Porcelain plate painting blasting and carving and producing and using method

A technology of porcelain plate painting and porcelain plate, which is applied to the special technology of art painting, the technology for producing decorative surface effects, decorative art, etc., to achieve the effect of easy control, high work efficiency, and solution to hardness and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in combination with specific embodiments.

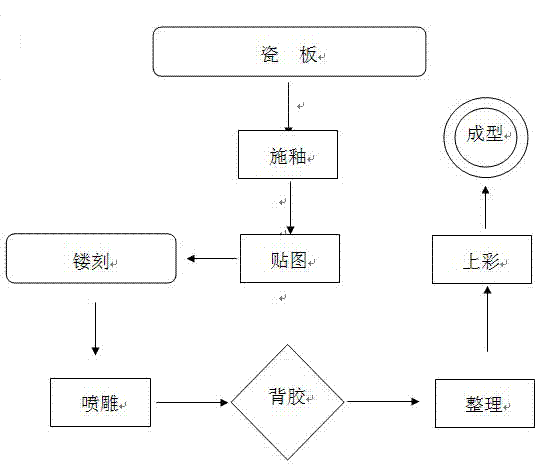

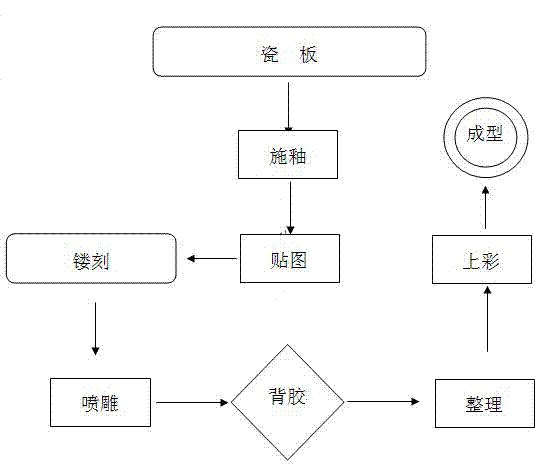

[0012] Select and prepare a porcelain plate, apply glaze on its surface, print the designed pattern to be engraved into a cut-out texture, stick the texture on the glaze of the porcelain plate, engrave the texture, spray engrave some areas, that is, perform sandblasting, Remove the surface of the hollowed-out part of the map. After sandblasting, the glaze layer is peeled off to form a rough color filling area, and the residual map is removed. Then, the adhesive and the explosion-proof protective film are laid on the back of the carved surface of the porcelain plate, and then the appearance of the porcelain plate is sorted out. When in use, fill the color paint in the color filling area, and finally shape it.

[0013] Glaze 1-3 layers on the surface of the porcelain plate.

[0014] Porcelain plates of different shapes and sizes, or those that have been glazed, do not need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com