Rubber shoe drying machine with high-power lamps

A high-power, drying machine technology, applied in the direction of shoemaking machinery, footwear, clothing, etc., can solve the problems of waste of resources, increase of financial expenditure, troublesome operation, etc., to save production costs, increase work efficiency and production quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

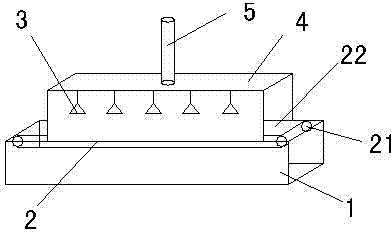

[0010] figure 1 It shows an embodiment of a high-power lamp dryer for rubber shoes of the present invention: it includes a frame 1, a transmission mechanism 2 arranged in the frame 1, a machine cover 4 installed above the frame 1, and a device for driving the transmission mechanism 2. The motor, the transmission mechanism 2 includes a roller 21 and a conveyor belt 22, the roller 21 is installed at the two ends of the frame 1, the roller 21 surface is sleeved with a conveyor belt 22, and the inside of the cover 4 is located at the top of the conveyor belt 22. Some drying lamps 3 for drying, the power of the drying lamps 3 is greater than 200W, the upper end surface of the machine cover 4 is provided with a ventilation pipe 5, the number and intensity of the drying lamps can be adjusted by customs clearance, and the rubber shoes of any different materials can be processed. Drying is fast and effective, which greatly improves the efficiency of the entire production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com