Flow guide reaction type double-rotor tidal current energy water turbine

A dual-rotor, tidal energy technology, applied in the direction of reaction engine, tidal flow/damless hydropower, mechanical equipment, etc., can solve the problems of easy damage, unstable operation, small power generation of hydro turbines, etc., to increase the rotation speed and energy. The effect of high utilization rate and increased power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

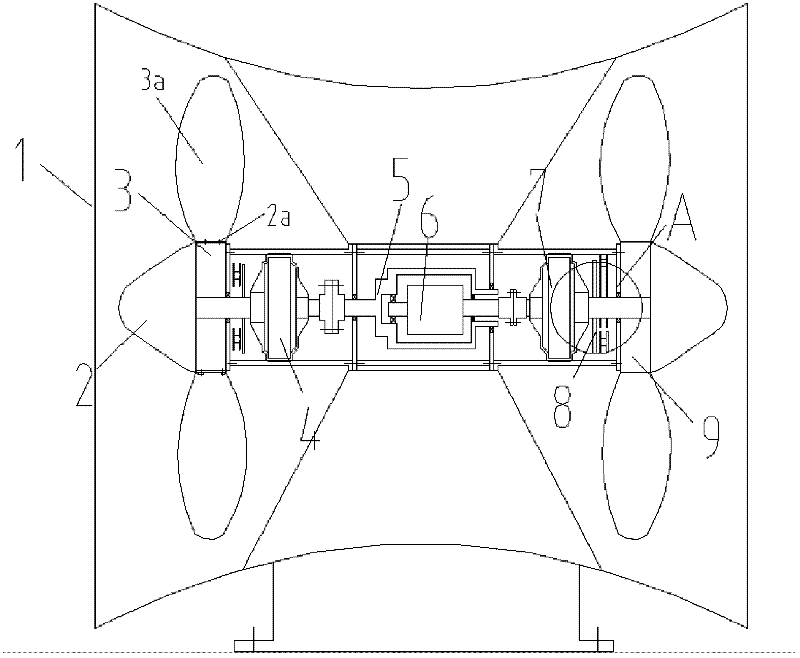

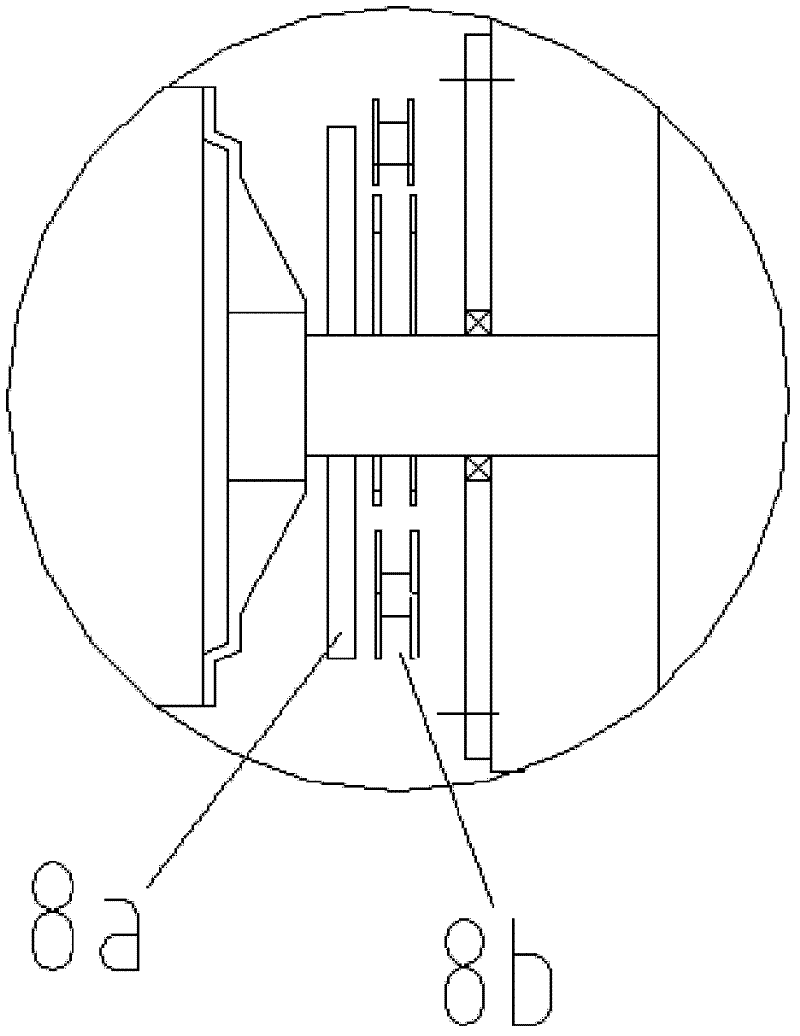

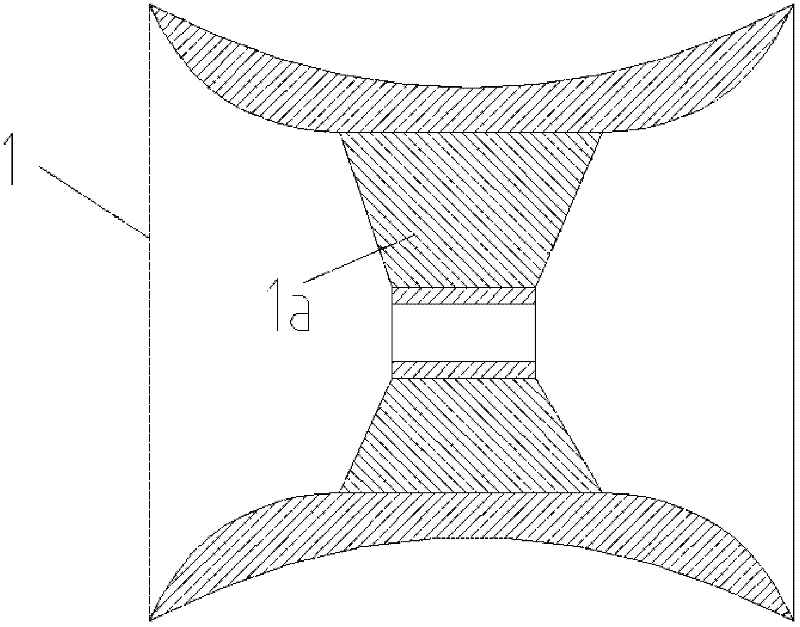

[0019] combine Figure 1~3 ,Such as figure 1 The diversion type dual-rotor tidal current energy generation hydroturbine shown in the present invention includes a diversion cover 1 installed on the periphery, a diversion cap 2, an upstream impeller 3, an upstream speed-up gearbox 4, an outer rotor 5 of a generator, and an inner rotor of the generator. The rotor 6, the downstream speed increasing gear box 7, the braking device 8 and the downstream impeller 9 constitute. The shroud 1 is connected to the outer casing of the water turbine through the shroud bracket 1a, the hub of the upstream impeller 3 is connected to the input shaft of the upstream speed-up gearbox 4 through a key, and the downstream impeller 9 is connected to the downstream speed-up gearbox 7 through a key The centers of the upstream impeller 3 and the downstream impeller 9 are on the same axis, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com