Phosphorus-free corrosion and scale inhibitor used for industrial circulation cooling water

A technology of circulating cooling water and phosphorus-free corrosion inhibition, applied in the field of phosphorus-free corrosion and scale inhibitor, can solve the problem of no phosphorus-free corrosion and scale inhibitor formula, complex formula, etc., to avoid the problem of water eutrophication, reduce Environmental pollution, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

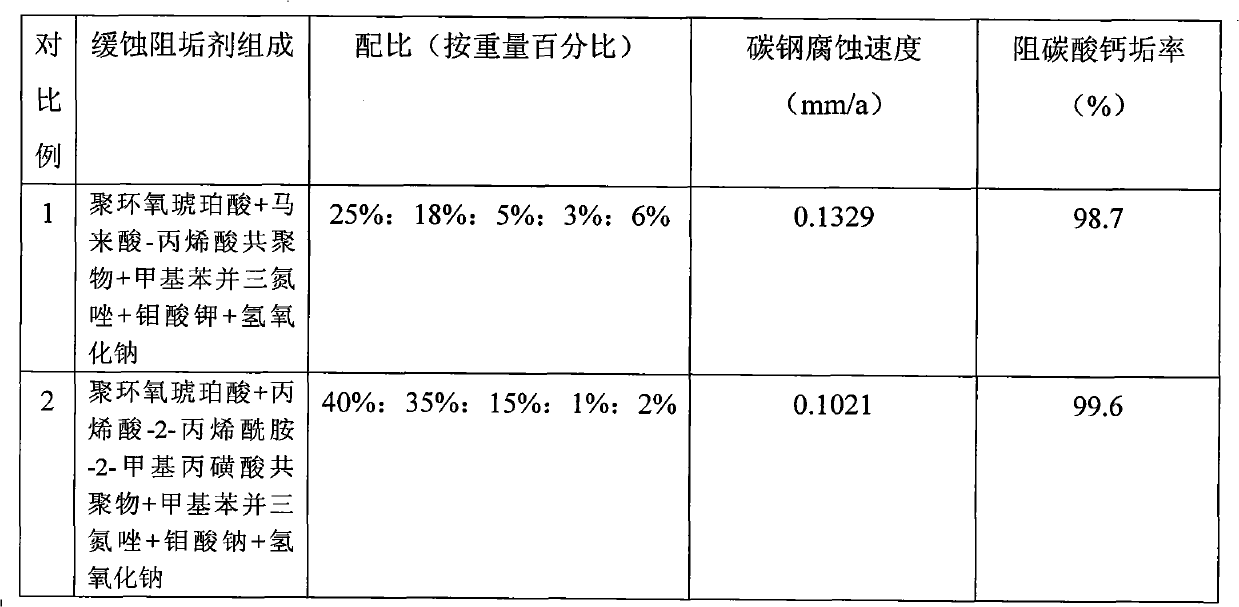

Embodiment 1

[0026] Prepare 100g of phosphorus-free corrosion and scale inhibitor solution: weigh 20g of sodium molybdate and 20g of sodium silicate, add water and stir to dissolve after mixing, then add 20ML of PESA with a concentration of 500g / L, and finally add water to make the weight of the solution 100g , to obtain the desired corrosion and scale inhibitor solution.

[0027] Use 100g of the prepared phosphorus-free corrosion and scale inhibitor solution, and add it to the industrial water to be treated at a concentration of 100mg / L. The effective concentrations of each single component, namely sodium molybdate, sodium silicate, and PESA, are respectively 20mg / L, 20mg / L, 10mg / L.

[0028] Raw water quality of the above-mentioned industrial water: total hardness 270mg / L, ammonia nitrogen 0mg / L, calcium hardness 43.1mg / L, total alkalinity 468.9mg / L, Cl - 191.1mg / L, SO 4 211.2mg / L, pH 7.3, COD 27, turbidity 0.4, petroleum 8.5mg / L, conductivity 2360μS / cm, Fe 2+ 0.3mg / L.

Embodiment 2

[0030] Prepare 100g of phosphorus-free corrosion and scale inhibitor solution: weigh 18g of sodium molybdate, 10g of sodium silicate, and 12g of sodium gluconate, add water and stir to dissolve after mixing, then add 24ML of PESA with a concentration of 500g / L, and finally add water to make The weight of the solution is 100g, and the desired corrosion and scale inhibitor solution is obtained.

[0031] Add 100g of the prepared phosphorus-free corrosion and scale inhibitor solution to the industrial water to be treated at a concentration of 100mg / L. Concentrations are 18mg / L, 10mg / L, 12mg / L, 12mg / L respectively.

[0032] Raw water quality of industrial water: total hardness 27mg / L, ammonia nitrogen 0mg / L, calcium hardness 8.1mg / L, total alkalinity 1613mg / L, chloride ion 81mg / L, sulfate radical 3.1mg / L, pH 8.5, COD 35, turbidity Degree 1.2, petroleum 10.7mg / L, conductivity 3120μS / cm, Fe 2+ 0.1mg / L.

Embodiment 3

[0034] Prepare 100g of phosphorus-free corrosion and scale inhibitor solution: weigh 5g of sodium molybdate, 25g of sodium silicate, and 10g of sodium laurate, add water and stir to dissolve after mixing, then add 20ML of PESA with a concentration of 500g / L, and finally add water to make The weight of the solution is 100g, and the desired corrosion and scale inhibitor solution is obtained.

[0035] Add 100g of the prepared phosphorus-free corrosion inhibitor solution to the industrial water to be treated at a concentration of 100mg / L. The effective concentrations of each single component, namely sodium molybdate, sodium silicate, sodium laurate, and PESA, are respectively 5mg / L, 25mg / L, 10mg / L, 10mg / L.

[0036] The raw water quality of industrial water is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com