Preparation method of modified rubber powder, rubber powder modified asphalt and mixture and preparation method thereof

A technology of modified rubber powder and modified asphalt, used in building thermal insulation materials, building components, buildings, etc., can solve the problem that the performance of asphalt mixture cannot be fundamentally improved, and the swelling and Rapid dispersion, insufficient swelling time of rubber powder, etc., to achieve the effect of shortening wet processing time, high cost performance and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

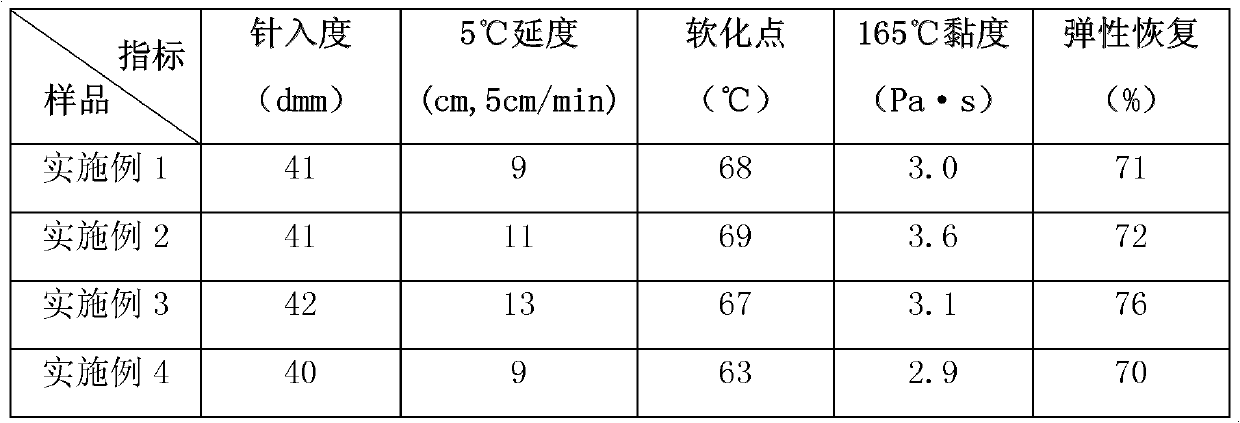

Embodiment 1

[0034] In parts by mass, 3 parts of PE-G-MAH were added to 100 parts of base asphalt, and modified by a high-shear emulsifier at 170°C to obtain modified asphalt. Spray 30 parts of modified asphalt into 100 parts of 40-mesh waste rubber powder, stir at a high speed of 2500r / min for 5 minutes at a temperature of 100°C, and cool with air for 3 minutes. When the temperature drops to 45°C, continue stirring for 5 minutes , to obtain high-performance and high-dispersion modified rubber powder; then 20 parts of modified rubber powder and 100 parts of base asphalt were mixed at 150 ° C, and stirred at a high speed of 600 r / min for 20 minutes to obtain waste rubber powder modified asphalt binder.

Embodiment 2

[0036]In parts by mass, 3 parts of PE-G-MAH were added to 100 parts of base asphalt, and modified by a high-shear emulsifier at 170°C to obtain modified asphalt. Spray 30 parts of modified asphalt into 100 parts of 40-mesh waste rubber powder, stir at a high speed of 2500r / min for 5 minutes at a temperature of 100°C, and cool with air for 7 minutes. When the temperature drops to 45°C, add 2 parts of glass Microbeads, continue to stir for 5 minutes to obtain high-performance and high-dispersion modified rubber powder; then mix 20 parts of modified rubber powder with 100 parts of base asphalt at 150 ° C, and stir at 600 r / min for 20 minutes to obtain waste rubber Powder modified asphalt binder.

Embodiment 3

[0038] In parts by mass, 5 parts of EVA was added to 100 parts of base asphalt, and modified by a high-shear emulsifier at 150° C. to obtain modified asphalt. Spray 10 parts of modified asphalt into 100 parts of 80-mesh waste rubber powder, stir at a high speed of 1500r / min for 15 minutes at a temperature of 120°C, and cool with air for 10 minutes. When the temperature drops to 40°C, add 3 parts of silicon Alginate, continue to stir for 10 minutes to obtain high-performance and high-dispersion modified rubber powder; then mix 20 parts of modified rubber powder with 100 parts of base asphalt at 170 ° C, and stir at 1000 r / min for 20 minutes to obtain waste rubber Powder modified asphalt binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com