Low-energy-consumption high-light-intensity annular light-emitting cavity fluorescent lamp

A low-energy, fluorescent lamp technology, applied in the field of fluorescent energy-saving lamps, can solve the problems of increased energy consumption, increased lamp tube diameter, and decreased light efficiency, achieving the effect of increased diameter, increased polygonal sides, and reduced light efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

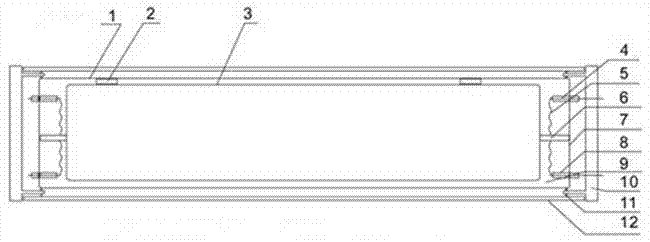

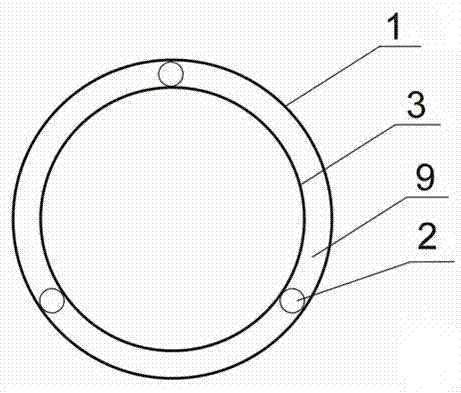

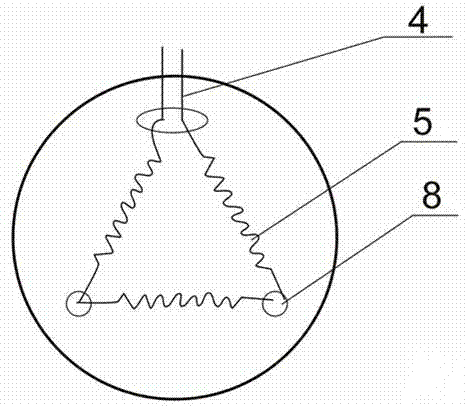

[0024] Depend on Figure 1-3 As shown, 1 in the figure is a phosphor glass outer tube coated on the inside, and a coaxial closed inner tube 3 is arranged on the inner side of the phosphor glass outer tube 1, and the phosphor glass outer tube 1 and the closed inner tube 3 There is also a positioning rod 2 forming an annular gap 9 between them, and an inner end cap 7 with a conductive filament connection line 4 is respectively provided at the two ends of the phosphor glass outer tube 1, and an inner end cap 7 with a conductive filament connection line 4 is provided at the two ends of the phosphor glass outer tube 1. A polygonal filament 5 is also arranged between the inner end cap 7 and the two ends of the closed inner tube 3 (the polygonal filament 5 can be triangular, quadrangular, pentagonal or hexagonal, etc., depending on the diameter of the lamp tube) , the larger the tube diameter, the more sides) the filament holder 8. Between the inner end caps 7 at the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com