Full-functional belting rotary disk

A turntable and tape reel technology, which is applied in laying solid insulation and other directions, can solve the problems that the tape tape turntable manufacturing technology cannot be realized, the imported tape tape machine is expensive, and the maintenance cost is high. The effect of good quality and improved strapping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

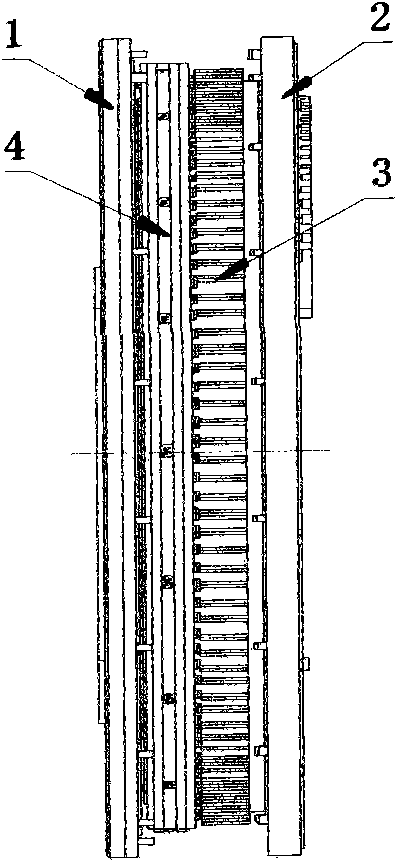

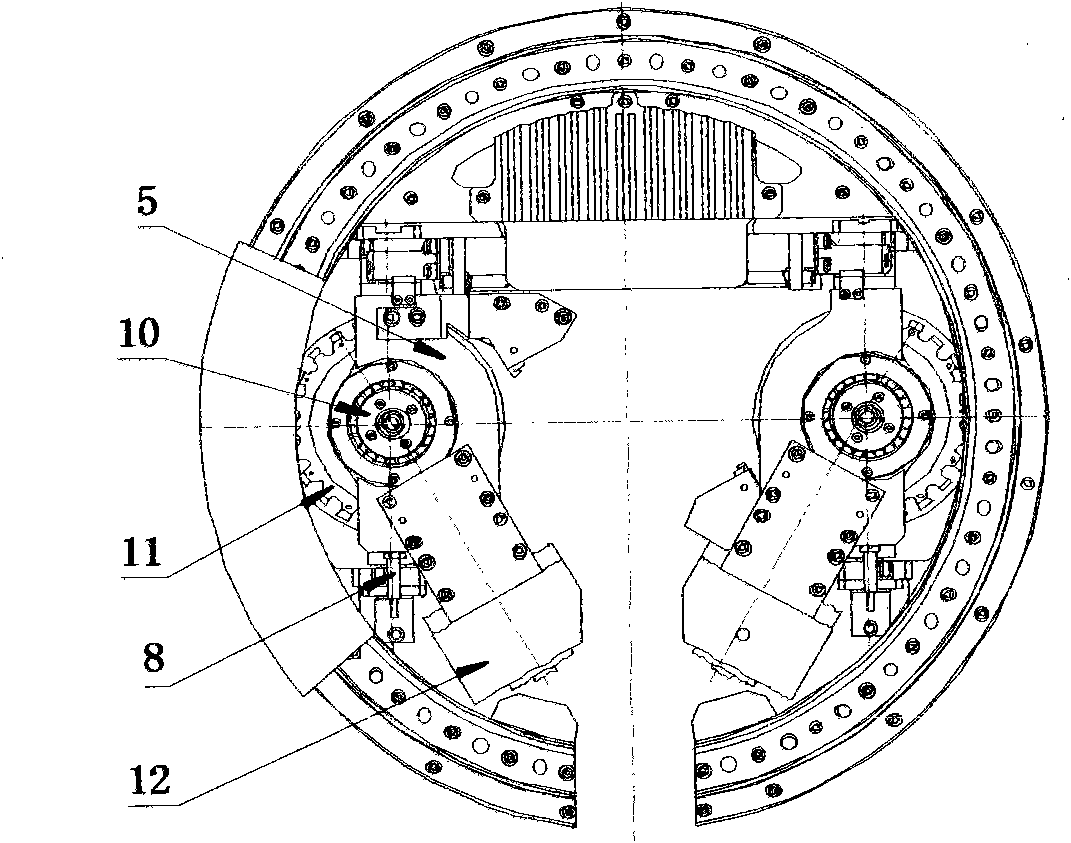

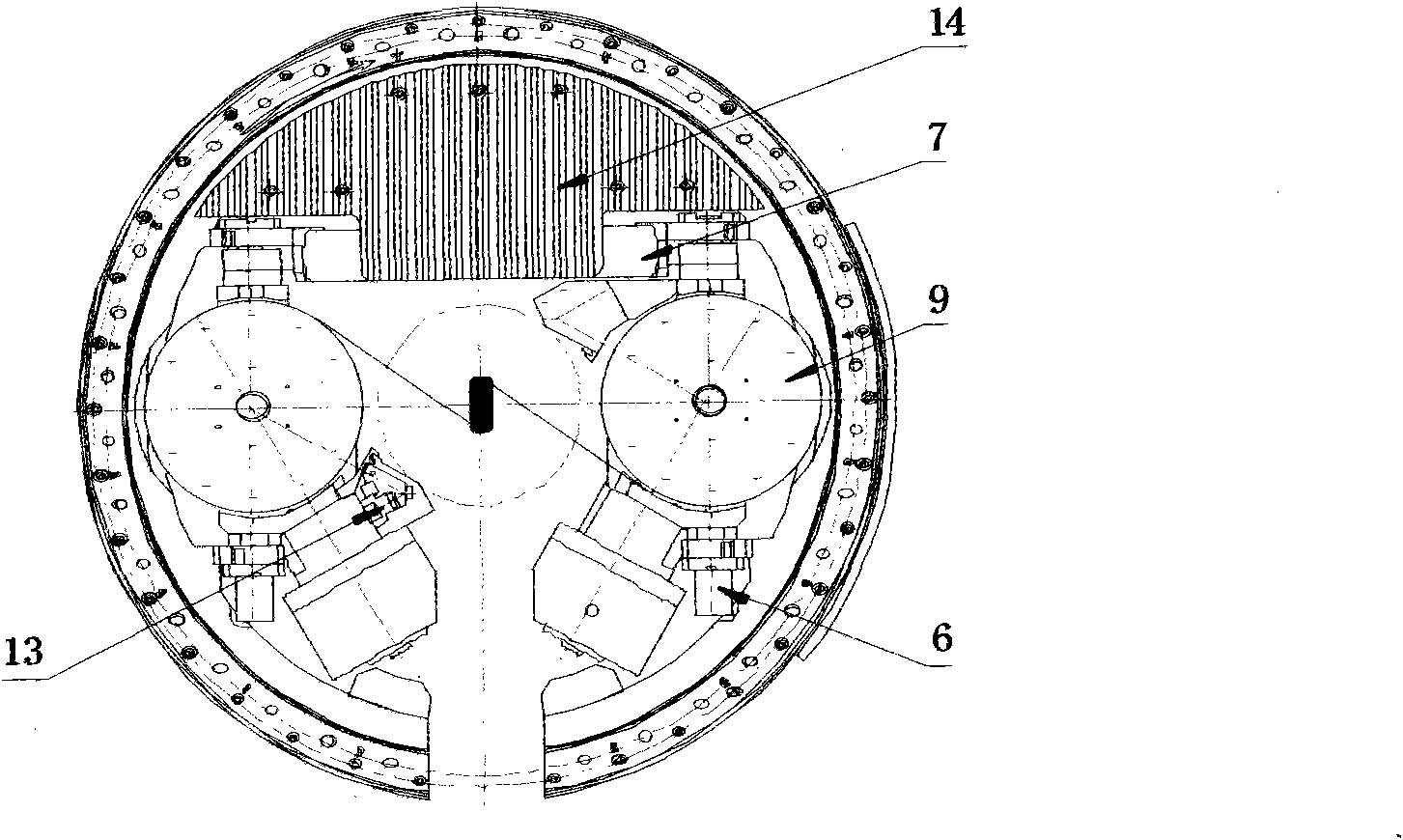

[0031] refer to figure 1 As shown, it is a side view of the full-featured taping turntable. The full-featured taping turntable is the core component of the CNC taping machine and is installed in the casing of the taping head of the CNC taping machine. Its appearance is a disk Shaped hollow structure with openings in the radial direction, the workpiece can be directly loaded from the openings. The belt turntable includes a front stop ring assembly 1 , a rear stop ring assembly 2 and a chainring assembly 3 .

[0032] Since the coil of the stator winding is a closed structure, the taping rotary disc can only move in the open position of the coil when it is working. In order to prevent interference with the opposite coil and meet the wrapping near the nose, the taping rotary disc must follow the minimum radius of gyration and minimum thickness. to design. The sprocket assembly 3 and the taping head housing are connected through the front stop ring assembly 1 and the back stop ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com