Low-dust fall vacuum magneto-controlled sputter coating equipment

A technology of vacuum magnetron sputtering and coating equipment, which is applied in the direction of sputtering coating, vacuum evaporation coating, ion implantation coating, etc., which can solve problems such as unstable product quality, decreased production efficiency, and coating waste products, and achieve increased The effect of contact area and adsorption force, reducing the probability of dust falling, and improving the yield of coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

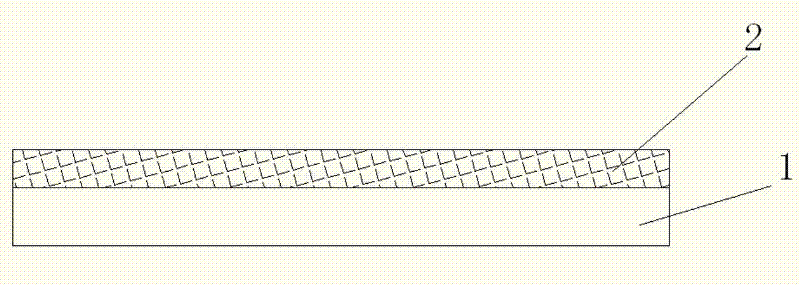

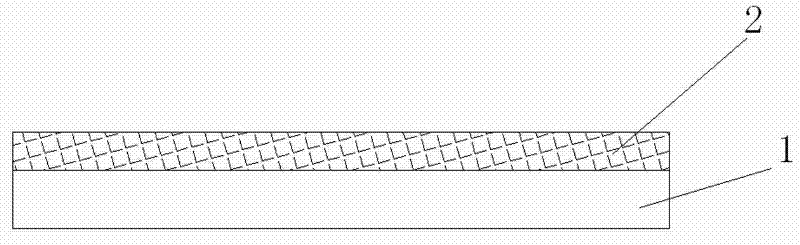

[0012] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

[0013] As shown in the figure, a 12-mesh stainless steel mesh 2 is installed on the cathode shielding plate 1, and the stainless steel mesh 2 is made of 304 stainless steel. The stainless steel mesh 2 can be welded on the surface of the shielding plate 1 by means of electric welding, and it does not have to be tightly welded. The specific welding connection method can be determined according to actual needs and specific conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com