High-concentration rubber powder modified asphalt mixture and preparation method thereof

The technology of modified asphalt and mixture is applied in the field of high-concentration rubber powder modified asphalt mixture and its preparation, which can solve the problems of unscientific influence of rubber powder modified asphalt mixture, long processing cycle, limited swelling of asphalt, etc. Achieve great social significance and industry value, save energy and cost, and achieve the effect of large filling amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

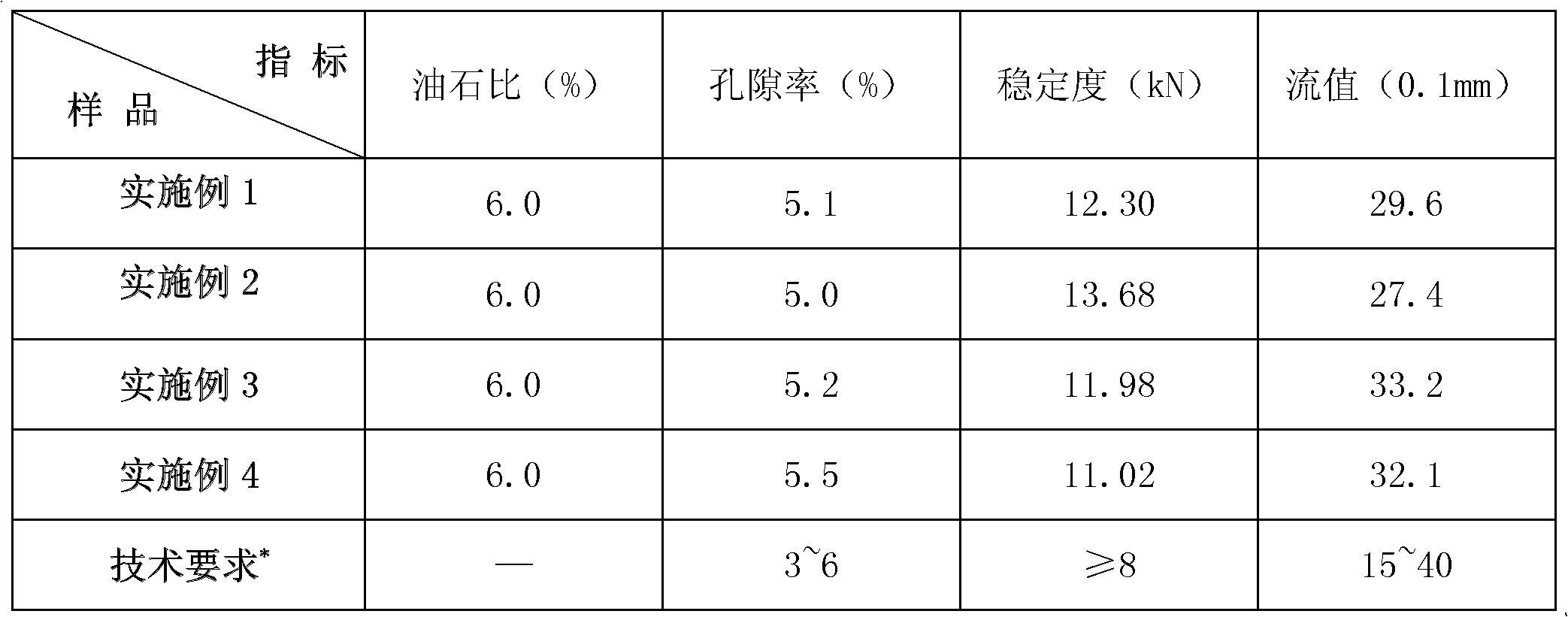

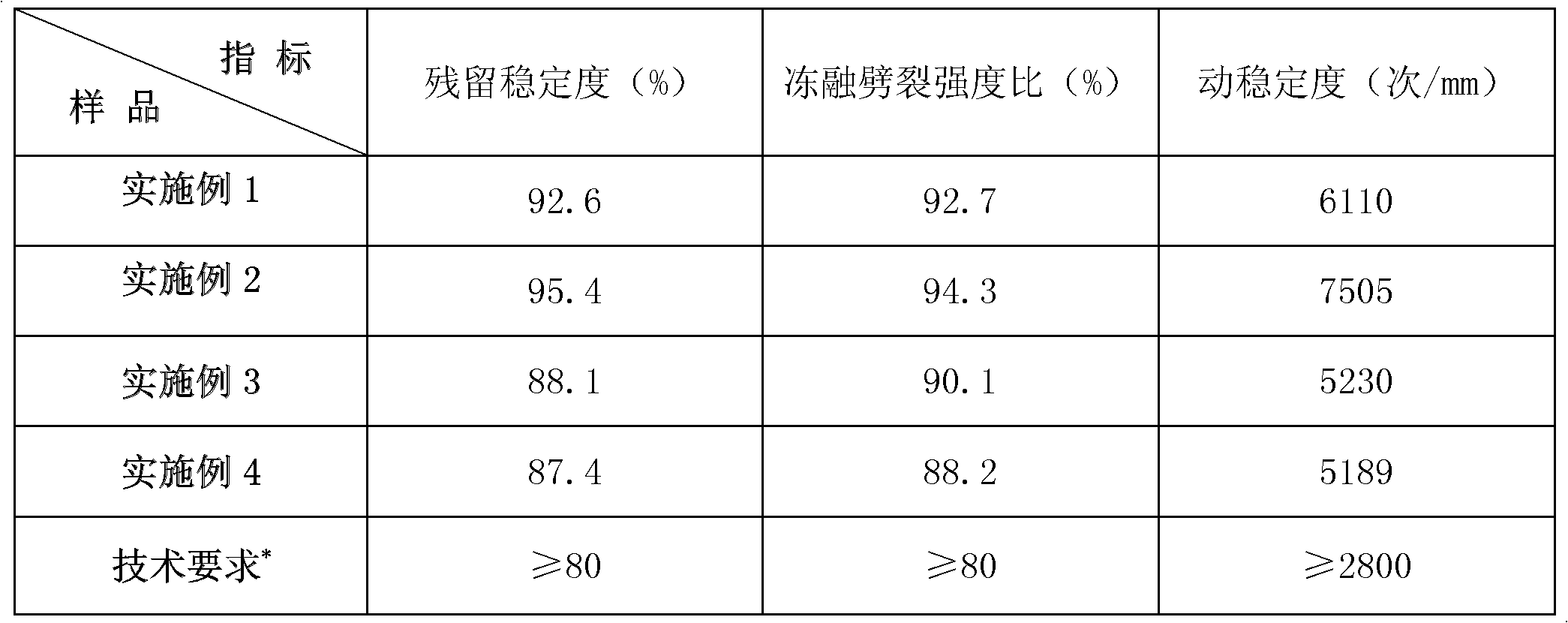

Examples

Embodiment 1

[0032] According to the number of parts by mass, put 100 parts of waste rubber powder in the reactor (commercially available product with high-speed stirring, exhaust, spraying and heating functions), first stir at 400r / min at low speed for 3min, and then at 600r / min for 1min at high speed , and heat up to 45°C to discharge impurities such as water vapor and dust adhering to the surface of the rubber powder, and spray 45 parts of filling barrier agent (silicone oil: linolenic acid = 2:1) preheated to 50°C into the above waste rubber powder In the process, at a temperature of 55°C, stir at a high speed of 1200r / min for 5min, adopt the method of blowing air from the bottom, air-cool for 2min, when the temperature drops to 40°C, store for 48h, and then use a double-roller open mill to mix the premixed The rubber powder and 10 parts of filling barrier agent are sheared and blended to speed up the diffusion rate of the modifier. The distance between the rollers is 0.2mm, the tempera...

Embodiment 2

[0035] According to the number of parts by mass, put 100 parts of waste rubber powder in the reactor, first stir at 500r / min at a low speed for 1min, and stir at a high speed of 800r / min for 3min, and raise the temperature to 45°C, and fill 55 parts of the preheated to 50°C (naphthenic oil: industrial oleic acid = 3:1) was sprayed into the above waste rubber powder, stirred at a high speed of 800r / min for 2min, air-cooled for 3min, and stored for 48h after the temperature was lowered to 40°C, and then kneaded with two rollers The machine shears and blends the premixed rubber powder with 15 parts of filling barrier agent, then disperses it, and stores it at room temperature for 48 hours to obtain a modified rubber powder for high-performance and high-filling asphalt. 60 parts of rubber powder, 1 part of reinforcing agent and 100 parts of base asphalt were stirred at 170 °C for 15 minutes at a speed of 800 r / min, and high-speed shearing was performed at 10000 r / min for 45 minutes...

Embodiment 3

[0038] According to the number of parts by mass, put 100 parts of waste rubber powder in the reactor, firstly stir at 400r / min at low speed for 3min, then switch to 800r / min for 3min at high speed, and raise the temperature to 45°C, and preheat 70 parts of waste rubber powder to 60°C Fill the barrier agent (waste plastic pyrolysis oil: debasement asphalt = 4: 1), stir at 800r / min for 2 minutes, air-cool for 5 minutes, store for 48 hours, and then use a double-roller mill to mix the premixed rubber powder with 20 parts of the filling barrier The agent was sheared and blended, then dispersed, and stored for 48 hours to obtain a modified rubber powder for high-performance and high-filling asphalt. Mix 60 parts of rubber powder, 1 part of reinforcing agent and 100 parts of base asphalt at 180°C for 30 minutes at a speed of 1200 r / min, then shear for 45 minutes at a speed of 12000 r / min to obtain waste rubber powder modified asphalt binder.

[0039] The above rubber powder modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com