Section-variable crossed circular tube switching steel column and manufacturing method thereof

A technology of variable cross-section and cross-column, applied in the direction of columns, piers, pillars, etc., can solve the problem of wasted steel consumption, maximize the bearing capacity, avoid butt joints, and have the effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

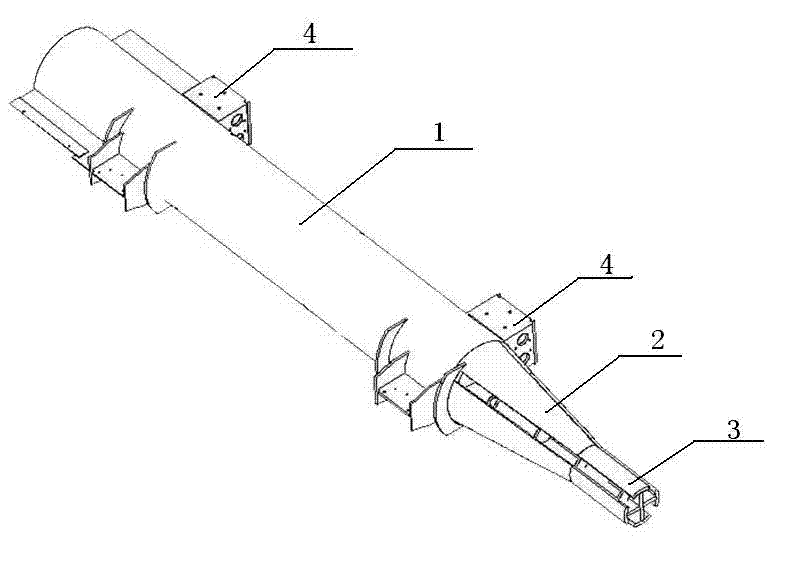

[0033] Such as figure 1 A cross-section steel column with variable cross-section shown includes: an upper circular column 1, a middle conical column 2, a lower circular cross column 3 and a steel corbel 4; the overall shape of the upper circular column 1 is A cylindrical shape; the conical column 2 is a truncated cone; the outer part of the circular cross column is cylindrical as a whole.

[0034] The connection relationship between the above-mentioned main components is: the top of the conical column 2 is assembled and welded together with the lower end of the upper cylindrical column 1, and the bottom end of the conical column 2 is assembled and welded with the upper end of the circular cross column 3; The steel corbel 4 is assembled and welded on the outer surface of the upper circular pipe column 1 .

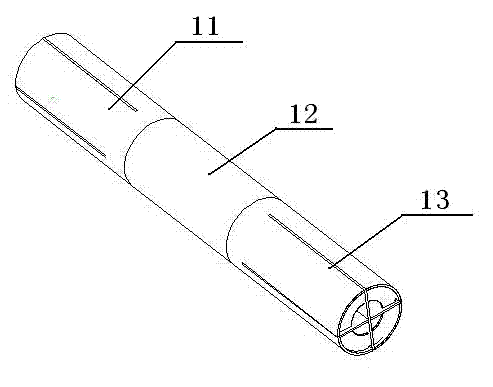

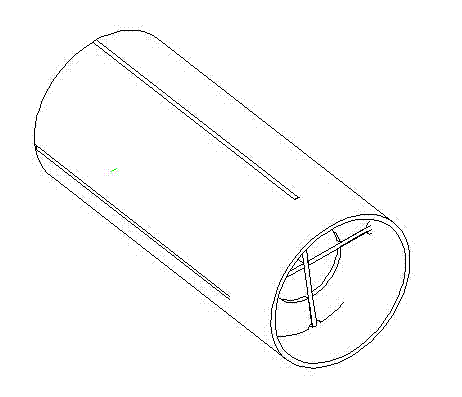

[0035] In the present embodiment, the upper cylindrical pipe column 1 is divided into an upper section 11, a middle section 12 and a lower section 13; the lower section 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com