Cable pipeline construction method and air bag applied in the method

A pipeline construction and cable technology, applied in the direction of optical fiber/cable installation, etc., can solve the problems of optical cable affecting transmission quality, poisonous gas poisoning, etc., and achieve the effect of good sealing effect, high reuse rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

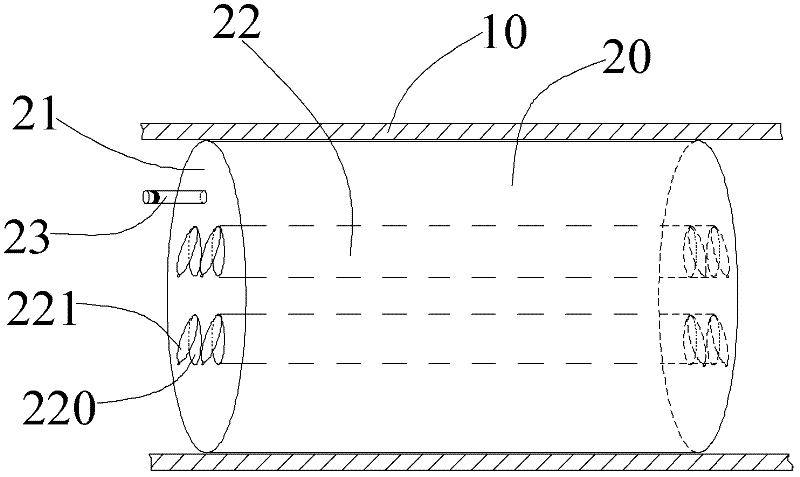

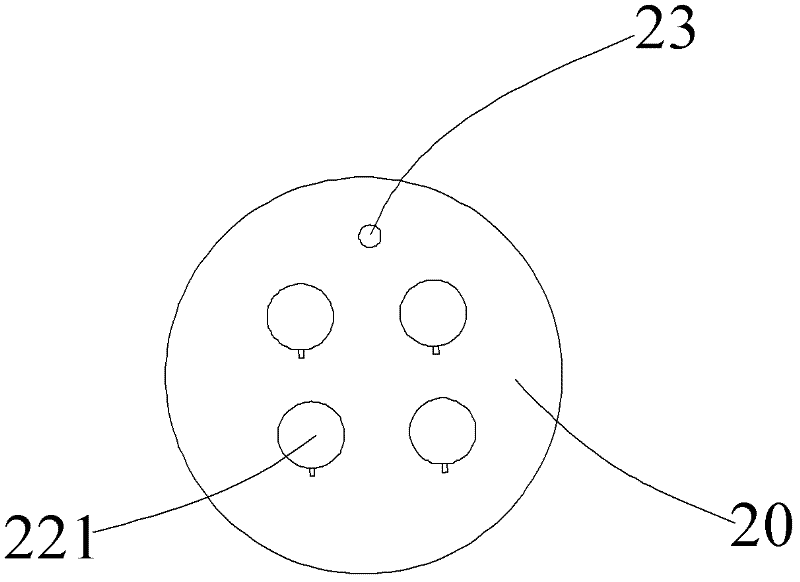

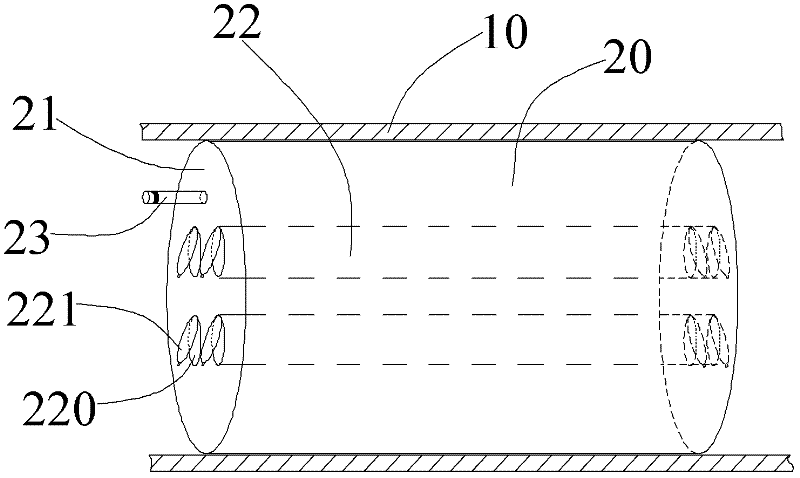

[0023] Please refer to figure 1 and figure 2 Specifically, the new cable duct construction method provided by the present invention is to seal each hole of the corrugated duct 10 with a sealing device at the pipe opening in the manhole after the double-wall corrugated duct 10 is completed, and the sealing device is a An inflatable airbag 20 is mainly made of rubber material and has strong stretchability. When the airbag 20 is not inflated, it is shriveled and looks like a thin cake. End faces 21 are provided at both ends, and one end face is provided with a Protruding air hole 23. There are several through holes 22 inside the airbag 20 , and each through hole has a round hole 220 on the end surface 21 . There is a spring lock 221 on each round hole 220, which has an automatic closing function, that is, it is closed in a natural state, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com