Double-valve parallel mode adjusting and locking system for two-plate injection molding machine

A technology of injection molding machine and parallel connection, which is applied in the field of mold adjustment and clamping system of double-valve parallel two-platen injection molding machine, which can solve the problems of inconvenient control, long mold adjustment time, complicated mold clamping process, etc. The effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

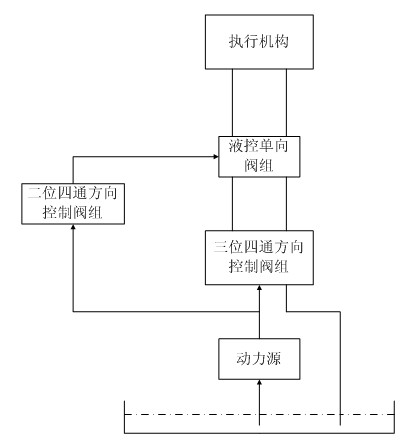

[0021] Such as figure 1 As shown, the present invention includes a main oil circuit module and a control oil circuit module. The main oil circuit module includes: a power source, a three-position four-way directional control valve group, a hydraulic control check valve group and an actuator; the control oil circuit module includes two Four-way directional control valve group.

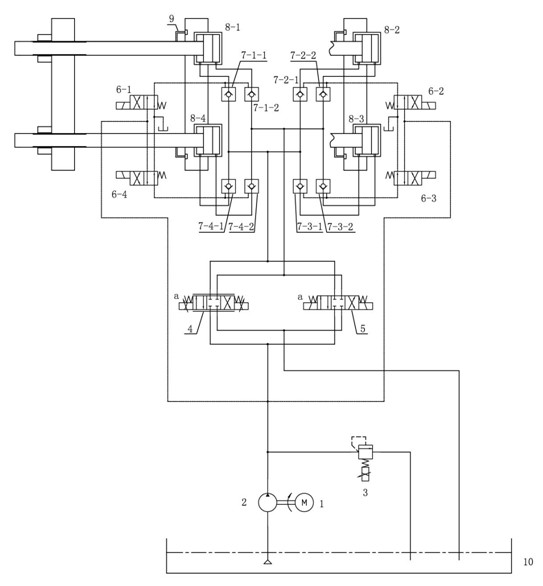

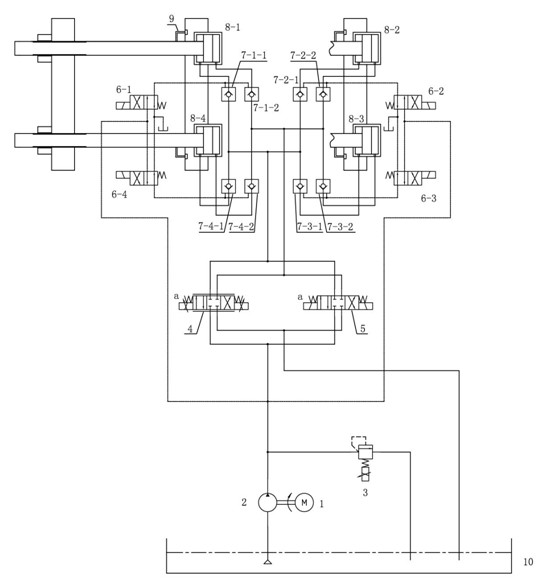

[0022] Such as figure 2 As shown, the power source includes a servo motor 1, a quantitative hydraulic pump 2, a proportional overflow valve 3 and an oil tank 10, and the servo motor 1 drives the quantitative hydraulic pump 2 to provide power for the present invention; the inlet of the proportional overflow valve 3 is connected to the quantitative hydraulic pump 2 The outlet of the proportional relief valve 3 is connected with the outlet of the oil tank 10;

[0023] The outlet of the power source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com