Method for manufacturing end milling cutter by using low-cost alloy material

A technology of alloy materials and end mills, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of unsatisfactory high-strength end mills, impact on enterprise production, and high production costs, so as to achieve sufficient market supply and production Low cost and easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below with reference to the drawings and embodiments.

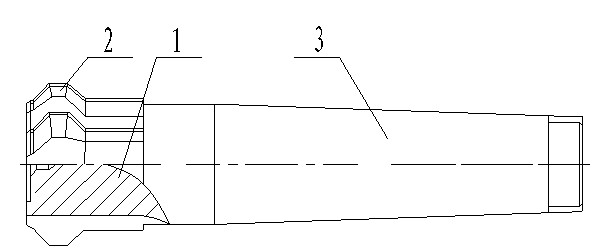

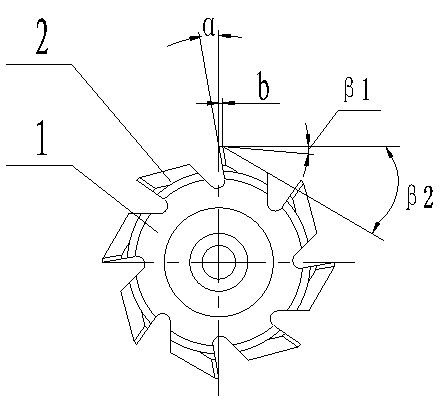

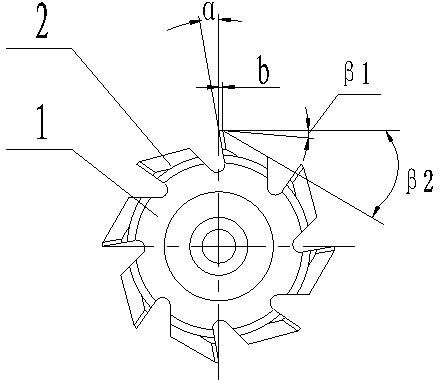

[0012] The embodiment of the present invention: the structure of the present invention is shown as figure 1 with figure 2 As shown, when manufacturing an end mill with a cutter head 1 and a cutter shaft 3, the method of the present invention for manufacturing an end mill using a low-cost alloy material is used for manufacturing. When manufacturing, W6Mo5Cr4V2Al is used to replace the existing The powder metallurgy high-speed steel material is used to make the head 1 part of the end mill, and the teeth 2 of the end mill head 1 part are made as follows:

[0013] Ⅰ) Control the rake angle α of the cutter tooth 2 on the end mill head 1 at an angle of 9°~11°;

[0014] Ⅱ) Make the relief angle of the cutter tooth 2 on the end mill head 1 into a structure composed of two relief angles: a first relief angle β1 and a second relief angle β2, and make the width b of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com