Extrusion processing method and extrusion processing device

A technology of extrusion processing and extrusion rod, which is applied in the field of manufacturing raw material tubes for photosensitive drum bases, and can solve problems such as poor appearance of extrusion parts, poor air entrapment, and poor appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

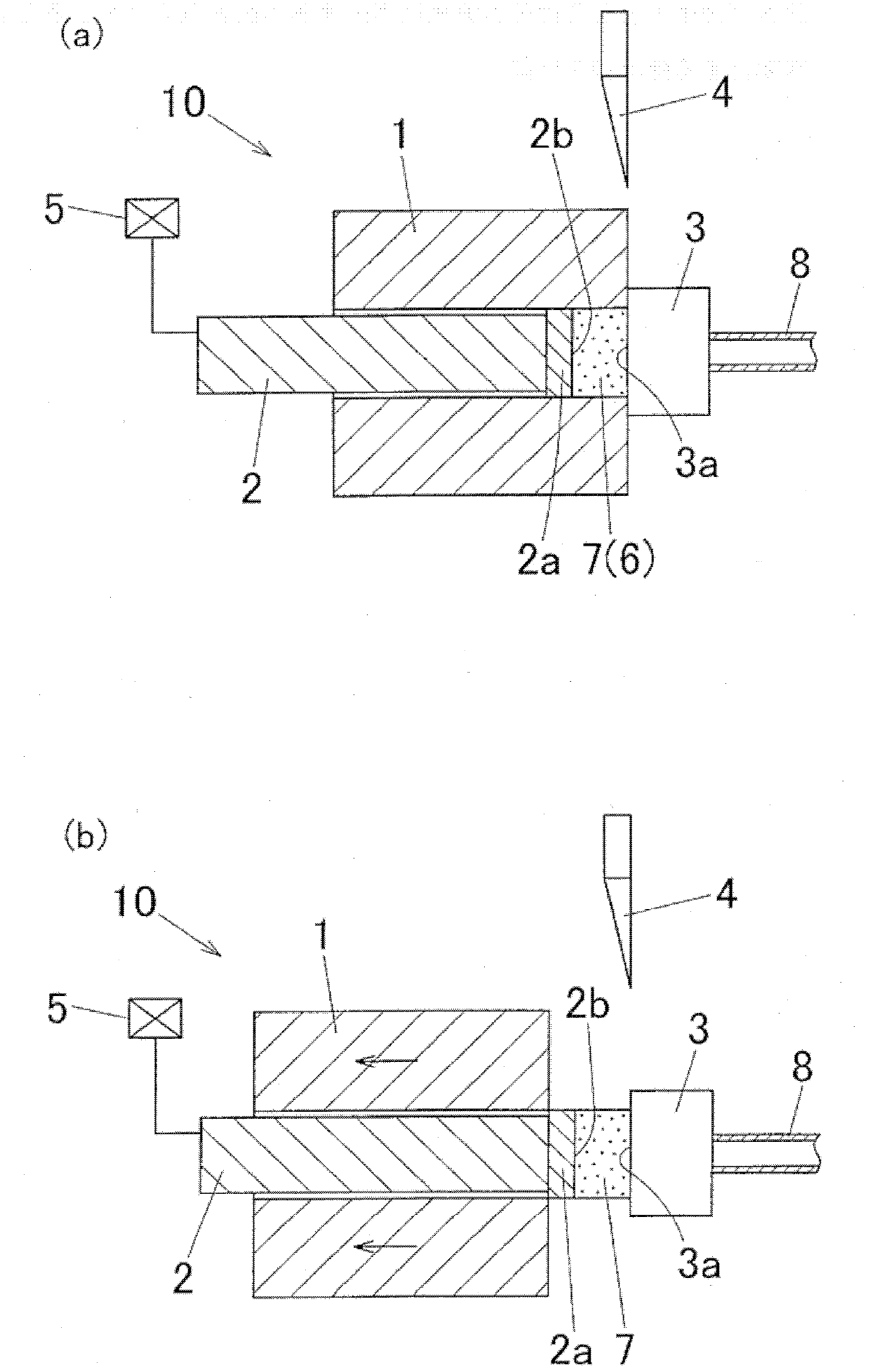

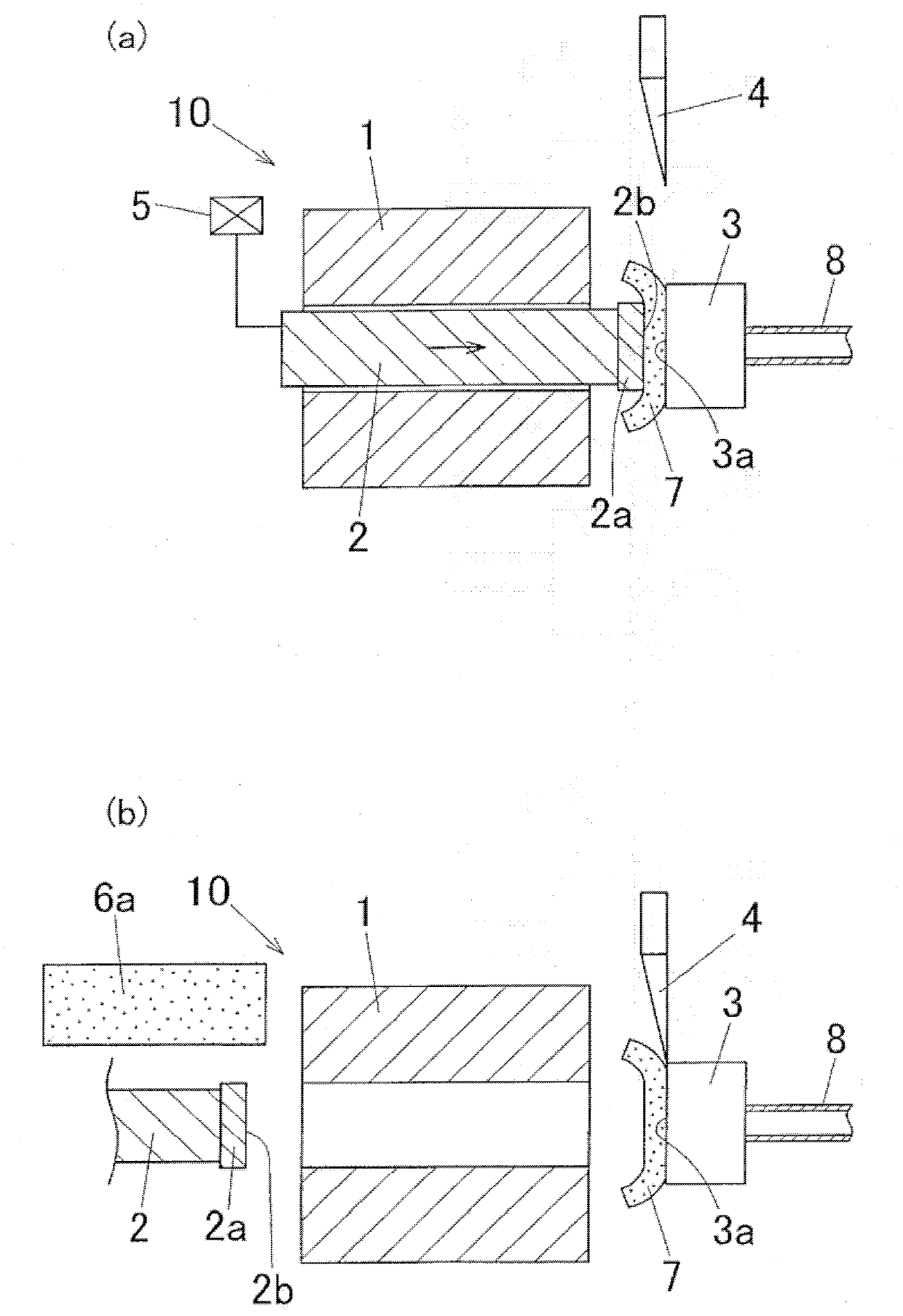

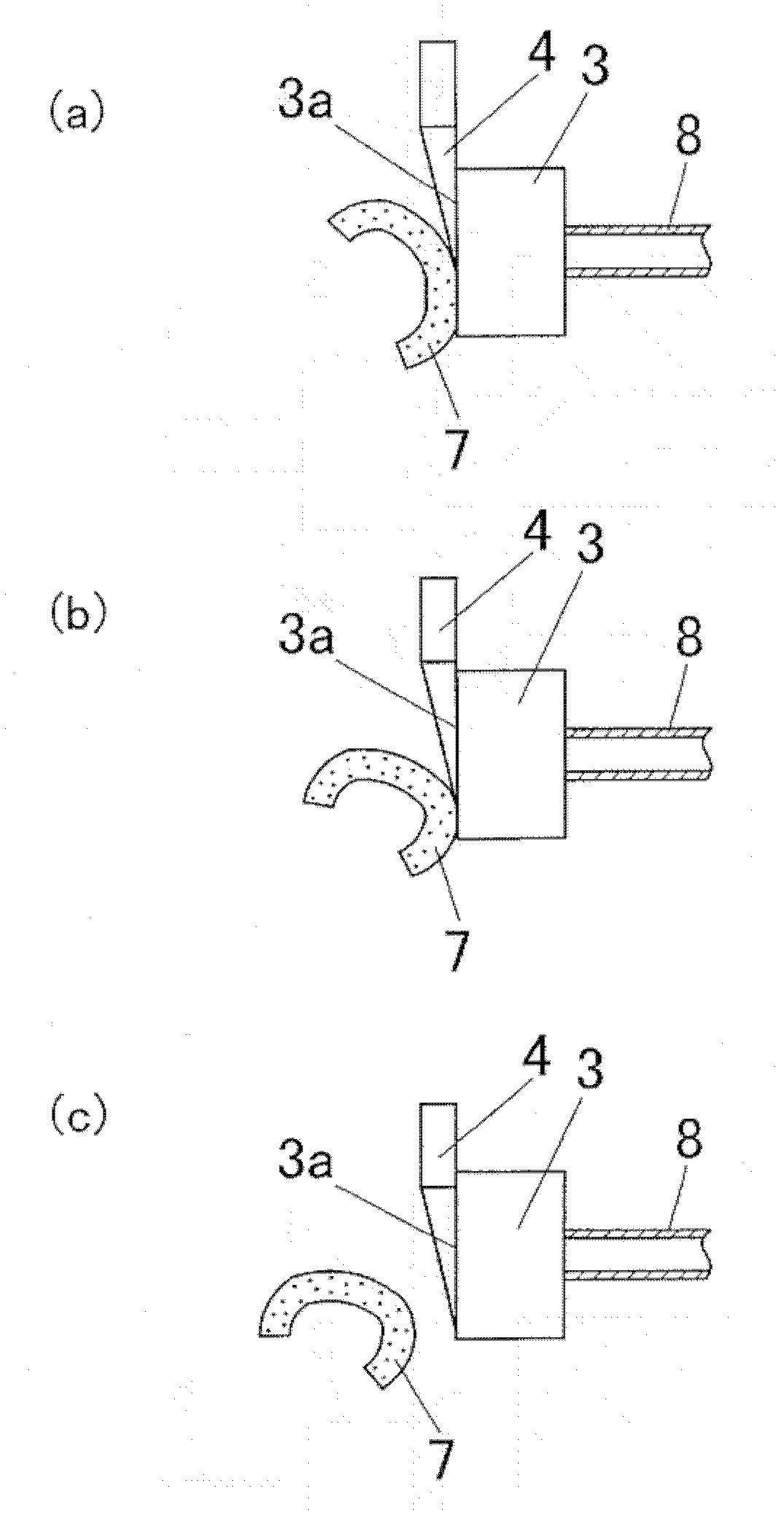

[0042] Next, an embodiment of the present invention will be described below with reference to the drawings.

[0043] Figure 1~3 It is a figure for demonstrating the extrusion processing method and extrusion processing apparatus concerning one embodiment of this invention. exist figure 1 In , reference numeral 10 denotes an extrusion processing device according to an embodiment of the present invention. Specifically, the extrusion processing device 10 is a direct extrusion processing device, and is a device for manufacturing a metal extrusion product as the extrusion product 8 . The material of the extruded material 8 is metal, specifically, aluminum, for example. This extruded member 8 is a hollow extruded member (for example: a pipe) used for a raw material tube for a photosensitive drum base, an OA member, a building material, an exterior material, etc., and has a hollow portion continuously extending in the extruding direction. extrusions. In this embodiment, the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com