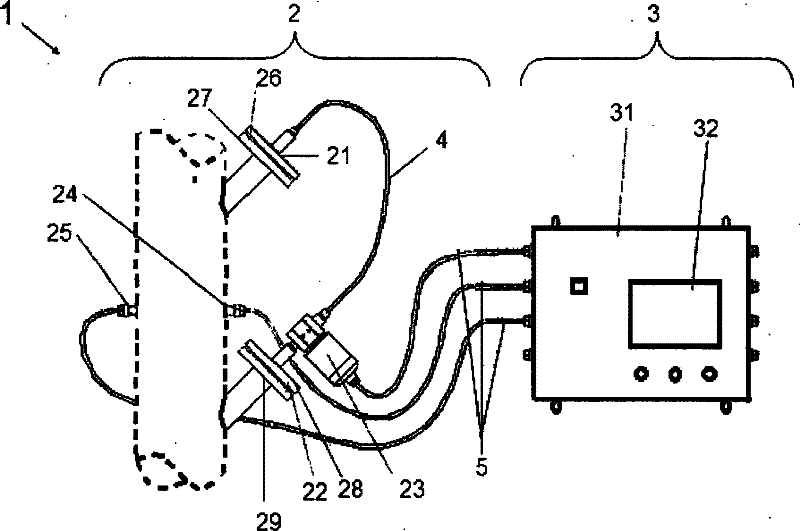

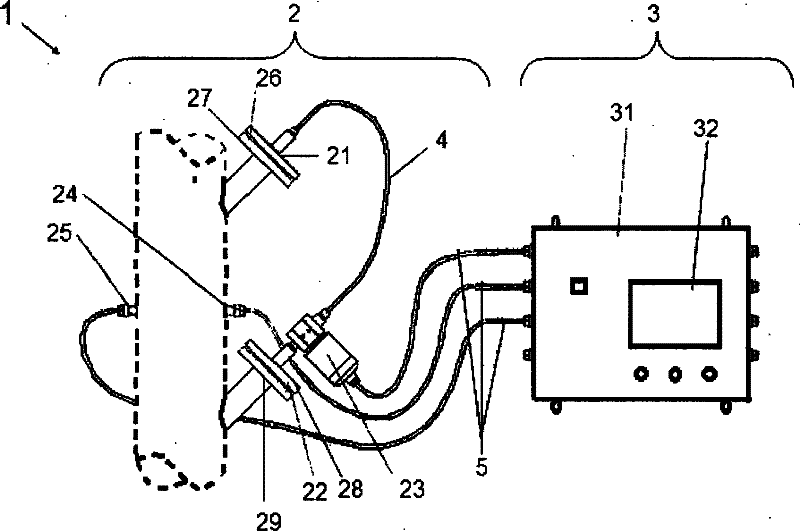

[0011] Such as figure 1 As shown, the online density and concentration analyzer 1 of the present invention includes a sensor measuring device 2 and a processing display device 3 .

[0012] Wherein, the sensor measurement device 2 includes a first differential pressure sensing diaphragm 21 , a second differential pressure sensing diaphragm 22 , a sensor 23 , a first ultrasonic probe 24 and a second ultrasonic probe 25 . Due to the use of the sensing diaphragm for density measurement, it has high sensitivity and high acquisition accuracy. The ultrasonic probe is used to quickly correct the change of the medium density, which can improve the measurement accuracy of the fluid density.

[0013] The first differential pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com