Bundle type dyeing machine with double-layer ball shaft bracket structure

A double-layer ball and dyeing machine technology, which is applied in the field of beam dyeing machines, can solve the problems of large footprint of the ball axle frame, low efficiency, and reduction of the footprint of a single-layer ball axle frame, etc., to achieve a reduced footprint , reduce knotting, reduce the effect of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

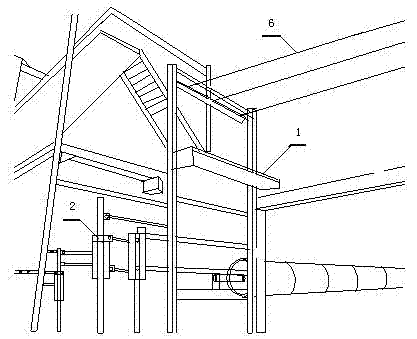

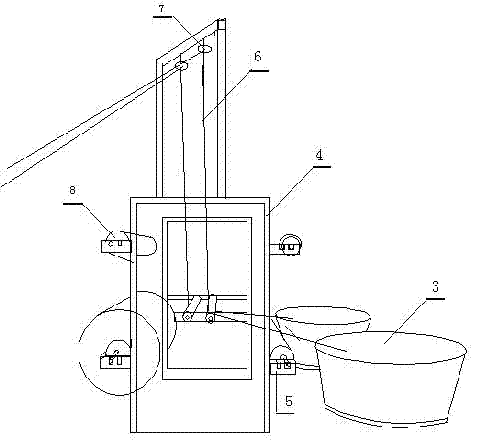

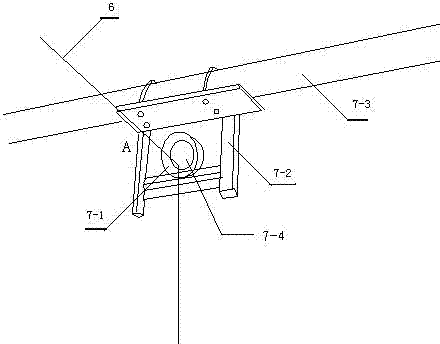

[0014] Such as figure 1 , 2 , 3, the present invention is a beam dyeing machine with a double-deck ball axle frame structure, including a fuselage 1 and a working unit 2, the working unit 2 is provided with at least one group, and its quantity and function can be determined according to the process It is required to be set up in sequence from front to back. The beam dyeing machine composed of different quantities and functions can meet different actual situations according to the needs, with stronger flexibility and wider application. The beam dyeing machine also includes yarn pot 3, Frame 4, one layer of ball creel 5, bunched yarn 6, yarn guide ring 7 and secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com