Parameter curve interpolation method based on vector interpolation of conical surface cutter

A technology of parametric curves and conical surfaces, applied in the field of CNC machining, can solve problems such as a large number of code segments, reduced machining accuracy, increased time and algorithm complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the accompanying drawings.

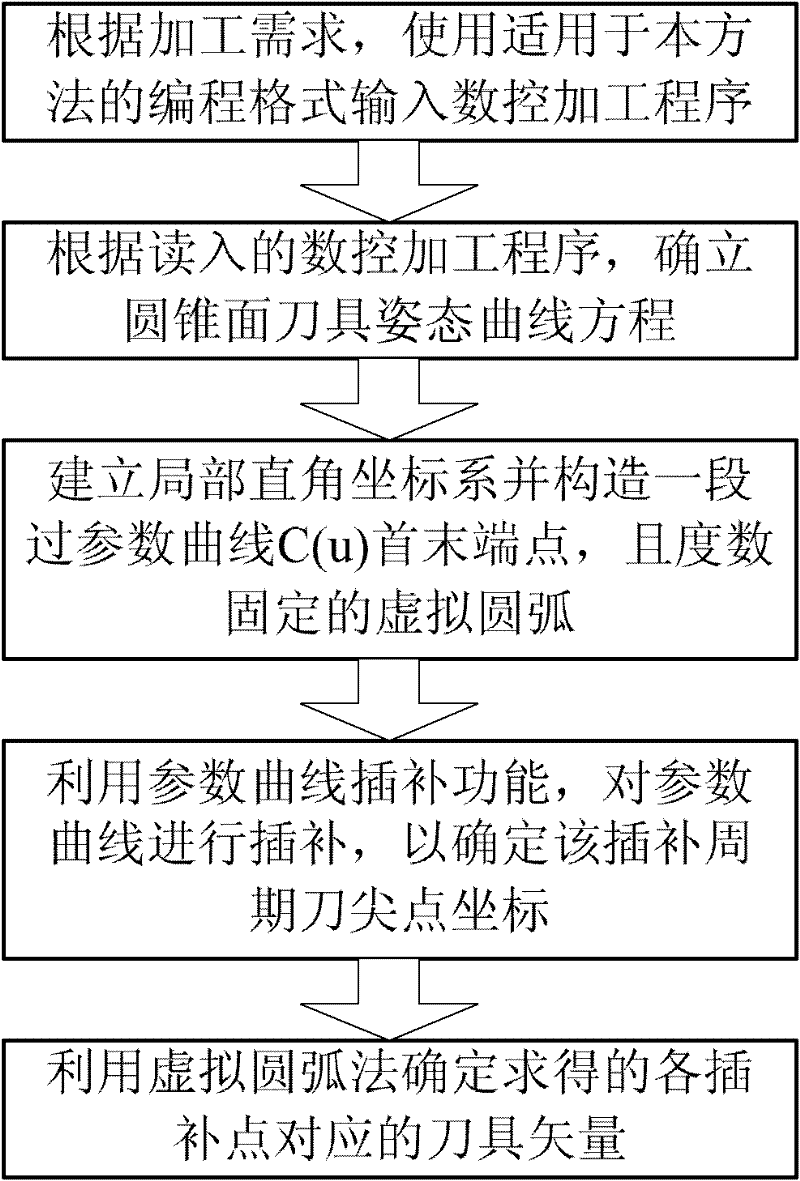

[0058] Such as figure 1 Shown, the present invention comprises the following steps:

[0059] According to the processing requirements, use the programming format applicable to this method to input the CNC machining program;

[0060] Establish the attitude curve equation of the conical surface tool according to the read-in NC machining program;

[0061] According to the read-in NC machining program, establish a local Cartesian coordinate system and construct a virtual arc with a fixed degree passing through the first and last points of the parameter curve C(u);

[0062] Use the parameter curve interpolation function to interpolate the parameter curve to determine the coordinates of the tool nose point in the interpolation cycle;

[0063] Use virtual arc method to determine the tool vector corresponding to each interpolation point obtained.

[0064] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com