Lateral restraining device for load test of steel-structure compression member

A technology for loading test and compression components, which is applied in the field of steel structures in structural engineering, can solve problems such as the inability to arrange large-scale reaction frames, difficulty in installing reaction frames, and limited number of supports, and achieves easy processing, simple structure, and reduced The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

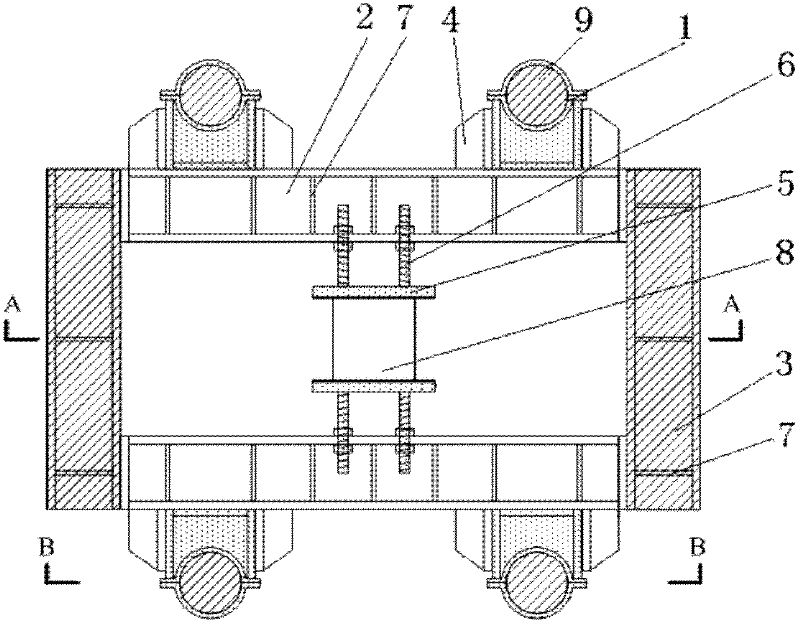

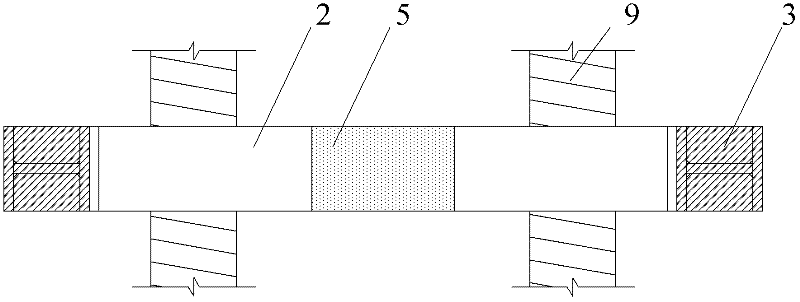

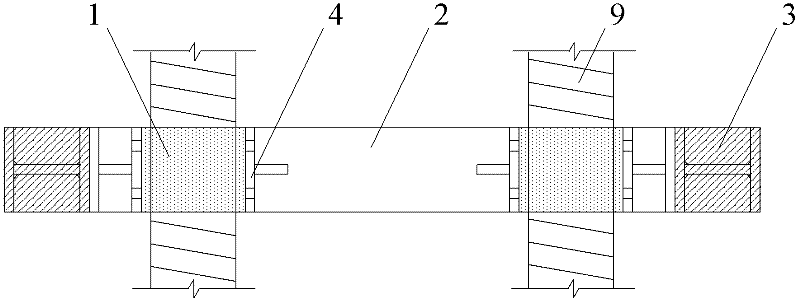

[0020] figure 1 It is a structural top view schematic diagram of an embodiment of a lateral restraint device for a loading test of a steel structure compression member, figure 2 and image 3 respectively figure 1 Structural sectional view along A-A direction and structural sectional view along B-B direction. The lateral restraint device of the steel structure compression member loading test is a detachable structure, which consists of a screw clamp 1, a supporting beam 2, a self-balancing beam 3, a screw clamp base 4, a specimen splint 5 and a splint screw 6. Both the support beam 2 and the self-balancing beam 3 are H-shaped steel structures. There are 4 holes in the middle part of the inner flange of the supporting beam 2. The inner flanges of the front and rear two supporting beams 2 are opposite and parallel to each other, and the inner fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com