Method for reducing sulfur content in sulfur-containing light oil

A technology of sulfur content and sulfur content, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., to achieve the effects of high yield, simple and environmentally friendly production process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

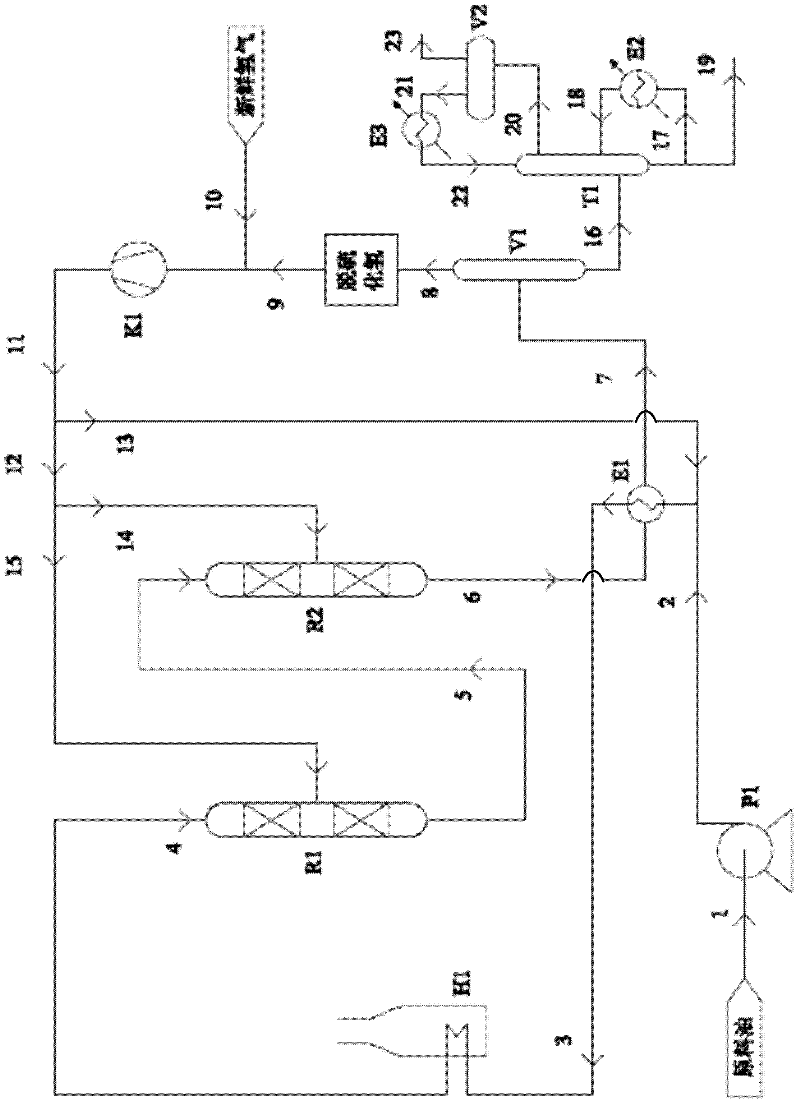

Method used

Image

Examples

Embodiment 1

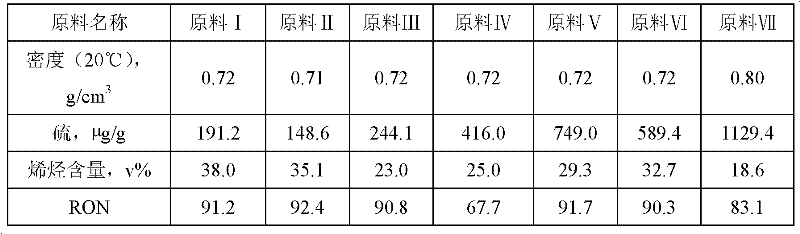

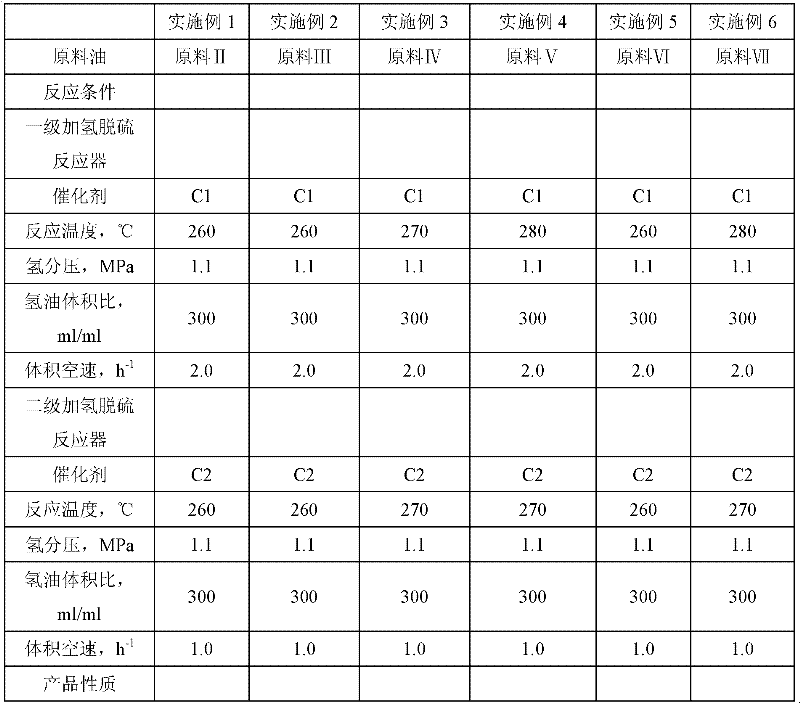

[0041] A catalytically cracked gasoline is used as feedstock II, and its feedstock properties are shown in Table 1. The whole fraction of FCC gasoline is contacted with hydrodesulfurization catalyst C1 in the primary hydrodesulfurization reactor for selective hydrodesulfurization reaction; the effluent of the primary hydrodesulfurization reactor enters the secondary hydrodesulfurization reactor for hydrogenation The desulfurization catalyst C2 undergoes deep hydrodesulfurization reaction, and the reaction effluent from the secondary hydrodesulfurization treatment reactor enters the product tank after being cooled and separated to obtain gasoline products.

[0042] The specific reaction conditions of the primary hydrodesulfurization reactor and the secondary hydrodesulfurization reactor and the properties of the whole distillate gasoline are shown in Table 3. It can be seen from Table 3 that the sulfur content of the product is 24.3 μg / g, and the octane number loss 0.7, the pro...

Embodiment 2

[0044] A catalytically cracked gasoline is used as feed oil III, and its raw material properties are shown in Table 1. The full fraction FCC gasoline is contacted with hydrodesulfurization catalyst C1 in the primary hydrodesulfurization reactor for selective hydrodesulfurization reaction; the material from the primary hydrodesulfurization reactor enters the secondary hydrodesulfurization reactor and Hydrodesulfurization catalyst C2 carries out deep hydrodesulfurization reaction, and the reaction effluent from the secondary hydrodesulfurization treatment reactor enters the product tank after cooling and separation to obtain gasoline products, with sulfur content of 39.6μg / g, olefin content of 20.5v%, RON The loss is only 0.3, and the product yield is greater than 99%.

Embodiment 3

[0046] A catalytically cracked gasoline is used as raw material IV, and its raw material properties are shown in Table 1. The full fraction FCC gasoline is contacted with hydrodesulfurization catalyst C1 in the primary hydrodesulfurization reactor for selective hydrodesulfurization reaction; the material from the primary hydrodesulfurization reactor enters the secondary hydrodesulfurization reactor and Hydrodesulfurization catalyst C2 carries out deep hydrodesulfurization reaction, and the reaction effluent from the secondary hydrodesulfurization treatment reactor is cooled and separated and then enters the product tank to obtain gasoline products with a sulfur content of 41.9 μg / g and an olefin content of 21.3v%. , RON loss 2.7, product yield greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com